High-power externally-coupled electrodeless UV (ultraviolet) lamp

An out-coupling, high-power technology, applied in the field of high-power out-coupling electrodeless ultraviolet lamps, to achieve the effects of long life, reduced production costs, and reduced irradiation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

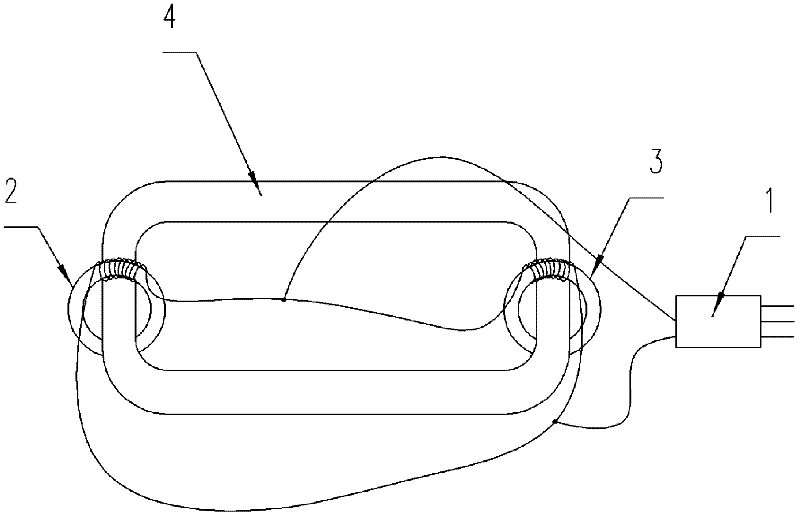

[0022] Embodiment 1: as figure 1 As shown, the high-power externally coupled electrodeless ultraviolet lamp in this embodiment includes a closed lamp tube with a ring-shaped section, a coupler and a high-frequency driver 1, which is characterized in that the high-frequency driver 1 is a high-frequency driver with self-adaptive characteristics, The diameter of the closed lamp tube is 56mm, and the internal volume of the closed lamp tube is 1560cm 3 , the closed lamp tube is filled with inert gas and mercury vapor with a pressure of 0.12 Torr, the amount of mercury filled in the closed lamp tube is 25 mg, and the coupler is composed of a first coupler unit 2 and a second coupler unit 3 , the first coupler unit 2 and the second coupler unit 3 are respectively sleeved on the outer wall of the closed lamp tube, and are respectively located at both ends of the centerline of the closed lamp tube, the first coupler unit 2 and the second coupler unit Units 3 are all closed magnetic ri...

Embodiment 2

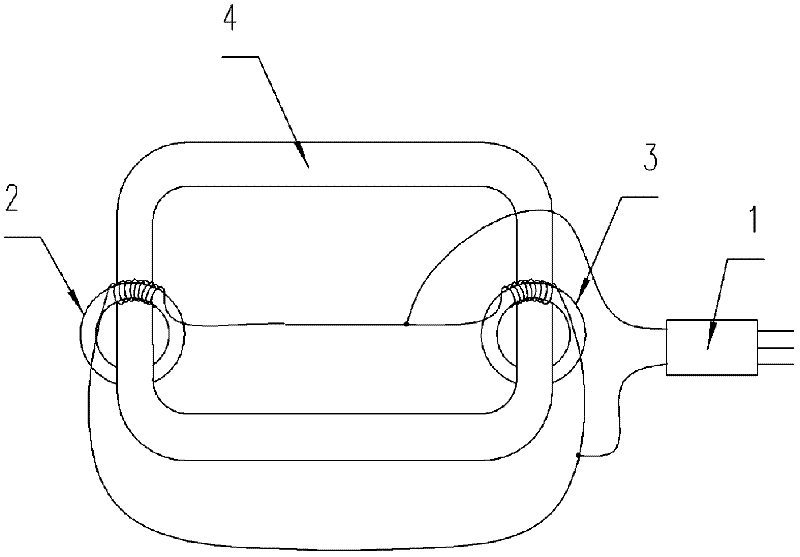

[0024] Embodiment 2: as figure 2 As shown, this embodiment is similar to Embodiment 1, and the difference is that the closed lamp tube in this embodiment is a rectangular closed lamp tube 4, the length of the rectangular closed lamp tube is 270 mm, and the width is 140 mm. 4 The outer diameter is 46 mm, and the inner volume of the rectangular closed lamp tube 4 is 860 cm 3 , the rectangular closed lamp tube 4 is filled with 0.16 Torr argon gas, the amount of mercury filled is 18mg, and the high frequency driver 1 is a 100W high frequency driver. The electric power is 104W, and the ultraviolet irradiance is 280μW / cm at 1 meter 2 .

Embodiment 3

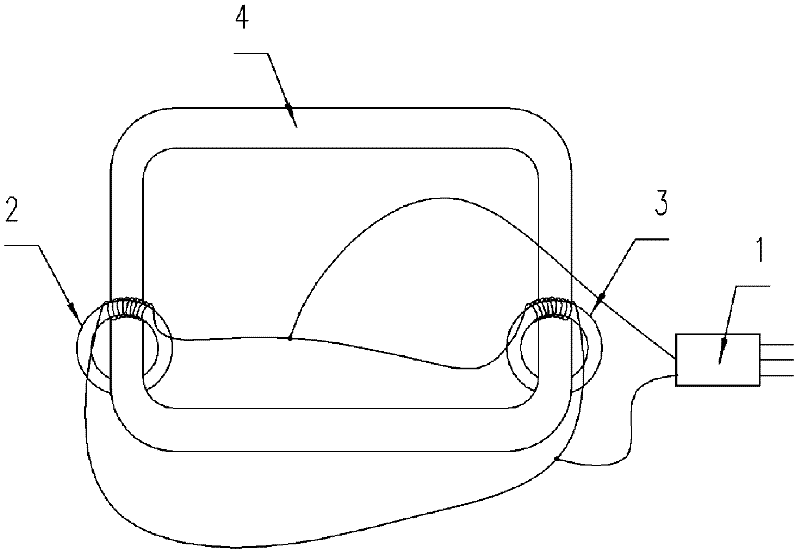

[0025] Embodiment 3: as image 3 As shown, this embodiment is similar to Embodiment 1, the difference is that the closed lamp tube in this embodiment is a rectangular closed lamp tube 4, and the rectangular closed lamp tube 4 is 440 mm long and 160 mm wide. The outer diameter of the tube 4 is 56 mm, and the inner volume of the rectangular closed lamp tube 4 is 2100 cm 3 , the rectangular closed lamp tube 4 is filled with 0.09 Torr argon gas, the amount of mercury filled is 35mg, and the high frequency driver 1 is a 220W high frequency driver. The electric power is 217W, and the ultraviolet irradiance is 900μW / cm at 1 meter 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com