PC/ABS alloy possessing metal luster and its preparation method

A metal luster and alloy technology, which is applied in the field of PC/ABS alloy and its preparation, can solve the problems of potential safety hazards, explosions, and fires, and achieve the effects of not being prone to fires and explosions, reducing production costs, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

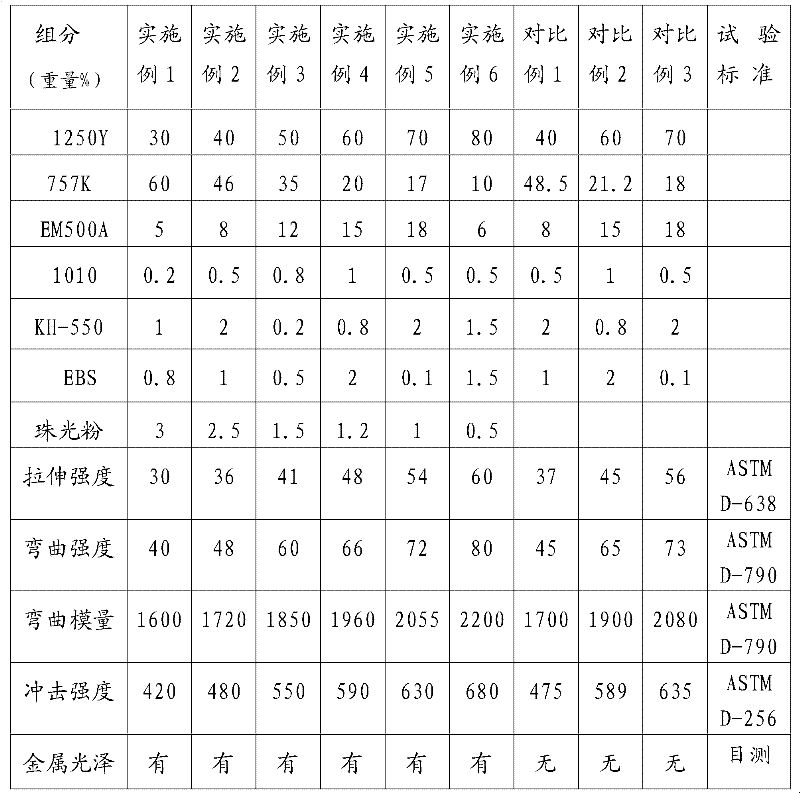

Embodiment 1

[0041] Polycarbonate (PC): 30% by weight percentage; ABS: 60%; Toughening agent: 5%; Antioxidant: 0.2%; Coupling agent: 1%; Processing aid: 0.8%; 3% is mixed in a high-speed mixer for 12 minutes, melted and extruded by a twin-screw extruder, and granulated. The temperature in the zone is 215°C, the temperature in the fifth zone is 235°C, the temperature in the sixth zone is 235°C, the temperature in the seventh zone is 235°C, and the temperature in the eighth zone is 240°C; the residence time in the barrel is 90S, and the melt pressure is 15MPa.

Embodiment 2

[0043] Polycarbonate (PC): 40% by weight percentage; ABS: 46%; Toughening agent: 8%; Antioxidant: 0.5%; Coupling agent: 2%; Processing aid: 1%; 2.5% is mixed in a high-speed mixer for 12 minutes, melted and extruded by a twin-screw extruder, and granulated. The temperature in the zone is 215°C, the temperature in the fifth zone is 235°C, the temperature in the sixth zone is 235°C, the temperature in the seventh zone is 235°C, and the temperature in the eighth zone is 240°C; the residence time in the barrel is 90S, and the melt pressure is 15MPa.

Embodiment 3

[0045] Polycarbonate (PC): 50% by weight percentage; ABS: 35%; Toughening agent: 12%; Antioxidant: 0.8%; Coupling agent: 0.2%; Processing aid: 0.5%; 1.5% is mixed in a high-speed mixer for 12 minutes, melted and extruded by a twin-screw extruder, and granulated. The temperature in the zone is 215°C, the temperature in the fifth zone is 235°C, the temperature in the sixth zone is 235°C, the temperature in the seventh zone is 235°C, and the temperature in the eighth zone is 240°C; the residence time in the barrel is 90S, and the melt pressure is 15MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com