Automatic magnetic particle testing unit for toe cracks at inner wall of straight welded pipe

A welding toe crack and magnetic particle detection technology, which is applied in the direction of material magnetic variables, optical test flaws/defects, etc., can solve the problems that cannot meet the needs of automatic production and batch testing of welded pipes, lack of real-time monitoring of test results, inaccurate positioning of test records, etc. problem, the detection results can be saved in real time, the operating rate of the grinding machine can be improved, and the automatic detection speed can be adjusted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

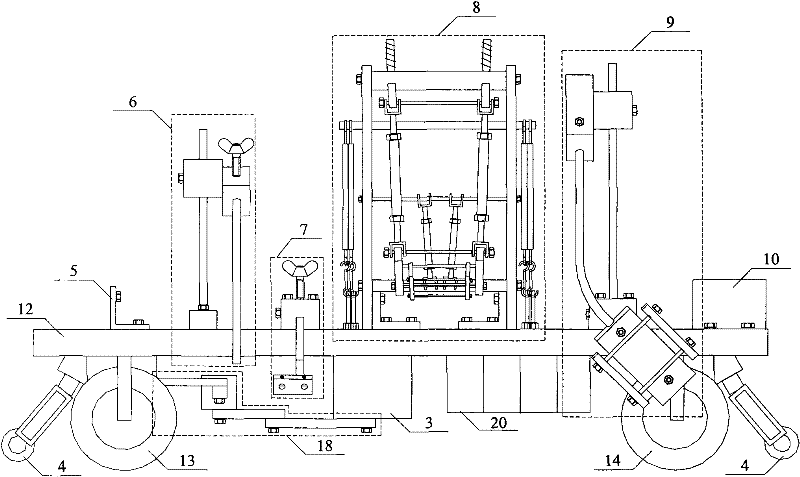

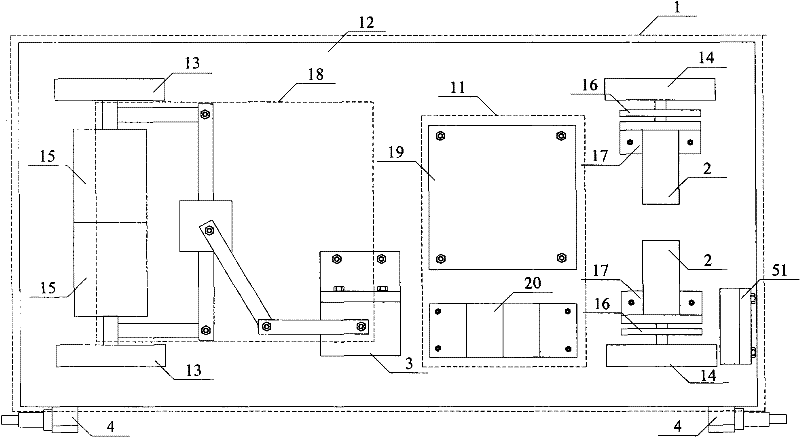

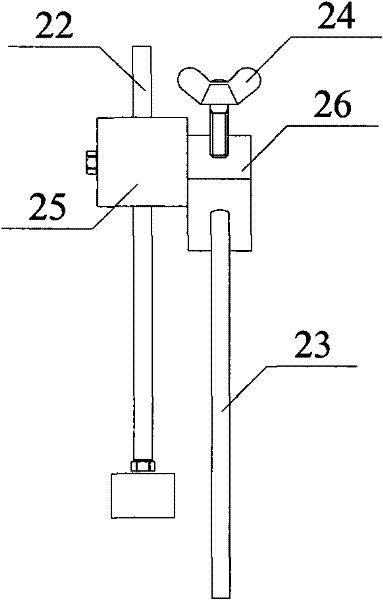

[0041] like figure 1 As shown, this embodiment includes: car body 1, drive motor 2, steering gear 3, travel switch 4, transformer support 5, camera support 6, sprinkler support 7, cross yoke support 8, ultraviolet lamp support 9, water pump Water tank support 10, control part 11, wherein: car body 1 comprises car plate 12, universal wheel 13, drive wheel 14, stopper 15, supporting plate 16, rotating support 17, guide bar part 18, two stoppers 15 upper ends It is parallel and fixedly connected with both sides of the bottom front end of the vehicle plate 12, the guide rod part 18 is coaxially connected with the two universal wheels 13 through the block 15, and the output end of the steering gear 3 passes between the guide rod part 18 and the two universal wheels 13. The shafts between them are fixedly connected, the upper ends of the two rotating supports 17 are fixedly connected in parallel with both sides of the rear end of the bottom of the car plate 12, the lower ends are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com