Four-roller direct-driving type diamond wire numerical control slicer

A technology of diamond wire and slicing machine, applied in stone processing equipment, working accessories, fine working devices, etc., can solve the problems of large space occupied by motors and transmission mechanisms, increasing uncertain factors, and affecting slicing processing, etc. The effect of small space, low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

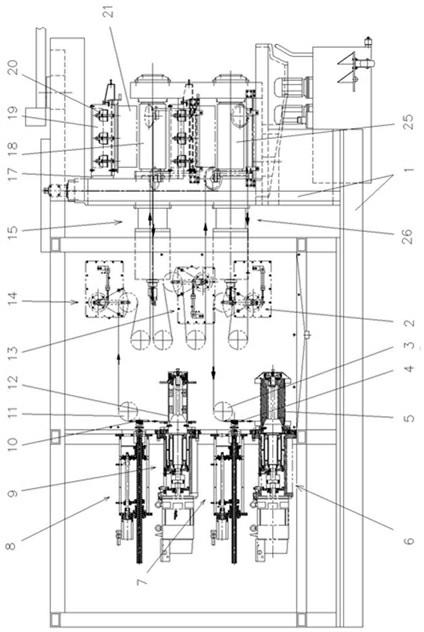

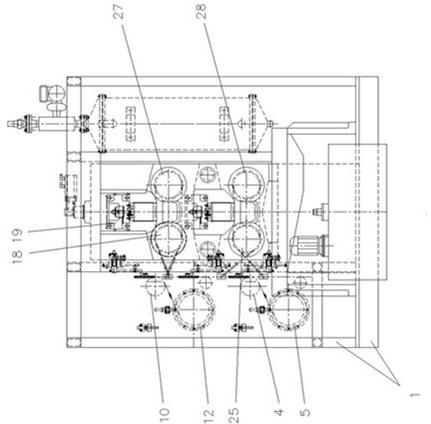

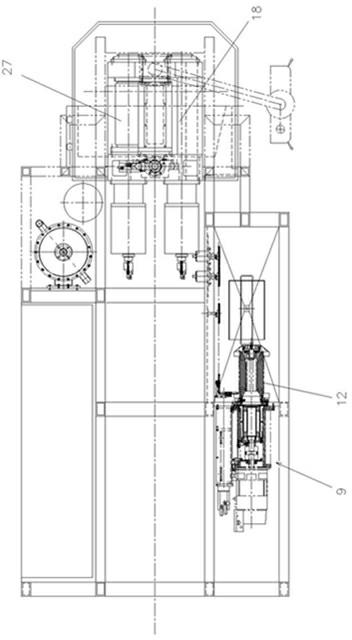

[0023] Such as figure 1 , 2 , shown in 3: 1 is a frame, and frame 1 adopts section steel welding to manufacture, and four groups of cutting roller mechanisms that the axes of upper, lower, left and right distributions are arranged parallel to each other are installed on frame 1, and 15 is upper left cutting Roller mechanism, 26 is the lower left cutting roller mechanism. The right part of upper left cutting roller mechanism 15 is equipped with upper left cutting roller 18, and the right part of lower left cutting roller mechanism 26 is equipped with lower left cutting roller 25. The upper right cutting roller 27 is equipped with on the right part of the upper cutting roller mechanism on the right side, and the lower right cutting roller 28 is equipped with on the right part of the lower cutting roller mechanism.

[0024] The upper take-up and pay-off mechanism 9 and the last take-up and pay-off follow-up mechanism 8 are installed on the frame 1, and the upper take-up and tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com