Mechanical component mineral casting and mechanical component preparation method using the same

A technology of mechanical components and binders, applied in the field of mineral castings for mechanical parts, can solve problems such as inconsistent performance, affecting the application of resin mineral composite mechanical components, and low comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] sequence Granite particle size range (mm) % of total aggregate weight Remark 1 0.1-2 10 dry without impurities 2 2-4 10 dry without impurities 3 4-9 10 dry without impurities 4 9-14 16 dry without impurities 5 14-18 24 dry without impurities 6 18-20 30 dry without impurities

[0023] The binder is a mixture of epoxy resin, curing agent and diluent, wherein the epoxy resin is bisphenol A epoxy resin, accounting for 60% of the total weight, and the curing agent is an amine curing agent, accounting for 30% of the total weight, The diluent is propylene oxide allyl ether, accounting for 10% of the total weight; the filling material is ceramic powder, hollow glass microbeads or calcium carbonate powder with a particle size of less than 5 microns.

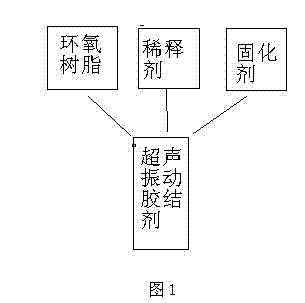

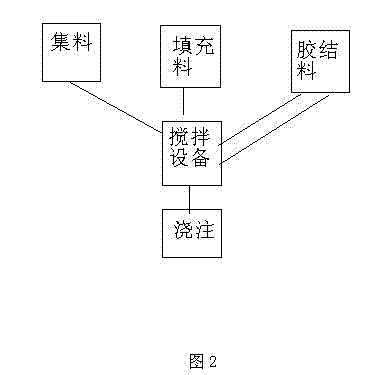

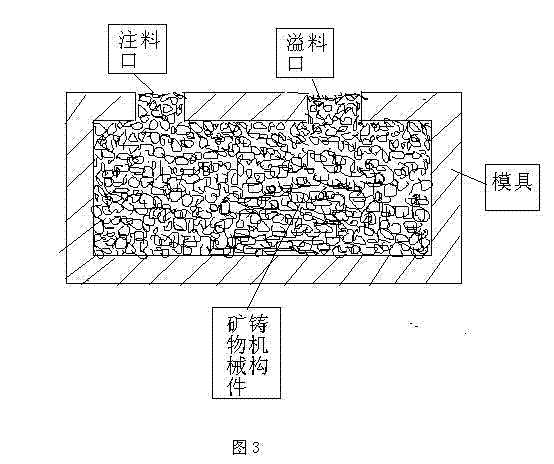

[0024] (2) Preparation of cementitious material: such as figure 1 As shown, the epoxy resin, the curing agent and the diluent...

Embodiment 2

[0030] sequence Granite particle size range (mm) % of total aggregate weight Remark 1 0.1-2 8 dry without impurities 2 2-4 9 dry without impurities 3 4-9 8 dry without impurities 4 9-14 10 dry without impurities 5 14-18 30 dry without impurities 6 18-20 35 dry without impurities

[0031] The binder is a mixture of epoxy resin, curing agent and diluent, wherein the epoxy resin is a bisphenol A epoxy resin, accounting for 75% of the total weight, and the curing agent is an amine curing agent, accounting for 20% of the total weight, The diluent is propylene oxide phenyl ether, accounting for 5% of the total weight; the filling material is a mixture of ceramic powder with a particle size of less than 5 microns, hollow glass microbeads and calcium carbonate powder in a mass ratio of 1:1:8.

[0032] According to the same method as steps (2)-(4) in Example 1, a sample block of 80*80*160mm was made, and the ...

Embodiment 3

[0034] sequence Granite particle size range (mm) % of total aggregate weight Remark 1 0.1-2 9 dry without impurities 2 2-4 9 dry without impurities 3 4-9 9 dry without impurities 4 9-14 18 dry without impurities 5 14-18 30 dry without impurities 6 18-20 25 dry without impurities

[0035] The binder is a mixture of epoxy resin, curing agent and diluent, wherein the epoxy resin is bisphenol A epoxy resin, accounting for 85% of the total weight, and the curing agent is an amine curing agent, accounting for 10% of the total weight, The diluent is a mixture of propylene oxide propylene ether and propylene oxide phenyl ether each accounting for 50% by mass, accounting for 5% of the total weight; the filler material is alumina powder with a particle size of 5 nanometers to 10 nanometers.

[0036]According to the same method as steps (2)-(4) in Example 1, a sample block of 80*80*160m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com