Method for processing low-grade kaolinite ore

A technology of kaolin mines and processing methods, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of uneconomical kaolin mines and large land occupation, and achieve reasonable processing technology design, stable production technology, and improved The effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

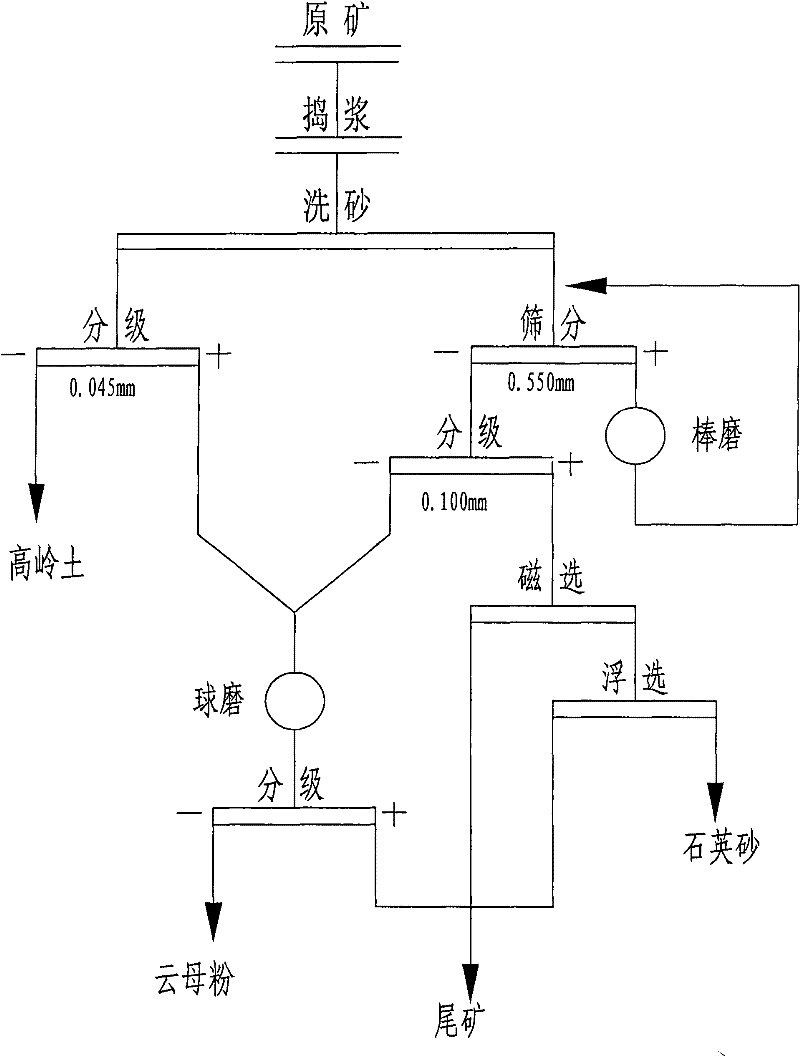

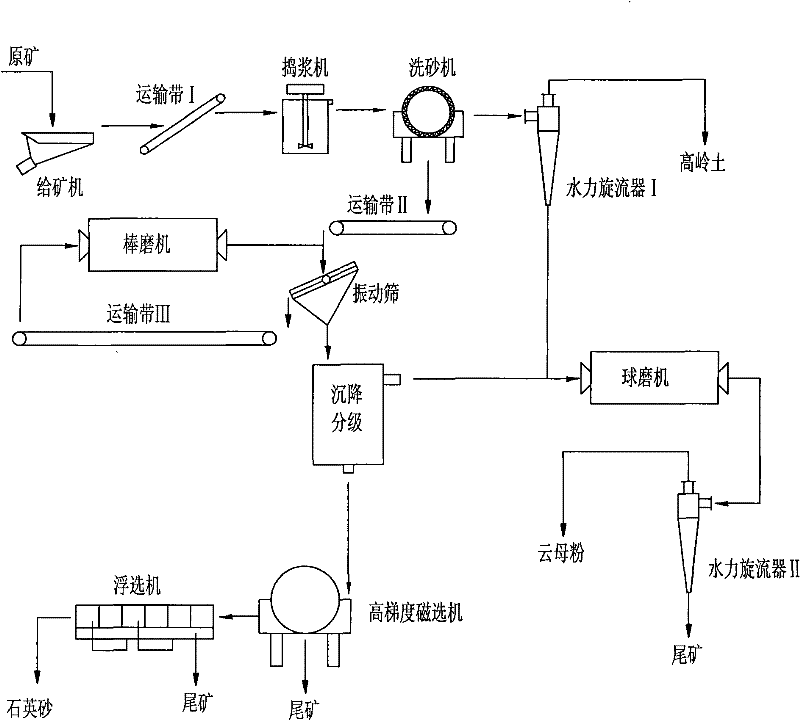

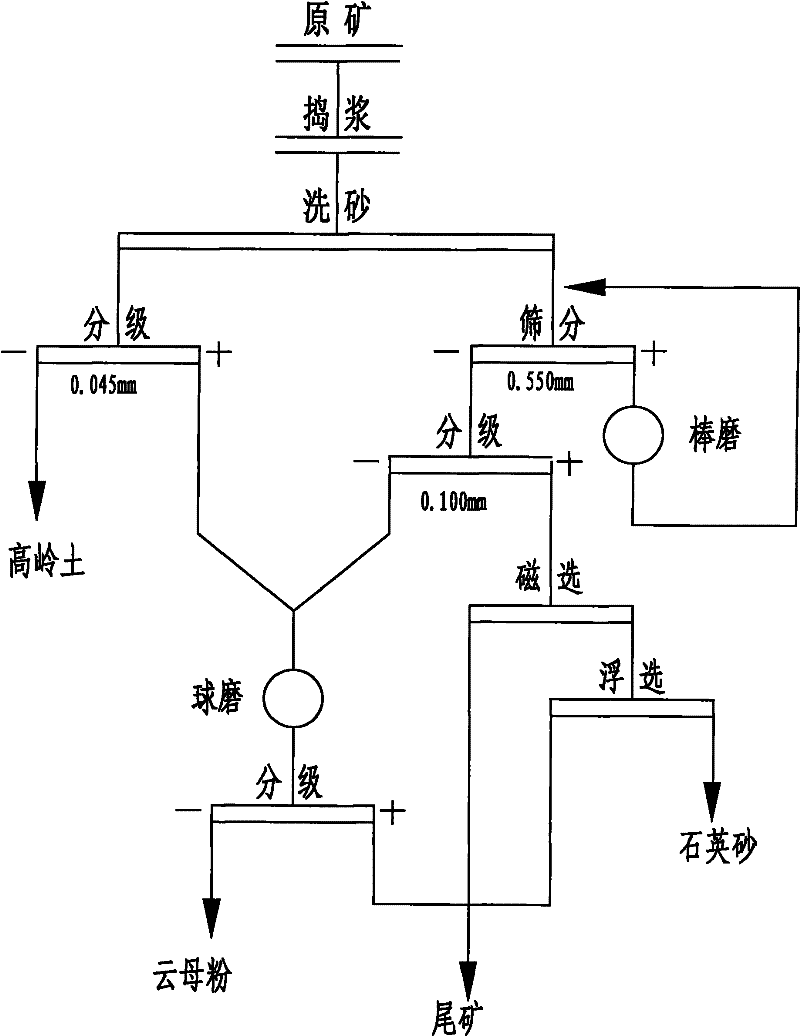

Method used

Image

Examples

Embodiment 1

[0022] Add 3.33 tons of water in the mashing machine pool, transport 5.0 tons of kaolin raw ore in the feeder to the mashing machine pool by belt conveyor I, then add (NaPO 3 ) 6 12.5kg (equivalent to 2.5‰), NaOH 3.5kg (equivalent to 0.7‰), mixed and mashed, the mass concentration of the pulp is 60%, and the ore is washed by a sand washing machine. The fine mortar after washing is 0.50 tons and passed through a hydrocyclone Flow device I is used for classification, the pressure is 0.15MPa, the overflow is 0.40 tons to become 0.045mm grade kaolin products, the bottom flow is 0.10 tons and enters the ball mill; the coarse sand after washing is 4.5 tons, which is conveyed by the conveyor belt II and passed through the 0.55mm vibrating screen for processing Screening, the sieve products larger than 0.55mm enter the rod mill, and the grinding products return to the vibrating screen for sieving, and the cycle continues. Slurry under the sieve adjusts mass concentration to be 45% an...

Embodiment 2

[0028] Add 6.55 tons of water in the mashing machine pool, 8 tons of kaolin raw ore in the feeder will be delivered to the mashing machine pool by belt conveyor I, and then add (NaPO 3 ) 6 8kg (equivalent to 1‰), NaOH 2.4kg (equivalent to 0.3‰), mixed and mashed, the mass concentration of the pulp is 55%, and the ore is washed by a sand washing machine, and the fine mortar after washing is 0.80 tons and passed through a hydrocyclone The pressure is 0.15MPa, the overflow is 0.40 tons to become a 0.045mm grade kaolin product, the underflow is 0.40 tons and enters the ball mill; the coarse sand after washing is 7.2 tons, which is conveyed by the conveyor belt II and passed through a 0.55mm vibrating screen for screening The sieve products larger than 0.55mm enter the rod mill, and the ground products return to the vibrating screen for sieving, and the cycle continues. Slurry under the sieve adjusts mass concentration to be 45% and enters the sedimentation classifier, controls th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com