Transition metal oxide/ graphene nanometer composite electrode material used for lithium battery and preparation method thereof

A transition metal, nanocomposite technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low lithium ion diffusion coefficient, unsatisfactory cycle performance, low electronic conductivity, etc., achieve excellent cycle performance, overcome transition metal The effect of oxide structure change and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

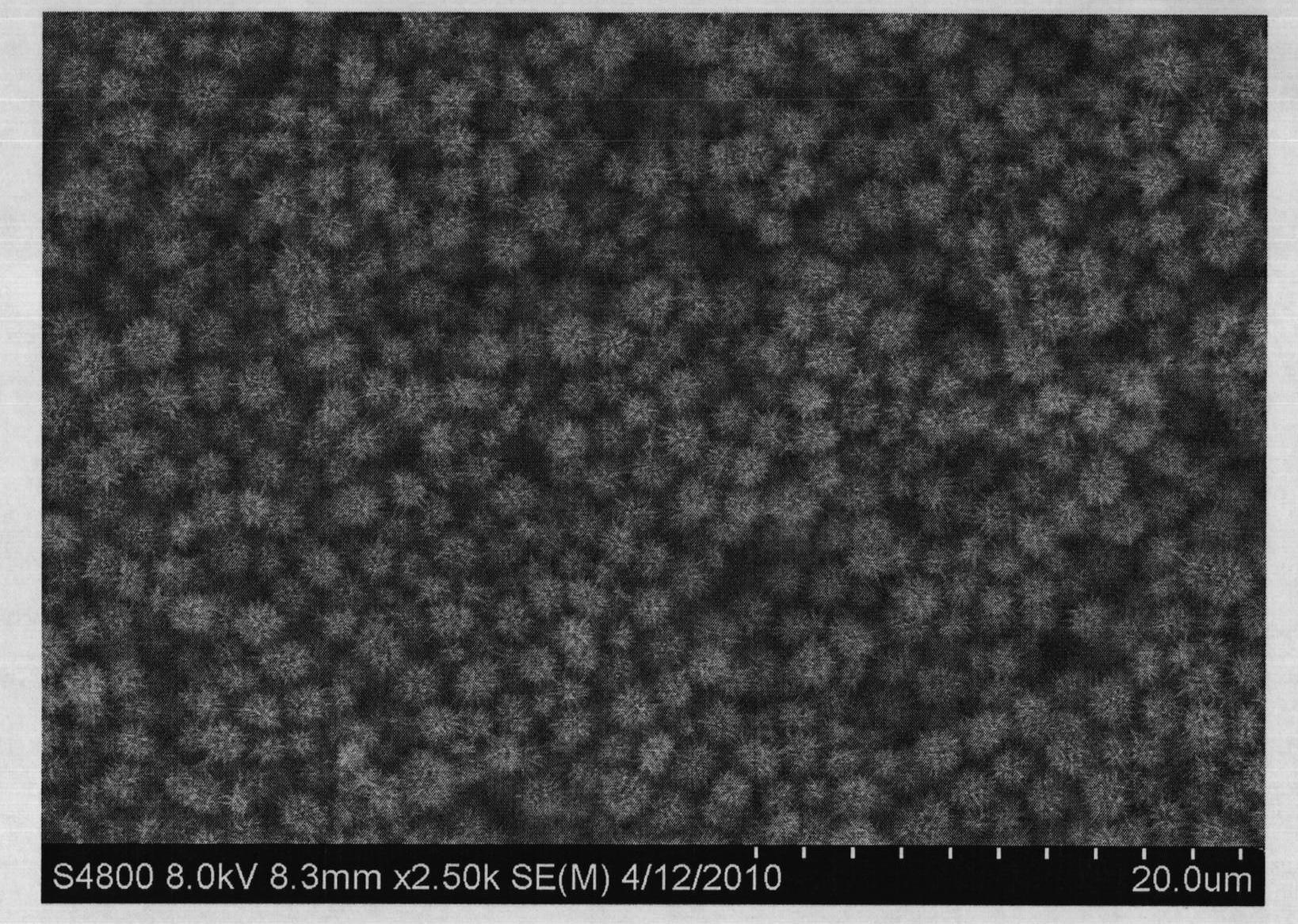

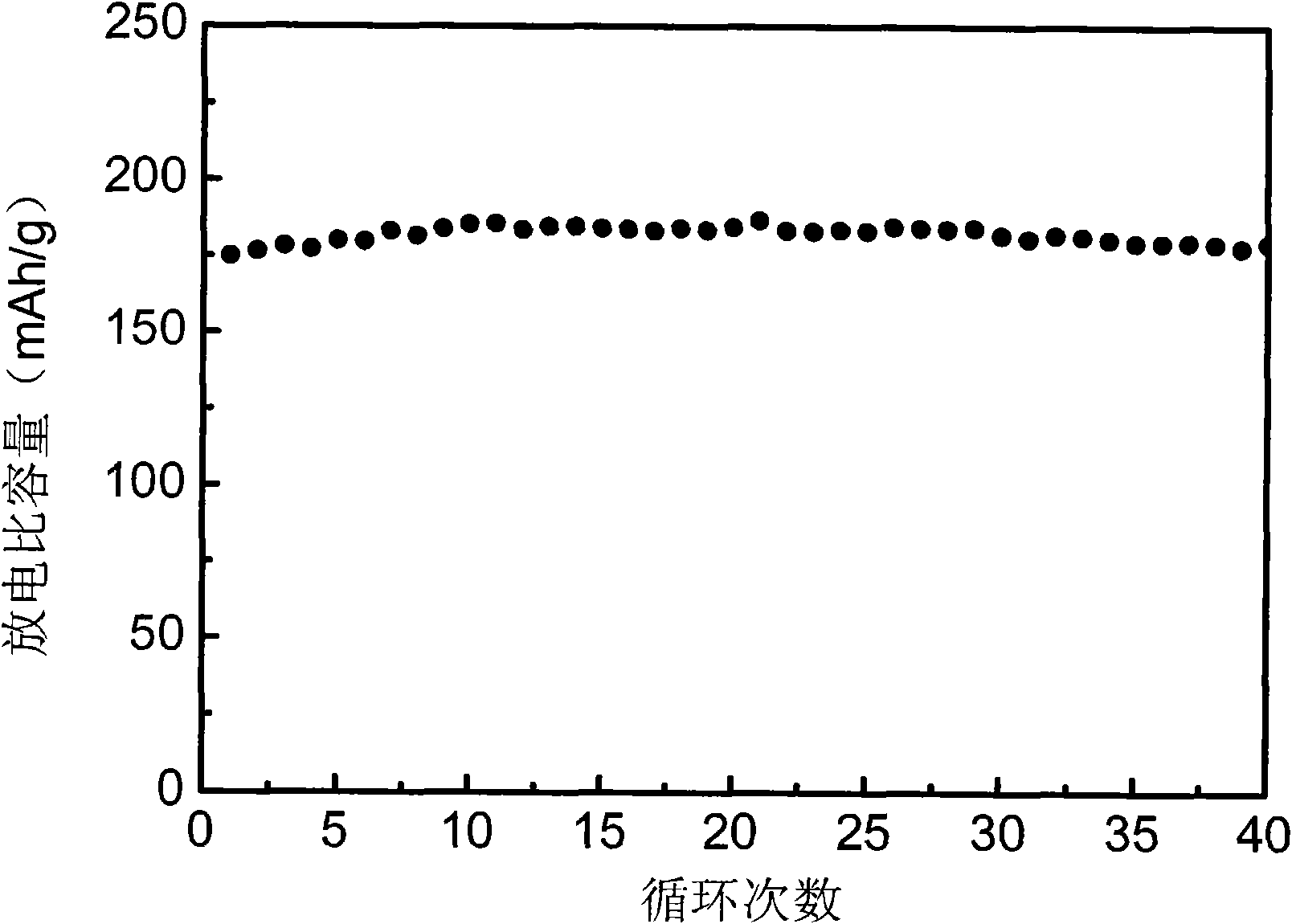

[0024] Preparation of manganese dioxide / graphene oxide nanocomposite electrode material: Manganese sulfate, ammonium persulfate and graphene oxide are used as raw materials, the molar ratio of manganese sulfate and ammonium persulfate is controlled to be 1:1, and graphene oxide is oxidized according to the theoretical product Add 10% of the manganese weight, mix uniformly in water for 1 hour, place in a high-pressure reactor at 90 degrees and react for 24 hours to obtain a manganese dioxide / graphene oxide nanocomposite electrode material for lithium batteries. figure 1 and 2 is the scanning electron microscope image of the composite electrode material.

[0025] The production of lithium secondary battery: the active material manganese dioxide / graphene oxide nanocomposite electrode material, the conductive agent Super P and the binder vinylidene fluoride are mixed uniformly in nitrogen methyl pyrrolidone according to the mass ratio of 85:10:5, and coated on an aluminum foil, a...

Embodiment 2

