Reaction plate of microreactor of eccentric circle structure

A technology of microreactor and reaction plate, which is applied in chemical instruments and methods, chemical/physical/physicochemical processes, chemical/physical processes, etc., can solve problems such as insufficient mixing, crushing of reactants, etc., to achieve full reaction, Ease of production and processing, low fluid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

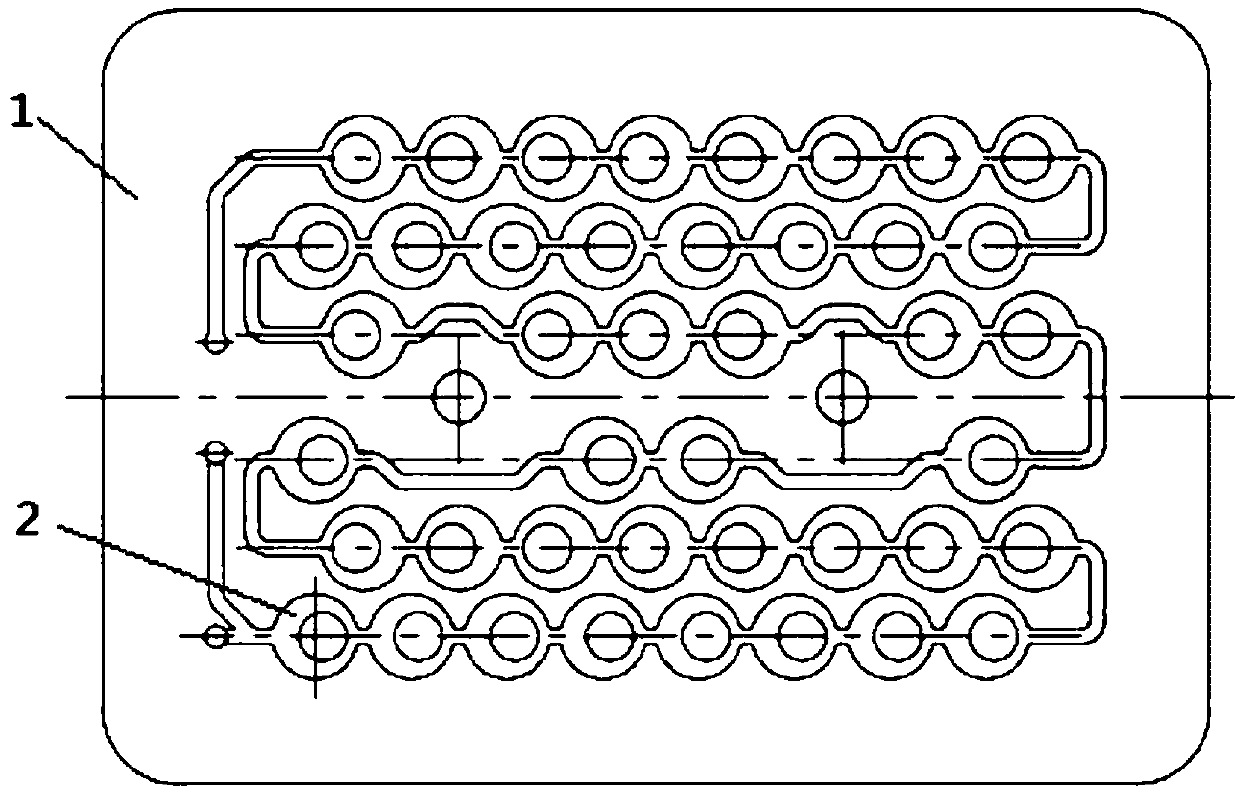

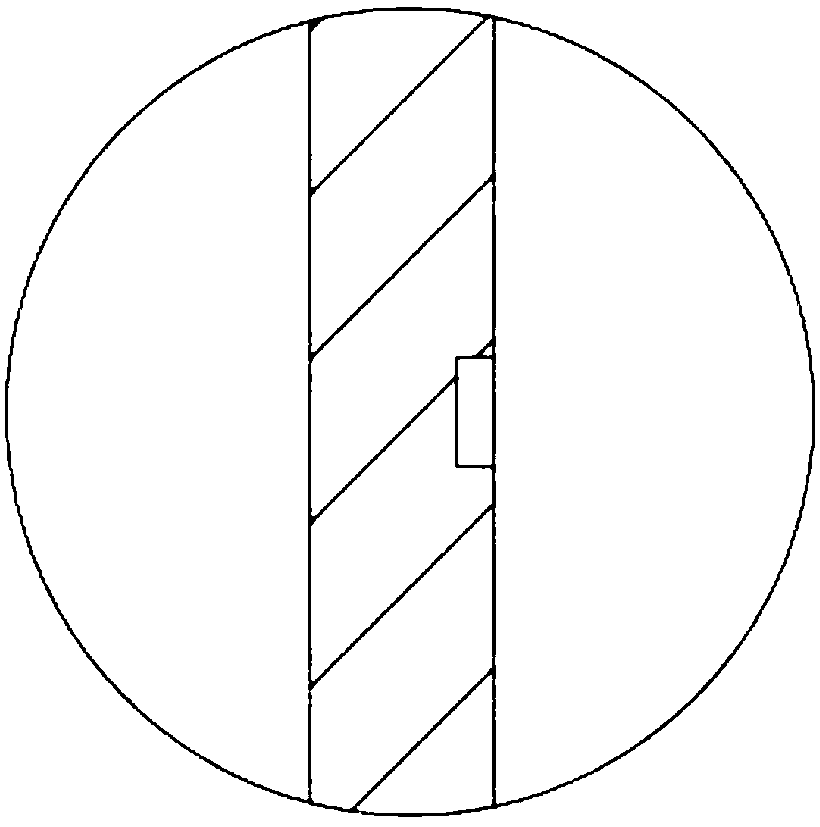

[0022] In order to achieve the purpose of the present invention, as Figure 1-3 As shown, in one of the embodiments of the present invention, a microreactor reaction plate with an eccentric circular structure is provided, including a reaction plate body 1, and a capillary microchannel 2 arranged on the reaction plate body 1, and a capillary microchannel 2 It is arranged in six rows and forms three continuous S shapes. The capillary micro-channels include 42 micro-reaction chambers and channels connecting the micro-reaction chambers. The micro-reaction chambers are in an eccentric circular structure. Connected end to end, the inlet end of the micro-reaction chamber is the big end, and the outlet end of the micro-reaction chamber is the small end.

[0023] Compared with the prior art, this embodiment adopts an eccentric circular structure desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com