Inking roller clutch device

A technology of clutch device and ink roller, which is applied in the direction of printing, printing machines, general parts of printing machinery, etc., can solve the problems of unstable performance, high cost, complex structure, etc., and achieve the effect of reliable performance, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

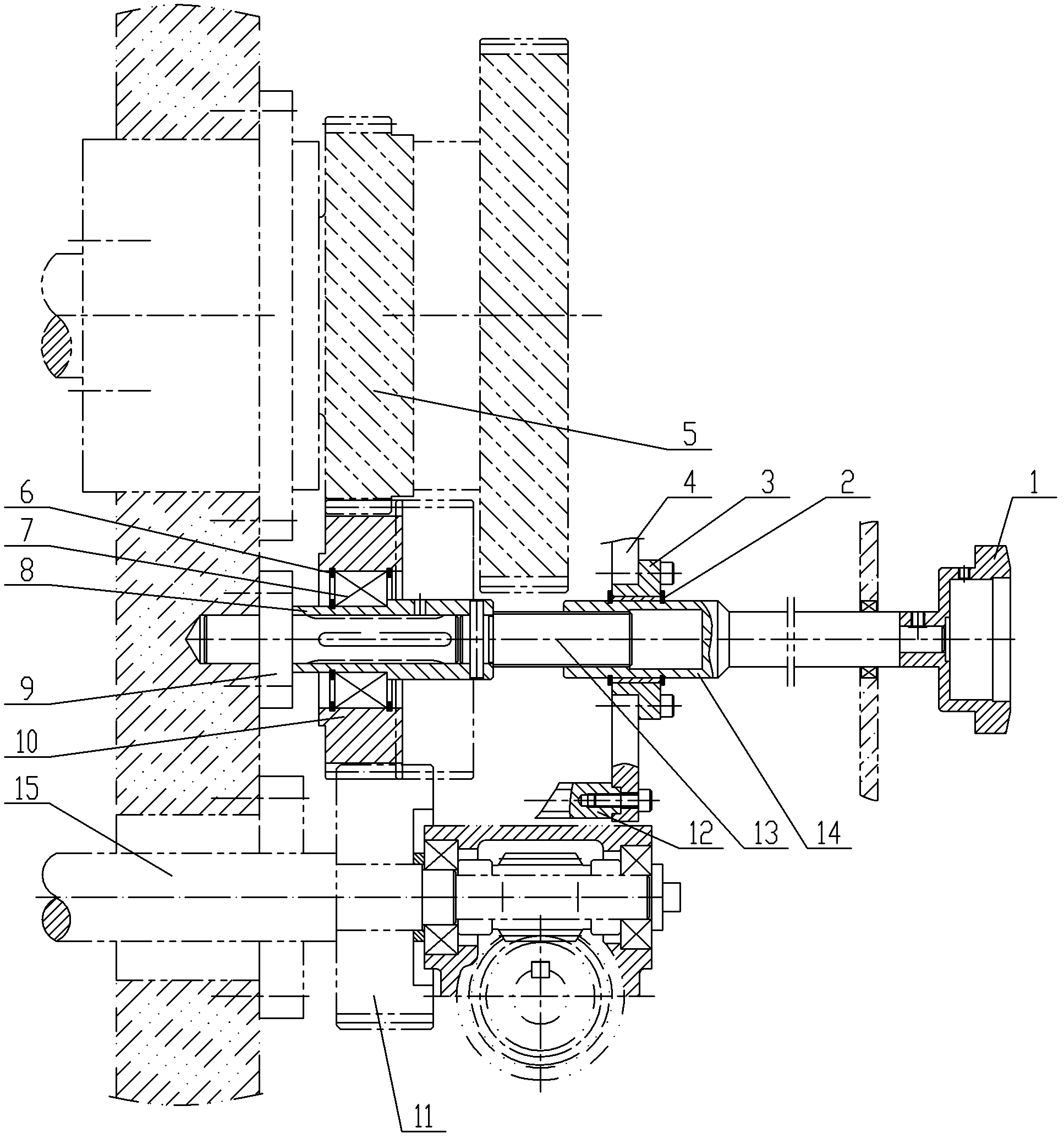

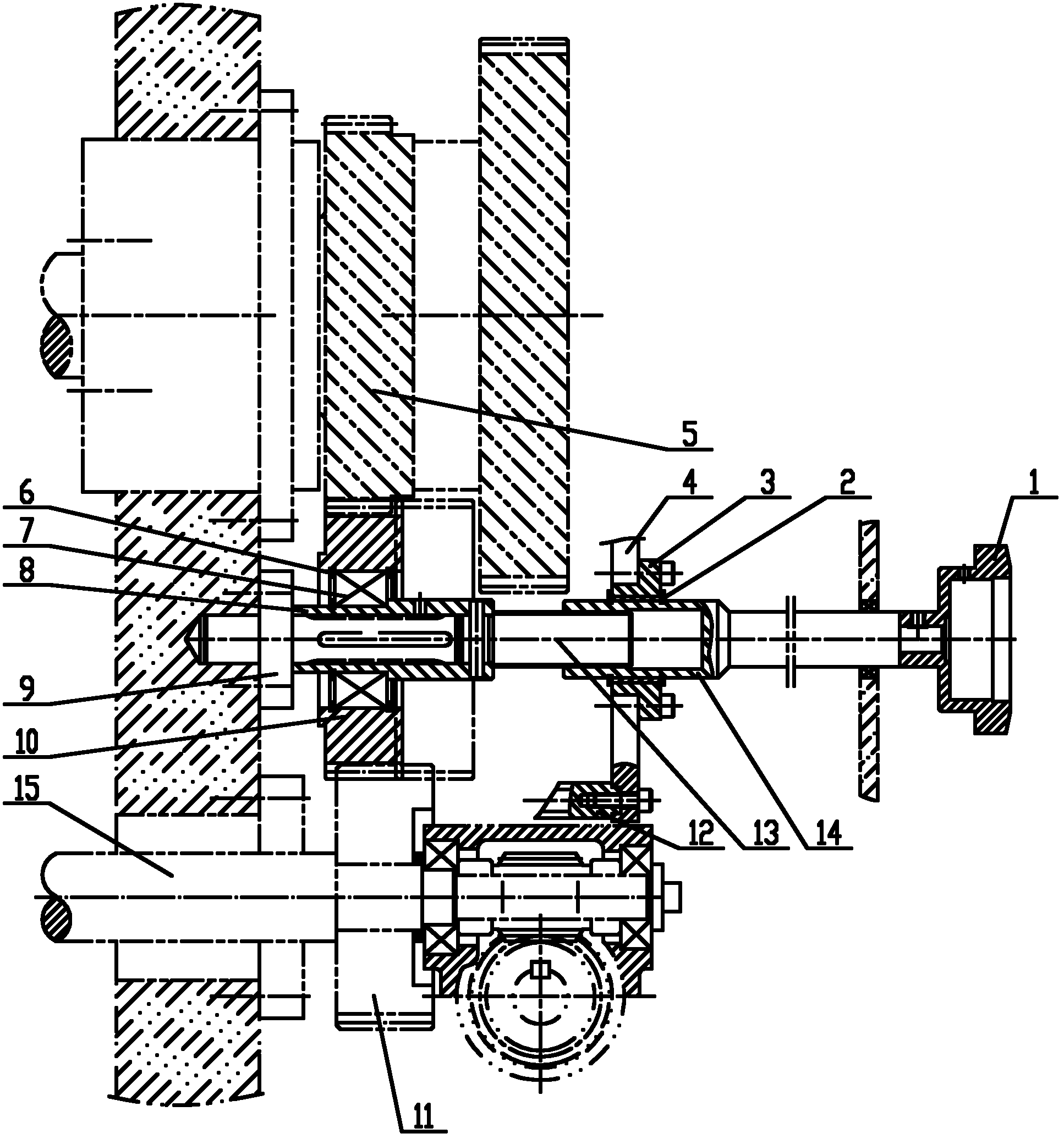

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] figure 1 Including hand wheel 1, oil seal 2, nut seat 3, support plate 4, plate roller gear 5, retaining ring 6, bearing 7, bearing seat 8, shaft 9, clutch gear 10, ink roller gear 11, and support rod 12 , Screw rod 13, nut 14, string ink roller 15 etc.

[0014] like figure 1 As shown, the present invention is an ink roller clutch device, which is arranged between the axis-parallel version roller gear 5 and the ink roller gear 11, and the ink roller gear 11 is installed on the ink roller 15. The present invention includes a clutch gear 10 that meshes with both the printing roller gear 5 and the stringer roller gear 11 . The clutch gear 10 is rotatably installed on the bearing seat 8 through the bearing 7, and the bearing seat 8 is slidably fitted on the shaft 9 through the spline fit, and the shaft 9 is installed on the wallboard o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com