Preparation method for paper nanometer level surface sizing agents capable of realizing fast curing

A surface sizing agent, nano-scale technology, applied in the direction of water repellent addition, etc., can solve the problems of paper surface strength and smoothness decrease, aggravate hair loss and powder loss, etc., to improve surface strength, improve sizing effect, Promotes fast binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

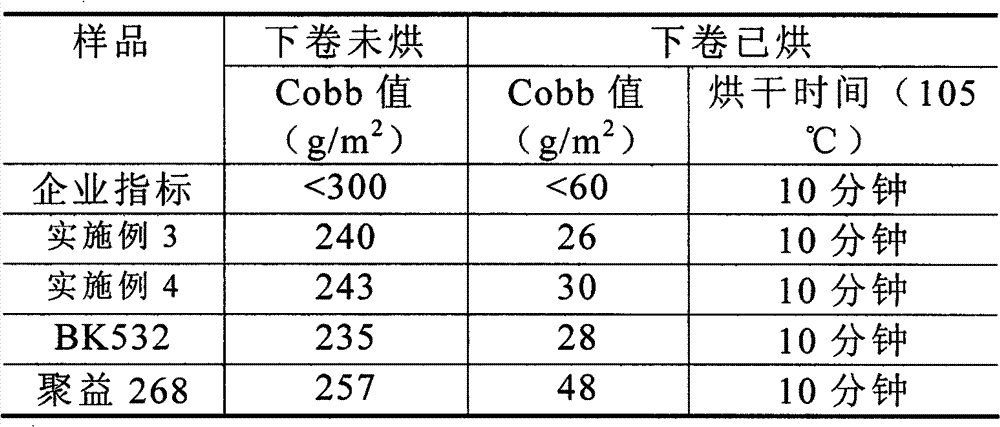

Examples

preparation example Construction

[0048] The preparation method of the paper nano-scale surface sizing agent that can be ripened rapidly comprises the following steps:

[0049] A, raw materials: cationic polymer emulsifier based on 20-60% of total weight; (methyl) styrene monomer based on 2-18% of total weight; (meth)acrylic acid based on 2-18% of total weight Ester monomer; 0-5% internal crosslinking monomer based on total weight; 0.5-5% pH regulator based on total weight; 0-3% molecular weight regulator based on total weight; 0.01-1% based on total weight % reduction initiator; 0.1-5% oxidation initiator based on total weight; 10-80% water based on total weight; optimal weight of water is 30-73% based on total weight.

[0050] B. Preparation:

[0051] ① Mix (methyl) styrene monomer, (meth) acrylate monomer, molecular weight regulator and internal crosslinking monomer evenly to form a mixed monomer; ② Mix cationic polymer emulsifier, water, Mix the pH adjuster, molecular weight adjuster and reduction initiato...

Embodiment 1

[0058] Add 40g of styrene, 10g of butyl acrylate, 30g of dimethylaminoethyl methacrylate, 80g of isopropanol and 120g of water into a 500ml four-necked flask equipped with a condenser, a stirrer and a thermometer. Stir, raise the temperature to 70°C, slowly add 20g of 5wt% ammonium persulfate aqueous solution dropwise, and finish adding in about 30 minutes. After the dropwise addition was completed, the temperature was gradually raised to 85° C., and the reaction was carried out for 4 hours. Then, cool to 45°C, add 8g of epichlorohydrin, keep the temperature constant, and react for 40min. During the reaction, the viscosity will increase. Then, quickly add 10g of concentrated hydrochloric acid and 80g of water, and continue stirring for 10min. Cool and discharge to obtain a cationic polymer emulsifier with a solid content of 20% and a pH of 3.43.

[0059] In a 500ml four-neck flask equipped with a condenser, dropping device, stirrer and thermometer, add 120g cationic polymer...

Embodiment 2

[0061] In the present embodiment, in the 500ml four-necked flask that has condenser, dropping device, agitator and thermometer, add 160g cationic polymer emulsifier, 10g styrene, 3g tert-butyl acrylate, 4.5g glacial acetic acid, 0.05g sodium bisulfite, 0.1g dodecanethiol and 106g water. Stir, heat up to 70°C, add 4g of 5wt% sodium persulfate solution, and stir for 10 minutes. Then, at this temperature, the monomer mixture (30g styrene, 37g ethyl acrylate) and 16g 5wt% sodium persulfate solution were added dropwise at the same time, and the dropping time was controlled at about 1.5h. Then, the temperature was raised to 80° C., and the reaction was carried out for 3 h. After cooling and discharging, the paper nano-scale surface sizing agent that can be rapidly matured is obtained, the solid content is 30%, and the pH is 3.43. The rest are similar to the implementation example 1, and will not be repeated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com