Screw locking machine

A locking machine and locking mechanism technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of reduced processing efficiency, damage to locked products, and excessive size, so as to improve processing efficiency and accuracy and convenience, reduce damage rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention provides a screw locking machine. In order to make the purpose, technical solution and advantages of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

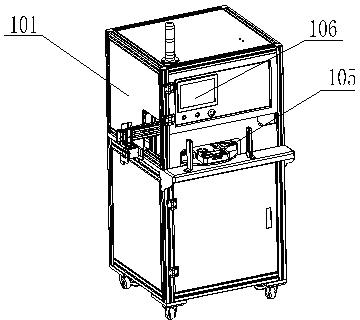

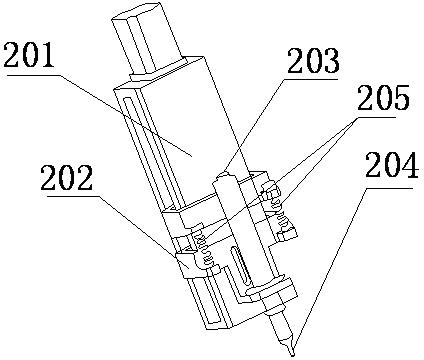

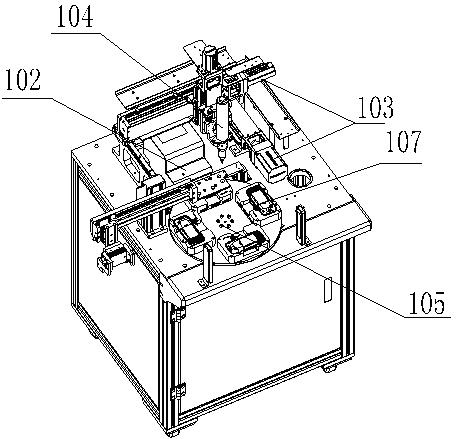

[0024] The invention provides a screw locking machine, through the cooperation and linkage of the feeding mechanism, the three-axis positioning mechanism, the locking mechanism and the product positioning mechanism, the products with locking can be processed continuously, and the processing efficiency of the screw locking machine is improved. The damage rate of products to be locked and paid is reduced. Such as figure 1 and image 3 The screw locking machine shown comprises a frame 101 which may take any technical form known in the art. The frame 101 is provided with a feeding mechanism 102, a three-axis positioning mechanism 103, a locking mechanism 104 and a product positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com