A support platform for splicing large flanges

A technology for supporting platforms and large flanges, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that the supporting platform cannot facilitate flange splicing, and the roundness and flatness of flanges exceed the allowable Tolerance range and other issues to achieve the effect of preventing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

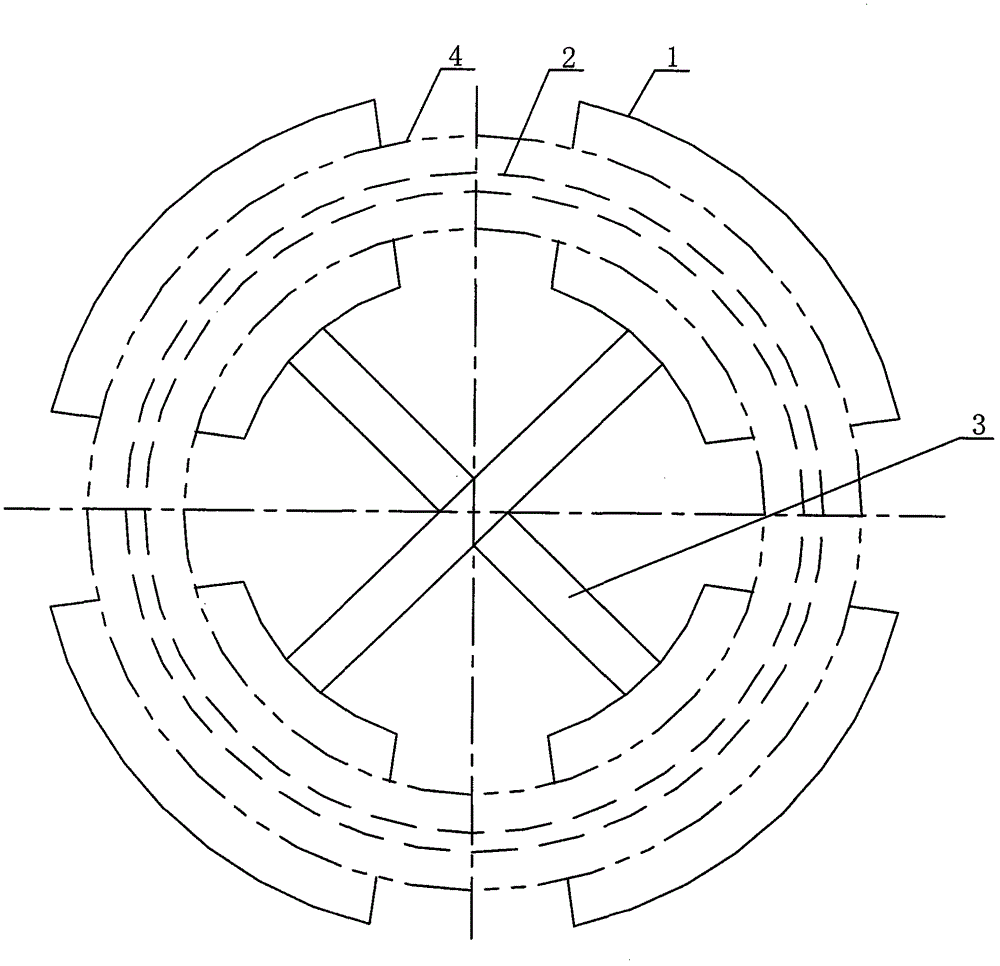

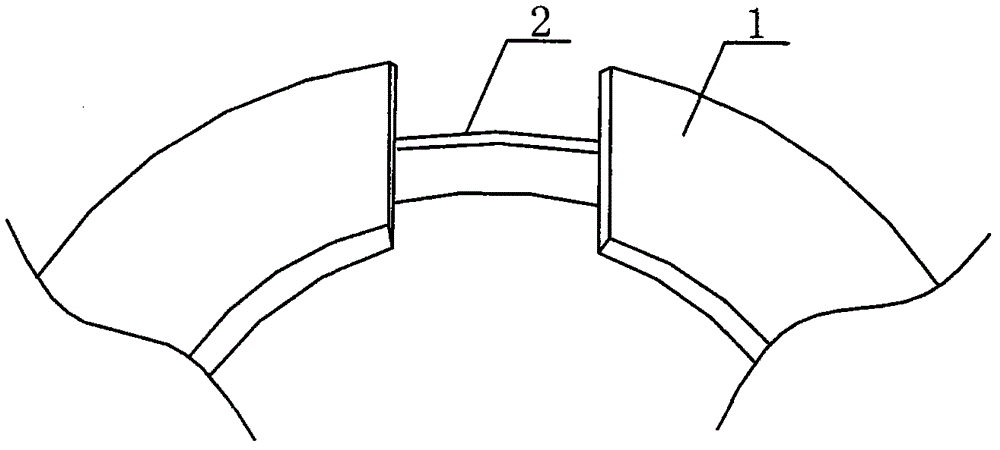

[0013] Such as Figure 1~2 In the shown embodiment, a large-scale flange splicing support platform according to the present invention includes reinforcing ribs 2 and four arc plates 1, and the arc plates 1 have a thickness of 30 mm and a width of the difference between the inner and outer diameters of the flanges. It is made of a flat plate with a diameter of 100 mm, and the reinforcing rib 2 is made of a flat plate with a thickness of 10 mm and a width of 150 mm, and the reinforcing rib 2 is made into a circle, and four circular arc plates 1 are evenly welded on the reinforcing rib 2, and four circular arc plates There are gaps for welding between the plates 1, and the inner side of the four circular arc plates 1 is provided with a cross-shaped fixed support 3. When working, find out the center of the support platform, use the center of the circle to calibrate the horizontal plane of the support platform, and finally place it on the platform surface. Draw the reference line o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com