Apparatus for producing monofilaments or ribbons

A monofilament and strip technology, which is applied in the direction of artificial filament support, artificial filament physical therapy, winding strips, etc., can solve the problem of low-friction covering layer not being wear-resistant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

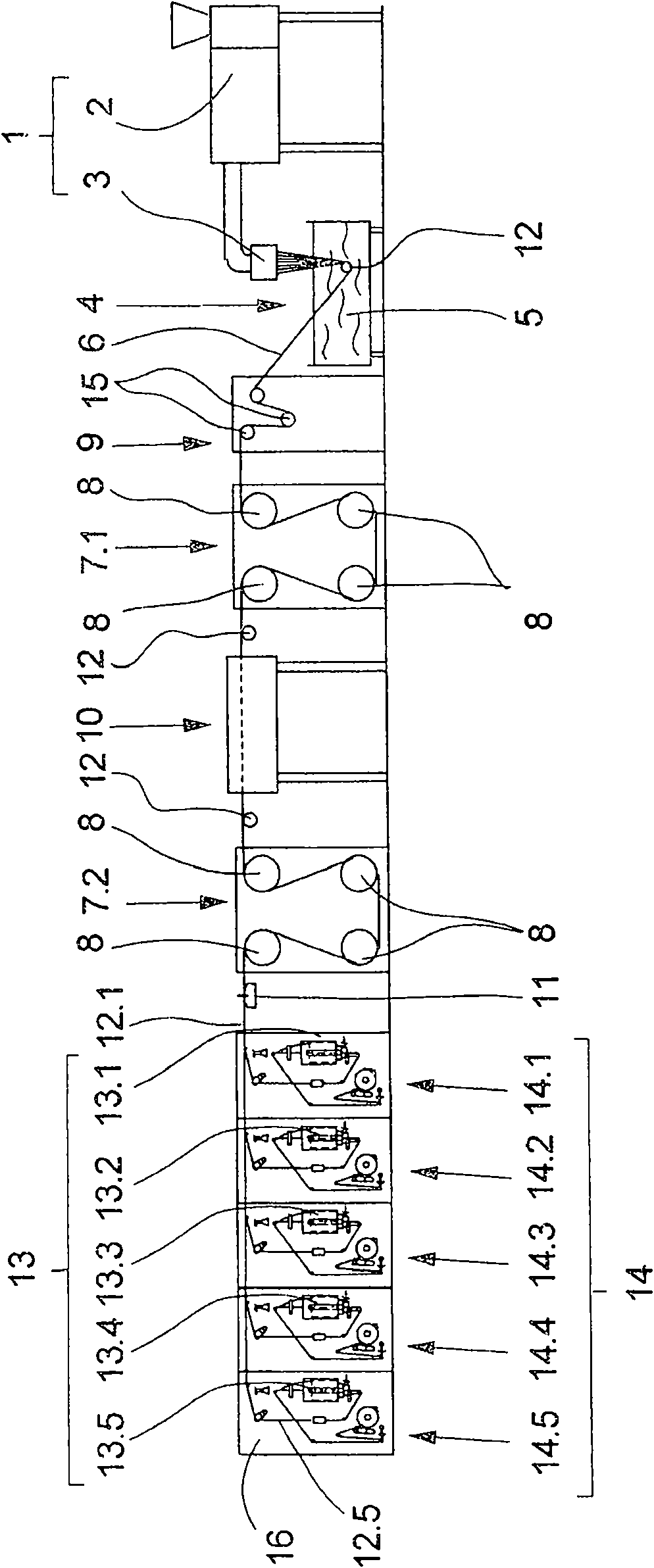

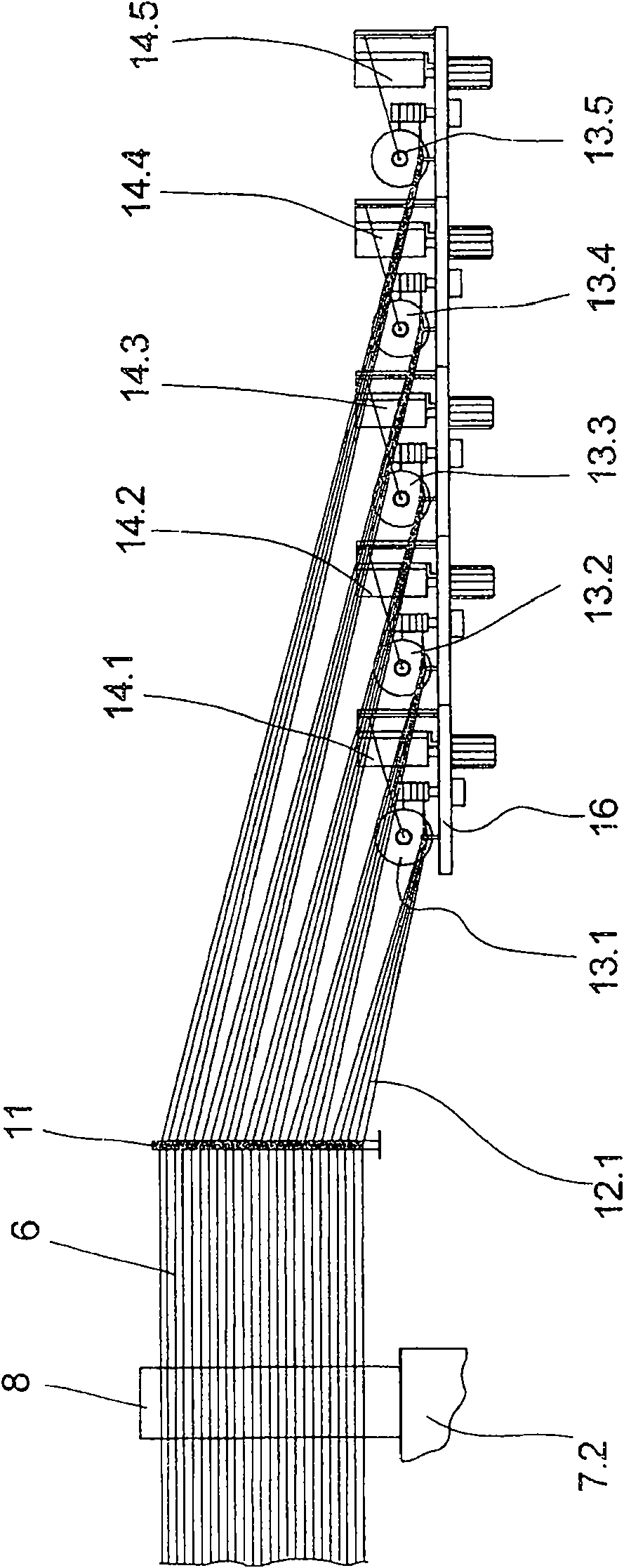

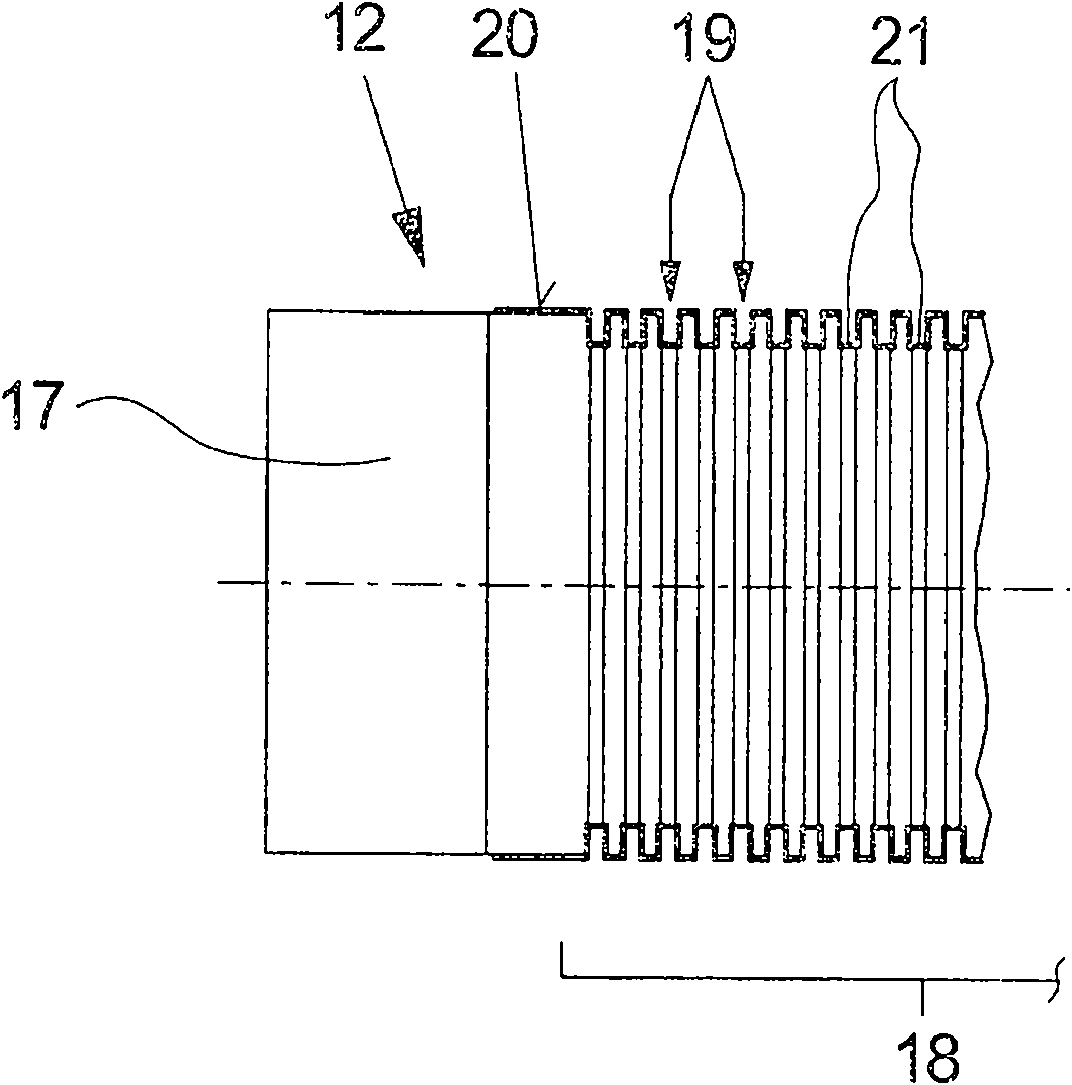

[0024] figure 1 and 2 An embodiment of the device according to the invention for producing monofilaments is shown schematically. figure 1 A general view of the embodiment is schematically shown in and, and figure 2 A partial view of the winding device and the winding device is schematically shown. The following description is directed to both figures, as long as no explicit reference is made to either of these figures.

[0025] figure 1 A general view of an embodiment of the device of the present invention is shown in . This embodiment has an extrusion device 1 for extruding thermoplastic material into a plurality of filaments. For this purpose, the extrusion device 1 has an extruder 2 and a spinneret 3 connected to the extruder 2 .

[0026] Downstream of the extruder, a plurality of processing units are provided for drawing the monofilaments or linking each of the plurality of monofilaments and winding them as a fiber bundle. In this exemplary embodiment, the first tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com