Pesticide spraying plant protection machine

A mechanical and plant protection technology, which is applied to the device, application, and animal husbandry of catching or killing insects, and can solve the problems of loud noise, single function, waste of power and energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

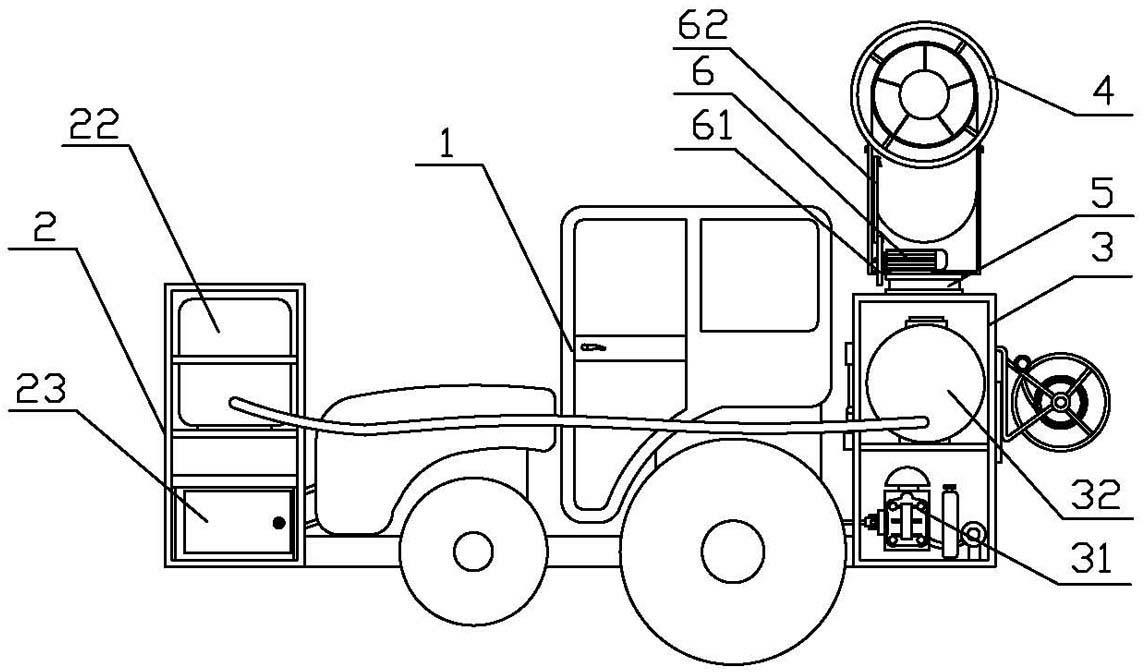

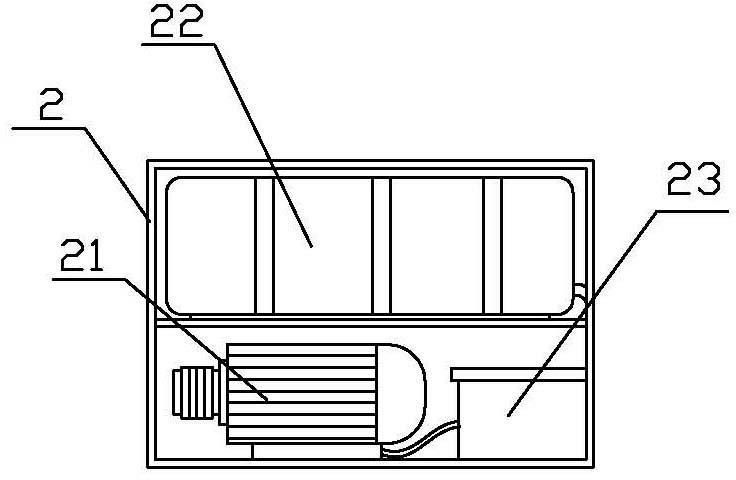

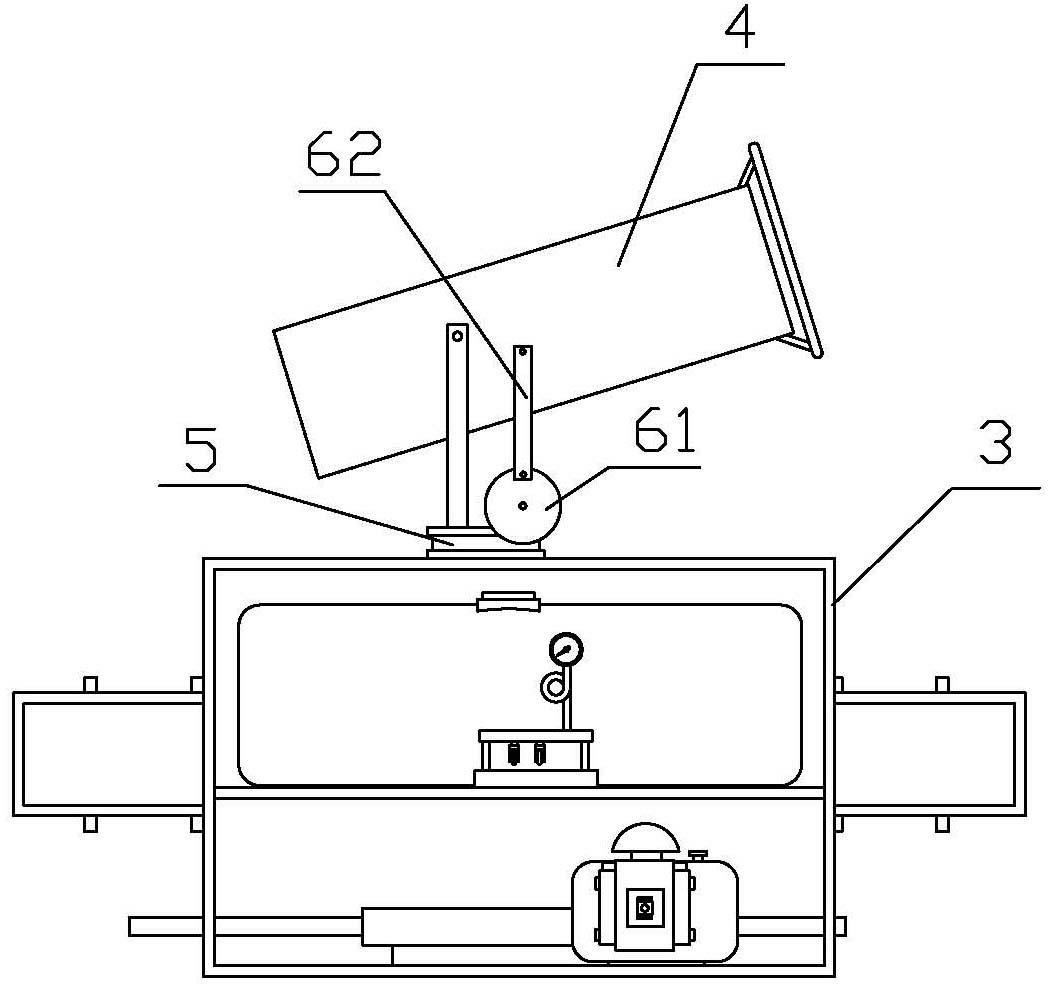

[0015] Such as figure 1 As shown, a kind of pesticide spraying plant protection machinery of the present invention comprises tractor 1, the front support 2 that is installed in tractor 1 front end, the rear support 3 that is installed in tractor 1 rear end, front support 2 and rear support 3 all are square steel, A rectangular frame structure welded by angle iron or channel steel, used to support and install other components. Such as figure 2 As shown, a generator 21 and a counterweight medicine box 22 are installed on the front bracket 2, the generator 21 is connected to the flywheel of the tractor, and the power output terminal of the generator 21 is electrically connected to the distribution box 23, and the distribution box 23 is also installed on the front support 2 and is located on one side of the generator 21; as image 3 , Figure 4 As shown, a diaphragm pump 31 and a main drug box 32 are installed on the rear support 3, the diaphragm pump 31 is connected to the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com