System and technology for recovering sodium nitrate from tin-containing waste liquid treatment tail water

The technology of a waste liquid treatment and recovery system is applied in the recovery system and recovery process field of recovering sodium nitrate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

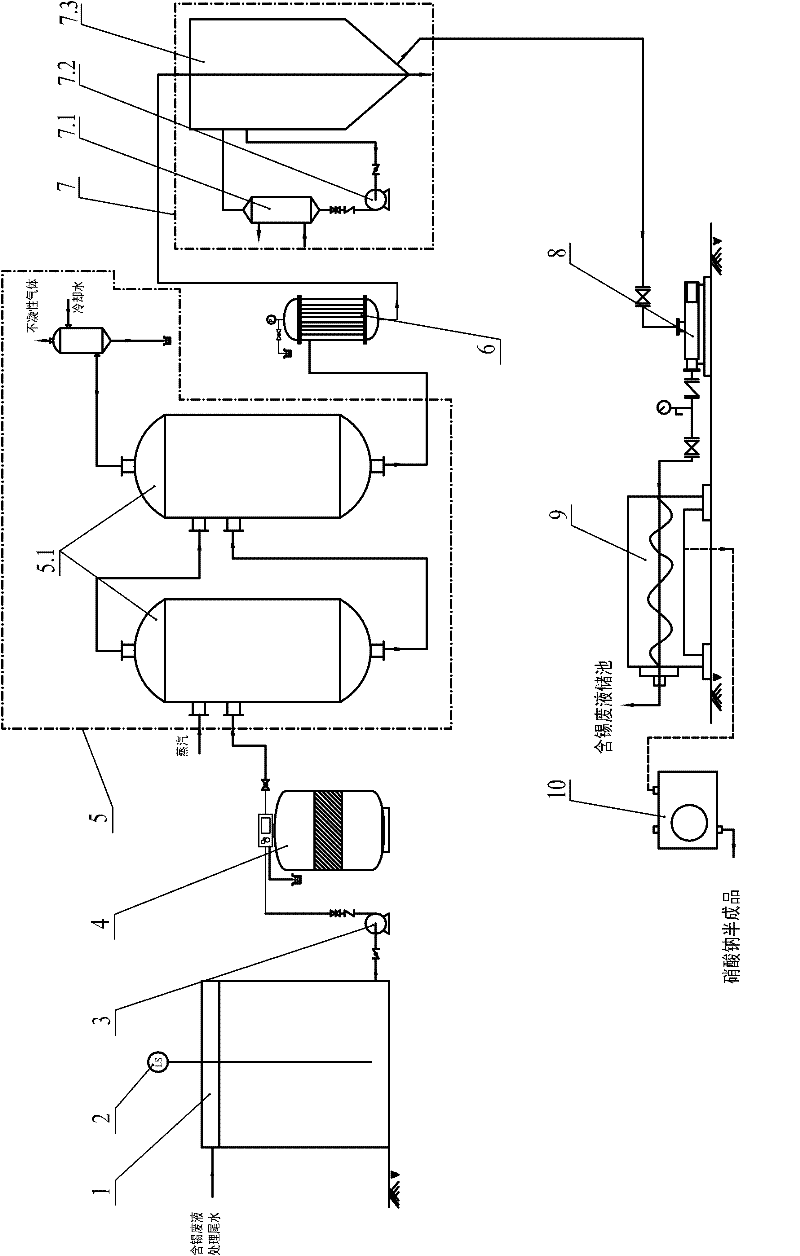

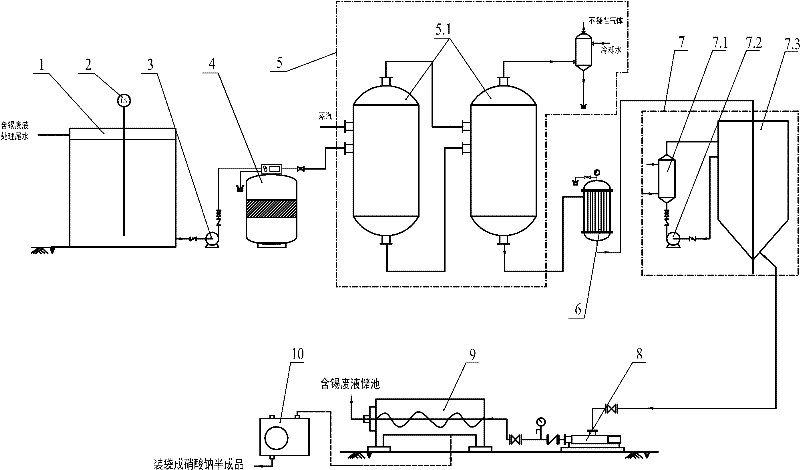

Image

Examples

Embodiment 1

[0043] Tin-containing waste liquid treatment tail water 30T / d, in which NaNO 3 The content is 18.6%, and the pH value is 7.5.

[0044] The recycling process steps are as follows:

[0045] (1), the tin-containing waste liquid treatment tail water is collected and stored in the waste water storage tank 1, and left to stand for a period of time to achieve uniform quality and quantity;

[0046] (2), through the lifting pump (3) in the liquid level automatic control system, the tin-containing waste liquid treatment tail water in the waste water storage tank 1 is transported to the purification and refining device 4 for purification and purification, and the fine filter with a filtration accuracy of 5 μm Screen filter to remove sludge, colloid, organic matter and other particles in the tail water of tin-containing waste liquid treatment, with a specific surface area of 900-1100m 2 / g of coconut shell activated carbon adsorption filter material to absorb the peculiar smell in the...

Embodiment 2

[0052] Tin-containing waste liquid treatment tail water 55T / d, in which NaNO 3 The content is 21.5%, and the pH value is 6.5.

[0053] The recycling process steps are as follows:

[0054] (1), the tin-containing waste liquid treatment tail water is collected and stored in the waste water storage tank 1, and left to stand for a period of time to achieve uniform quality and quantity;

[0055] (2), through the lifting pump (3) in the liquid level automatic control system, the tin-containing waste liquid treatment tail water in the waste water storage tank 1 is transported to the purification and refining device 4 for purification and purification, and the fine filter with a filtration accuracy of 10 μm Screen filter to remove sludge, colloid, organic matter and other particles in the tail water of tin-containing waste liquid treatment, with a specific surface area of 900-1100m 2 / g of coconut shell activated carbon adsorption filter material to absorb the peculiar smell in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com