Impact type microreactor

A micro-reactor, reaction plate technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., to achieve the effects of sufficient reaction, not easy to block, and easy to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be further described in detail below.

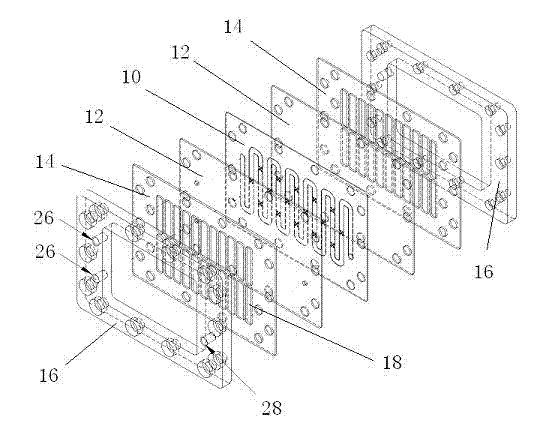

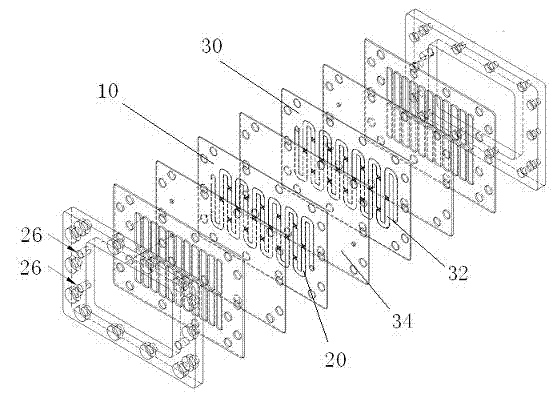

[0028] Such as figure 1 , Figure 4 , Figure 5 , Figure 7 and Figure 8 As shown, the first embodiment of an impact-type microreactor of the present invention includes a reaction plate 10, and a cover plate 12, a pressure plate 14 and a fixing plate 16 are stacked on both sides of the reaction plate 10 in sequence. The reaction plate 10 and the cover plate 12 are square sheets made of transparent tempered glass; the surfaces in contact with each other are polished through a polishing process to ensure that they are tightly bonded to each other and achieve a good seal. Pressing plate 14 is the square sheet that stainless steel is made, offers the observation window 18 of several square through-hole shapes on it. The fixing plate 16 is a square frame structure made of aluminum alloy. The fixing plate 16, the pressing plate 14, the cover plate 12 and the reaction plate 10 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com