High-reliability image sensor packaging structure without silicon through hole

An image sensor and packaging structure technology, applied in radiation control devices and other directions, can solve the problems of wafer-level image sensor packaging process difficulty, complex packaging structure, poor insulation in the hole, etc., to avoid poor reliability and process difficulty. The effect of reducing and simplifying the packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

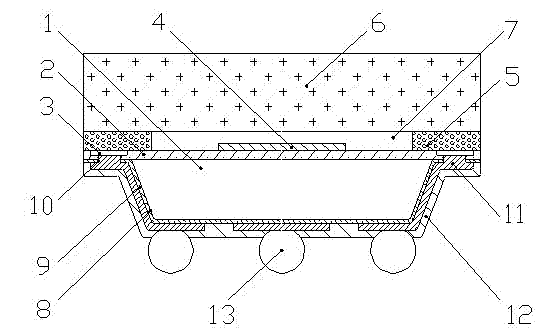

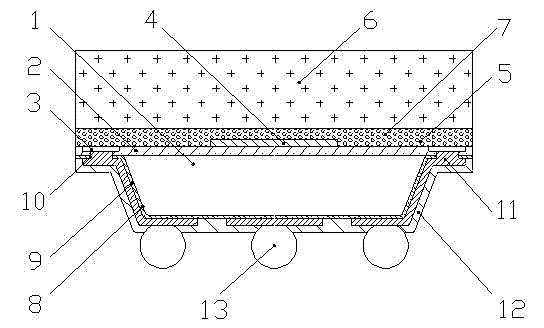

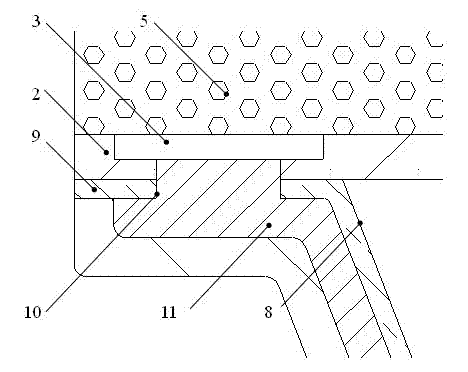

[0021] see figure 1 , figure 1 It is a cross-section schematic diagram of the packaging structure (with cavity type) of the high-reliability image sensor without through-silicon vias of the present invention. Depend on figure 1 It can be seen that the packaging structure of the high-reliability image sensor without TSVs in the present invention includes the chip body 1 provided with the passivation layer 2 inside the chip, the metal layer 3 inside the chip and the photosensitive area 4, the passivation layer inside the chip, the chip inside the chip Both the internal metal layer and the photosensitive area are structures of the image sensor chip itself, and do not belong to the packaging category involved in the patent of the present invention. An isolation layer 5 is provided on the upper surface of the chip body 1 , and the isolation layer 5 does not cover the photosensitive region 4 of the chip. A light-transmitting cover plate 6 is arranged on the isolation layer 5 . A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com