Folding-type microchannel porous flat pipe and molding method thereof

A molding method and micro-channel technology, applied in the direction of tubular elements, lighting and heating equipment, heat exchange equipment, etc., can solve the problem that the heat exchange equipment cannot meet the application system well, so as to improve product turnover efficiency and reduce inventory , good effect of pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

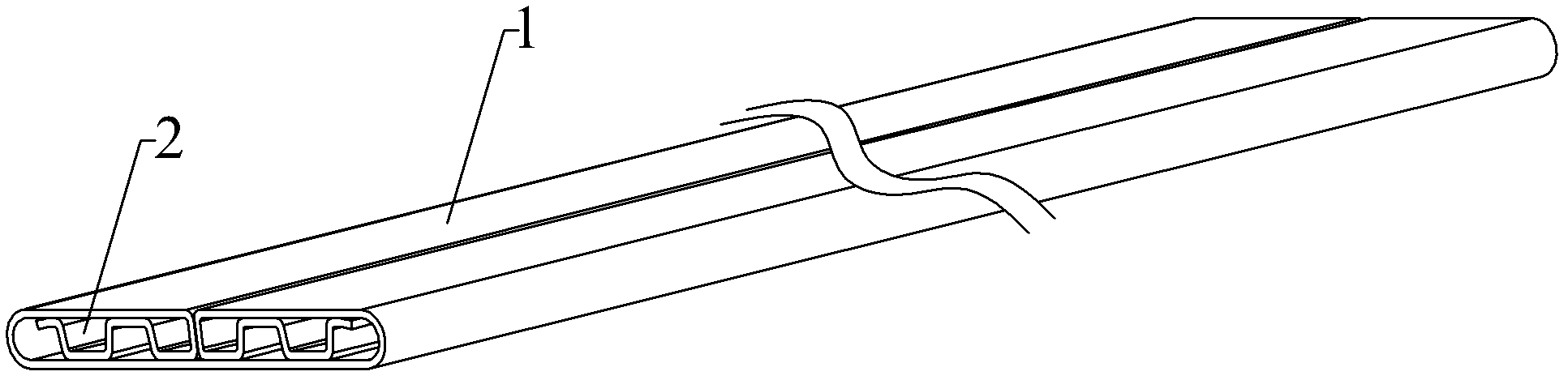

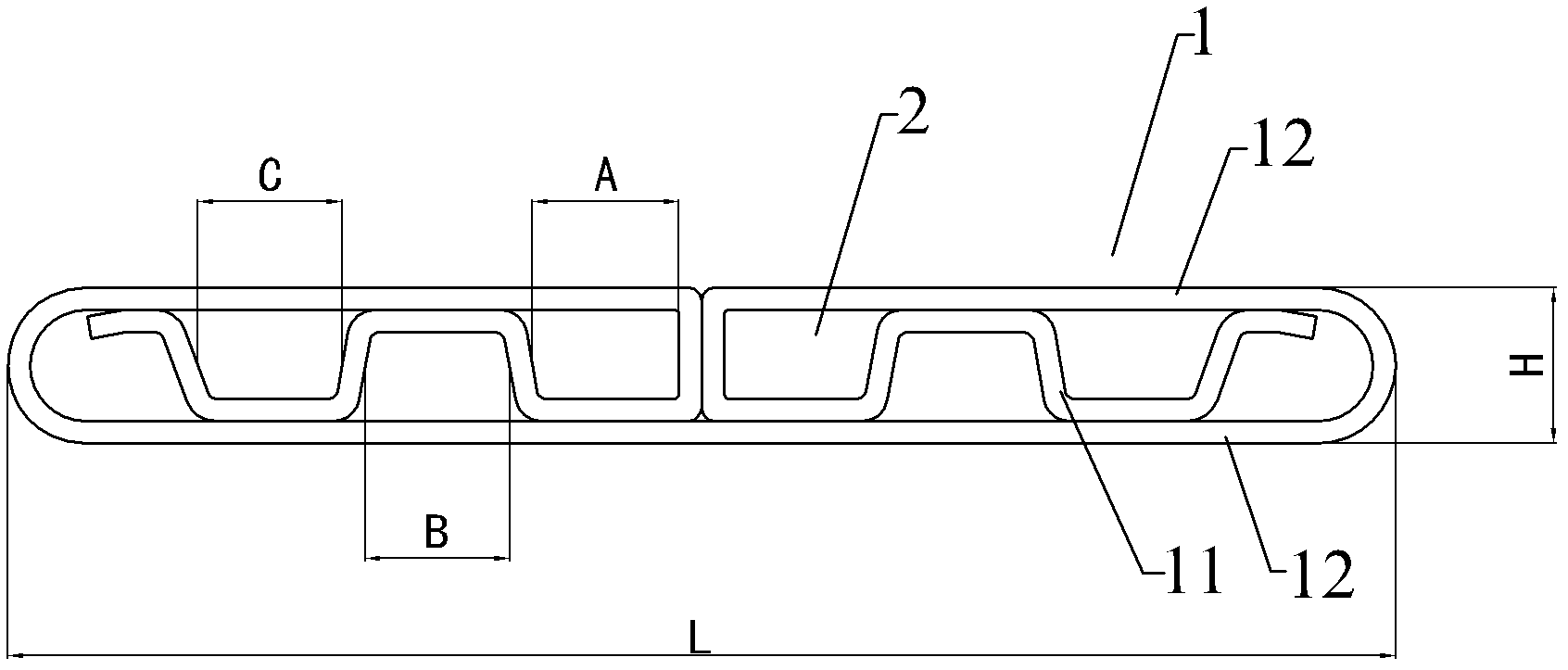

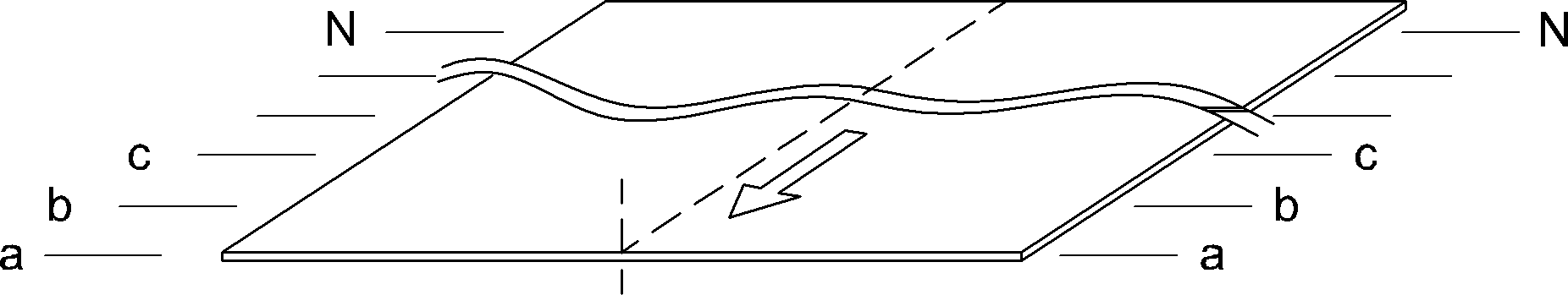

[0026] Such as figure 1 , 2 As shown, the foldable microchannel porous flat tube of the present invention is integrally formed by folding the two ends of a single thin plate 1 through several roundabouts, and its cross-section is flat oval, including several roundabouts. The pores 2 formed by folding and spaced apart from each other.

[0027] The above-mentioned single sheet 1 is made of aluminum platinum plate, which is divided into a roundabout bending part 11 and an embedding part 12. The flat tube pores 2 are bent and folded by the roundabout bending part 11 of the single sheet 1 and then folded and folded with the single sheet 1 The embedding portion 12 is welded and fixed, and the upper and lower planes of the detour bending portion 11 are respectively seamlessly brazed and hermetically connected to the plane of the embedding portion 12. The tortuous bending portion 11 forms a partition plate between the flat tube pores 2 to enhance the plane compressive strength of the por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com