[0028] The preparation of the manganese dioxide / graphene oxide nanocomposite electrode material is the same as in Example 1, and this material is used as the electrode active material of the lithium battery to assemble a button battery. The production of the lithium secondary battery is basically the same as in Example 1, except that this material is used as the negative electrode active material, mixed evenly with the conductive agent Super P and the binder vinylidene fluoride nitrogen methyl pyrrolidone, and then coated on the copper foil Dry it at 80°C and use it as the negative electrode sheet of the battery. In the voltage range of 0.1V-2V, the constant current charge and discharge test shows that the reversible specific capacity of the battery is 1534mAh / g, and the capacity can be maintained above 950mAh / g after 50 cycles at 0.1C.

Embodiment 3

[0030] Manganese dioxide and graphene are fully mixed in an aqueous solution at a weight ratio of 90:10. The mixing method is mechanically stirred for 1 hour, then ultrasonicated for 30 minutes, spray-dried and granulated to obtain manganese dioxide / graphene nanoparticles for lithium batteries. Composite electrode material. Use this material as the electrode active material of the lithium battery, assemble the button battery, the making of the lithium secondary battery is the same as in Example 1, and in the voltage range of 1.5V-4.5V, the battery specific capacity is shown to be 180mAh through the constant current charging and discharging test / g, 100 cycles at 0.1C and attenuation of 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inverse specific capacity | aaaaa | aaaaa |

| Inverse specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com