Negative pressure ammonia distillation process and device for residual ammonia water in coking production

A technology for steaming ammonia and ammonia water under negative pressure is applied in the field of auxiliary processes, which can solve the problems of increased waste water, high energy consumption, and undiscovered problems, and achieves the effects of convenient renovation and installation, convenient adjustment, and stable indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

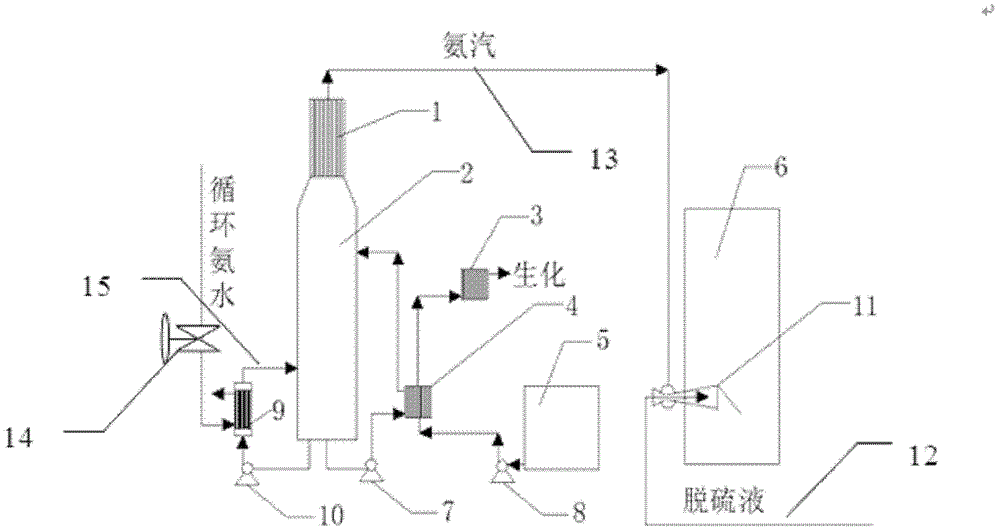

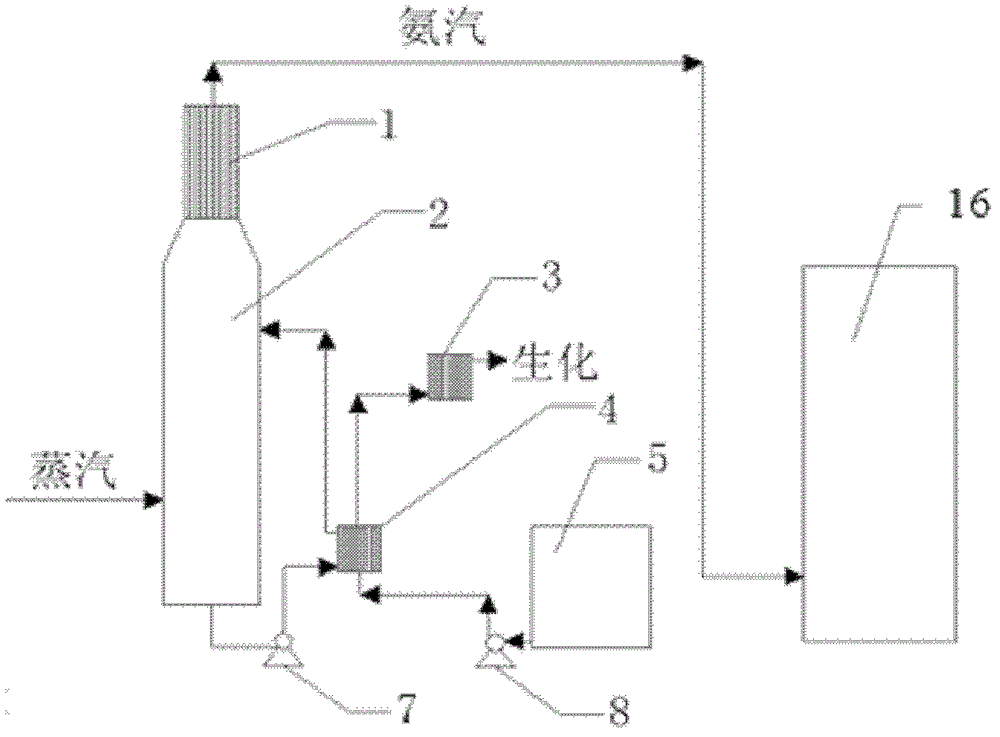

[0020] Embodiment 1: a kind of residual ammonia water negative pressure ammonia distilling device, structure such as figure 1 As shown, it includes ammonia vapor splitter 1, ammonia distillation tower 2, ammonia distillation wastewater cooler 3, ammonia distillation wastewater / residual ammonia water heat exchanger 4, residual ammonia water tank 5, desulfurization tower 6, ammonia distillation wastewater pump 7, remaining Ammonia water pump 8, the ammonia vapor splitter 1 at the top of the ammonia distillation tower 2 is connected to the ammonia vapor pipeline 13, and the bottom of the ammonia distillation tower 2 is sequentially connected to the ammonia distillation wastewater pump 7, the ammonia distillation wastewater / residual ammonia water heat exchanger 4 and the ammonia distillation Wastewater cooler 3, biochemical treatment system; remaining ammonia water tank 5 is connected to remaining ammonia water pump 8, ammonia distillation waste water / residual ammonia water heat e...

Embodiment 2

[0022] A kind of coking production residual ammonia negative pressure ammonia distilling process, used device is as described in embodiment 1; When using:

[0023] First open the ammonia distillation wastewater / circulation ammonia water heat exchanger 9 and the ammonia distillation wastewater circulation pump 10, so that the heat of the circulating ammonia water is brought into the ammonia distillation tower 2 by the ammonia distillation wastewater through the heat exchanger 9, and the circulation ammonia flow regulating valve 14 is adjusted to The circulating ammonia flow is adjusted to 120m 3 / h or so, adjust the temperature at the top of ammonia distillation tower 2 to 60-80°C, open the valve of the desulfurization liquid pipeline entering Venturi tube 11 and adjust the flow rate to 150m 3 About / h, the desulfurization liquid enters the desulfurization tower 6 at a high speed to form a suction effect, adjust the pressure at the top of the ammonia distillation tower 2 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com