Additive for improving resisting phase separation performance and heat value of methanol gasoline

A methanol gasoline and additive technology, applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of inability to use and store and transport calorific value, increased fuel consumption of methanol gasoline, and easy occurrence of air resistance, etc. Water resists phase separation, reduces fuel consumption, and reduces mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

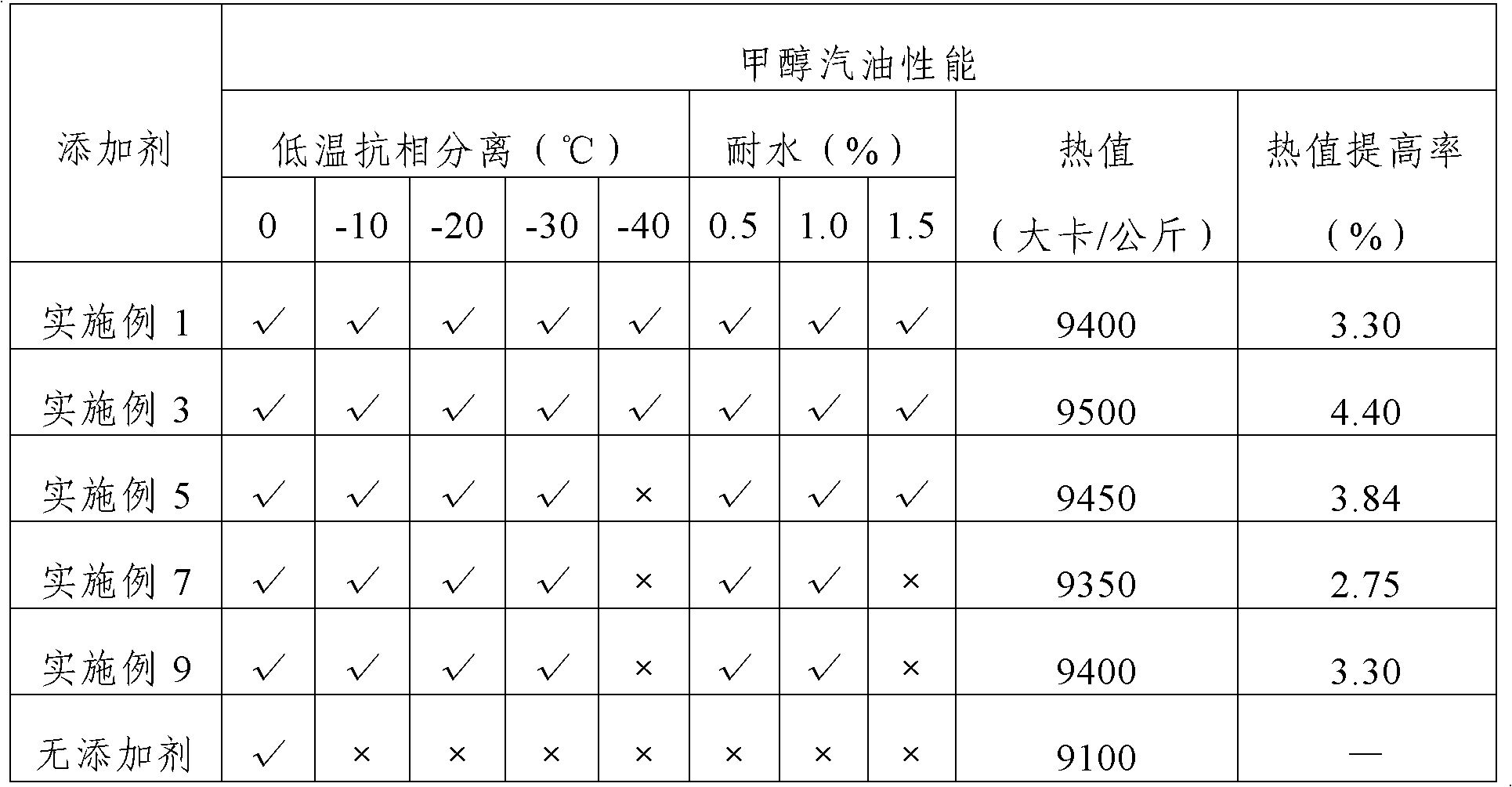

Examples

Embodiment 1

[0015] An additive for improving the anti-phase separation performance and calorific value of methanol gasoline, which is composed of the following raw materials in weight percent: fatty alcohol 35%, fatty ether 20%, fatty ester 30%, fatty acid 7%, fatty amine 5%, emulsifier OP 3 %; the fatty alcohol is isoamyl alcohol, the fatty ether is ethylene glycol propyl ether, the fatty ester is butyl acetate, the fatty acid is oleic acid, the fatty amine is dimethylamine, and the emulsifying Agent OP is emulsifier OP-15.

[0016] The preparation method of the additive in this example is as follows: mix the above-mentioned raw materials uniformly in proportion.

Embodiment 2

[0018] The additive of this embodiment is the same as that of Example 1, wherein the difference is that the fatty alcohol is isopropanol, n-propanol, n-pentanol or n-butanol, or is isopropanol, n-propanol, n-pentanol At least two of alcohol, isoamyl alcohol and n-butanol, the fatty ether is ethylene glycol ethyl ether or ethylene glycol butyl ether, or ethylene glycol propyl ether, ethylene glycol ethyl ether and ethylene glycol butyl ether At least two, the fatty ester is n-pentyl acetate or isoamyl acetate, or at least two of butyl acetate, n-pentyl acetate and isoamyl acetate, and the fatty acid is naphthenic acid, or is Oleic acid and naphthenic acid, the fatty amine is diethylamine, or dimethylamine and diethylamine, and the emulsifier OP is emulsifier OP-20, or emulsifier OP-15 and emulsifier OP- 20.

[0019] The preparation method of the additive in this embodiment is the same as that in Example 1.

Embodiment 3

[0021] An additive for improving the anti-phase separation performance and calorific value of methanol gasoline, which is composed of the following raw materials in weight percent: fatty alcohol 44%, fatty ether 15%, fatty ester 25%, fatty acid 10%, fatty amine 5%, emulsifier OP 1 %; the fatty alcohol is Virahol (14%) and n-amyl alcohol (30%), the fatty ether is ethylene glycol ether, the fatty ester is butyl acetate, and the fatty acid is oleic acid, the The fatty amine is dimethylamine, and the emulsifier OP is emulsifier OP-15.

[0022] The preparation method of the additive in this example is as follows: mix the above-mentioned raw materials uniformly in proportion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com