Injection molding composition

A technology of injection molding and composition, which is applied in the direction of transportation and packaging, metal processing equipment, etc., can solve the problems that the heating and degreasing time must be more than 48 hours, and satisfactory degreasing body cannot be obtained.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

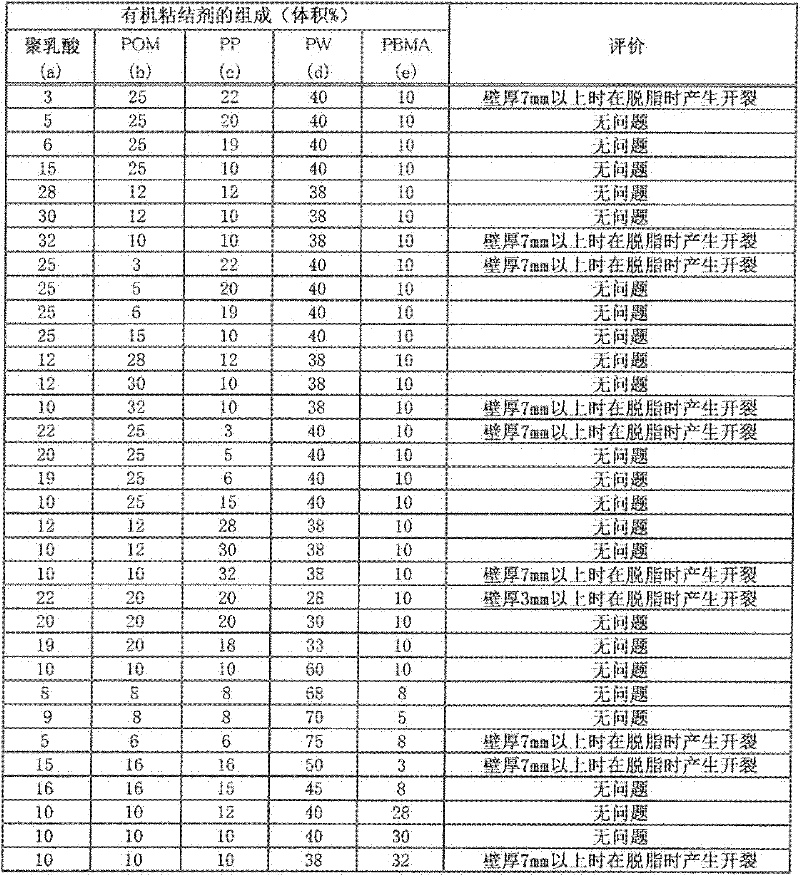

Image

Examples

Embodiment 1

[0029] In the pressurized kneader, first, put polylactic acid, polyoxymethylene and polypropylene, and after melting at 180°C, put in SUS316L powder (average particle size: 10μm), paraffin wax (melting point 63°C), polypropylene wax and methyl Glycidyl acrylate was kneaded for 40 minutes, and the kneaded product was taken out and pulverized to obtain a molding composition. Next, injection was performed at a molding temperature of 150° C. to obtain a molded body having a thickness of 3 mm, a width of 10 mm, and a length of 60 mm.

[0030] Molding composition

[0031] SUS316L powder 100 parts by weight (58 volume%)

[0032] Total binder amount 7.8 parts by weight (42 volume %)

[0033] Binder composition

[0034] (a) Polylactic acid 15.0% by volume

[0035] (b) Polyoxymethylene 10.0% by volume

[0036] (Vicat softening point is 157°C)

[0037] (c) Polypropylene 15.0% by volume

[0038] (Vicat softening point is 137°C)

[0039] (d) Paraffin 40.0% by volume

[0040] (V...

Embodiment 2

[0046] In the pressurized kneader, first, put polylactic acid, polyoxymethylene and polypropylene, and after melting at 180°C, put in SUS304 powder (average particle size: 12μm), paraffin wax (melting point 46°C), carnauba wax and polyformaldehyde Butyl acrylate was kneaded for 40 minutes, and the kneaded product was taken out and pulverized to obtain a molding composition. Next, injection was performed at a molding temperature of 170° C. to obtain a molded body having a thickness of 3 mm, a width of 10 mm, and a length of 60 mm.

[0047] Molding composition

[0048] SUS304 powder 100 parts by weight (60 volume%)

[0049] Total binder amount 7.8 parts by weight (40 volume %)

[0050] Binder composition

[0051] (a) Polylactic acid 15.0% by volume

[0052] (b) Polyoxymethylene 15.0% by volume

[0053] (Vicat softening point is 157°C)

[0054] (c) Polypropylene 10.0% by volume

[0055] (Vicat softening point is 137°C)

[0056] (d) Paraffin 40.0% by volume

[0057] (V...

Embodiment 3

[0063] In the pressurized kneader, first, put polylactic acid, polyoxymethylene and polypropylene at 180 ° C, and after melting, put iron-nickel 8% powder (average particle size: 8 μm), glycidyl methacrylate, paraffin ( melting point of 63° C.) and carnauba wax were kneaded for 40 minutes, and the kneaded product was taken out and pulverized to obtain a molding composition. Next, injection was performed at a molding temperature of 160° C. to obtain a molded body having a thickness of 3 mm, a width of 10 mm, and a length of 60 mm.

[0064] Formed body composition

[0065] Iron-nickel 8% powder 100 parts by weight (55 volume %)

[0066] Total binder amount 7.0 parts by weight (45 volume %)

[0067] Binder composition

[0068] (a) Polylactic acid 15.0% by volume

[0069] (b) Polyoxymethylene 15.0% by volume

[0070] (Vicat softening point is 157°C)

[0071] (c) Polypropylene 15.0% by volume

[0072] (Vicat softening point is 137°C)

[0073] (d) Paraffin 40.0% by volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com