Single-sided circuit board made by arranging flat wires side by side and making method thereof

A flat wire and circuit board technology, which is applied in the directions of printed circuits connected with non-printed electrical components, printed circuit manufacturing, and assembling printed circuits with electrical components, can solve the problems of low efficiency, serious pollution, and high cost, and achieve elimination of Effects of chemical pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The details of one or more embodiments of the invention are set forth in the following description of the accompanying drawings and the detailed description. Other features, objects and advantages of the invention will be apparent from the description, drawings and claims.

[0049] Several specific embodiments of the method of manufacturing a single-sided circuit board by juxtaposing flat wires according to the present invention will be described in more detail below.

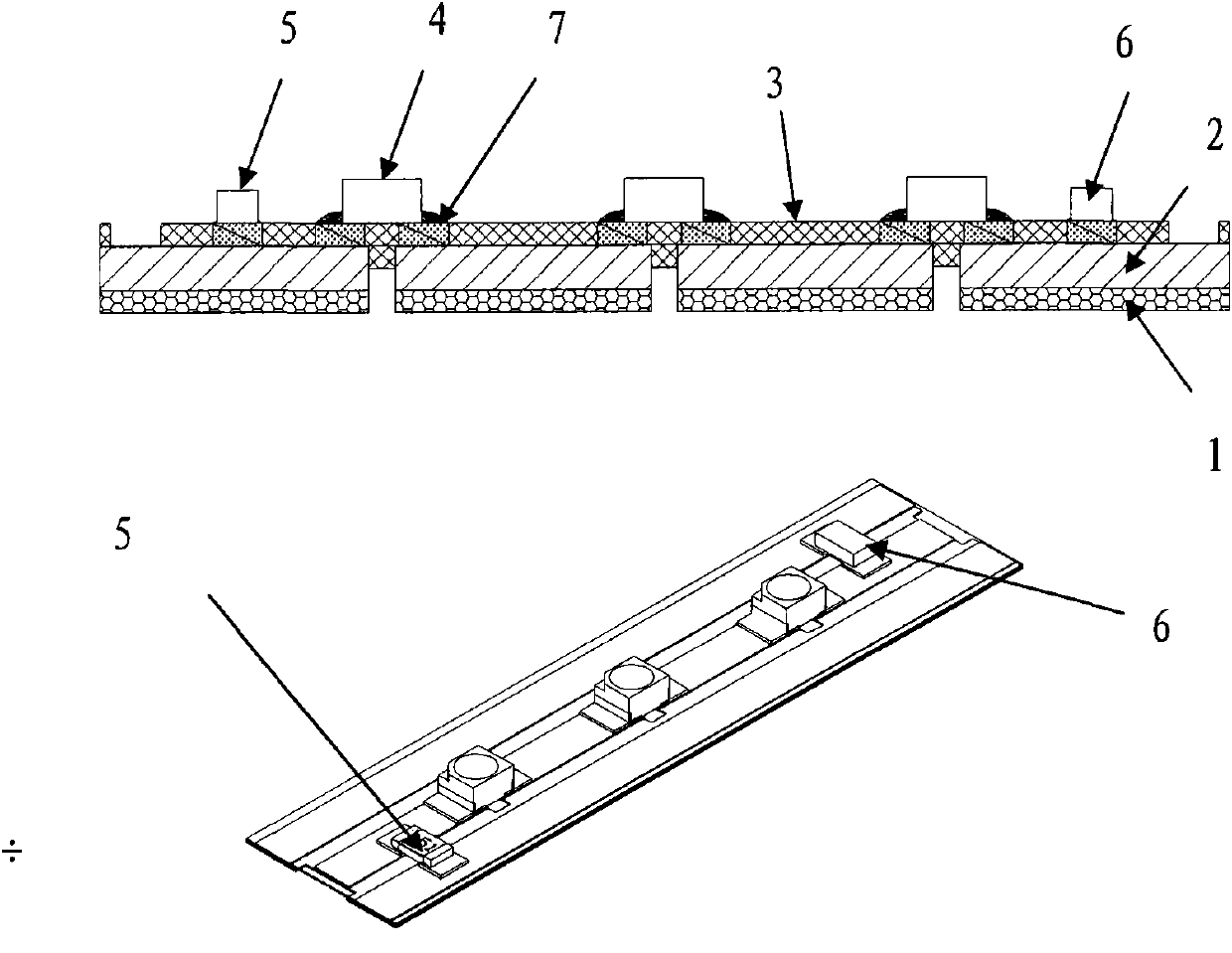

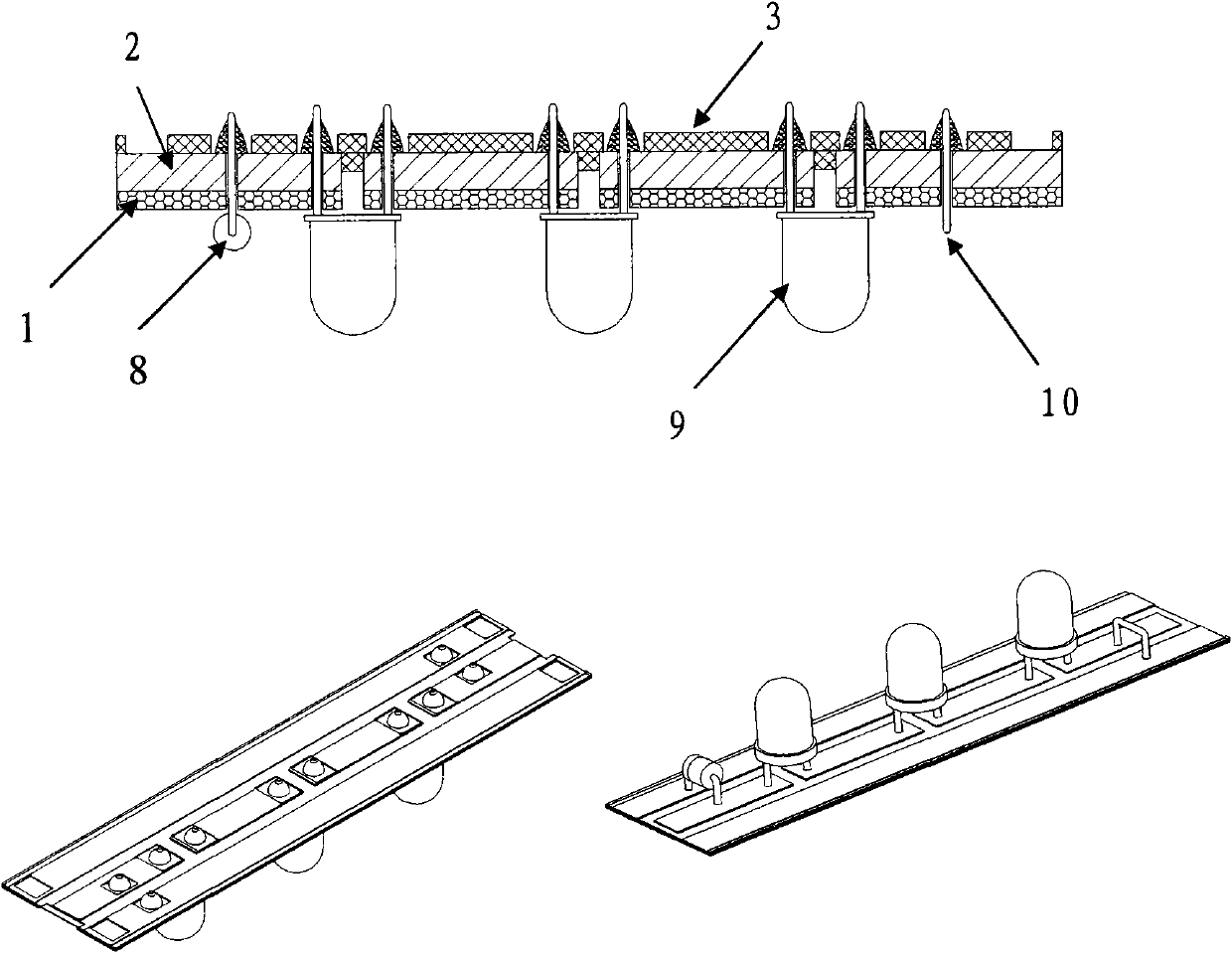

[0050] (1) Fabrication of rigid circuit board

[0051] 1. The production of the flat wire 2: the copper foil is cut into strips or the flat wire 2 is rolled with a flat wire calender or a flat wire 2 of a certain width and thickness (such as image 3 shown). This process is a traditional process and will not be described in detail here.

[0052] 2. Fabrication of juxtaposed groove molds: use mirror surface stainless steel plates such as etching or mechanical processing to process juxtaposed grooves 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com