Detection device for detecting sulfur hexafluoride electrical equipment fault gas

A technology for electrical equipment and faulty gas, which is applied in the field of detection devices for detecting faulty gas of sulfur hexafluoride electrical equipment, and can solve the problems of electrochemical instrument zero drift, infrared spectroscopy mutual interference, and component separation that cannot meet the requirements. , to achieve a strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The embodiments of the present invention will be described in detail below in conjunction with the drawings:

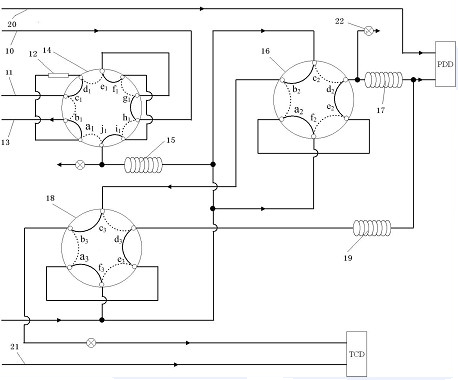

[0076] Such as figure 1 As shown, the detection device for detecting the fault gas of sulfur hexafluoride electrical equipment includes a pulse discharge helium ion detector, a thermal conductivity detector and a separation device. The separation device includes a helium gas inlet pipe 10, a separation unit 1, a separation unit two, and a separation unit 3. The helium gas inlet pipe 1 is connected to the separation unit 1, and the separation unit 1 is respectively connected to the separation unit Two and the separation unit three are connected, the separation unit three is connected with the thermal conductivity detector TCD and the pulse discharge detector PDD, and the separation unit two is connected with the separation unit three. The separation unit 1 includes a sample gas inlet tube 11, a quantitative tube 12, a sample gas outlet tube 13, a ten-port valve 14 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com