Plasma slab lens and near-field focusing method thereof

A technology of flat lens and plasma, which is applied in the direction of lens, optics, instruments, etc., can solve the problems that the center cannot be aligned with other structural centers at the same time, increase the cost of equipment, limit the application, etc., and achieve easy fabrication into lens arrays, easy Integrated, process-compatible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

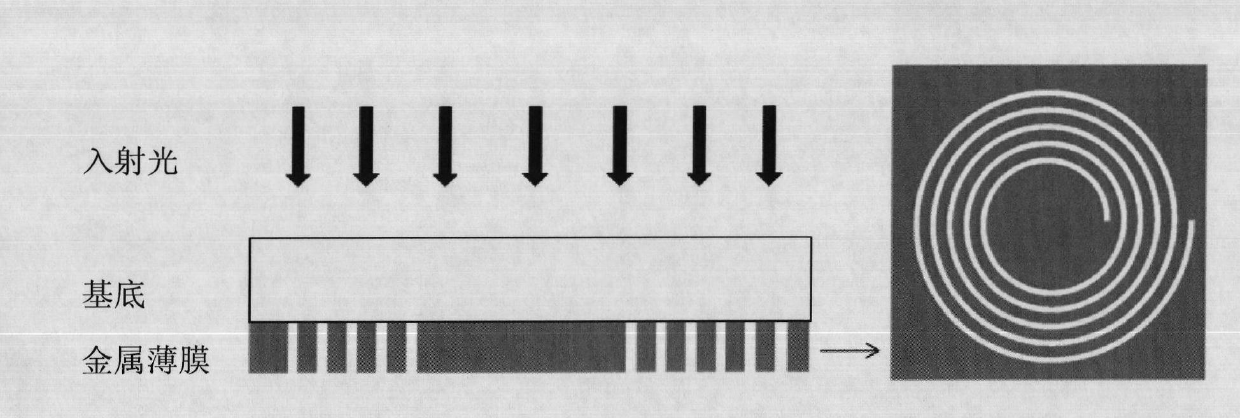

[0028] According to one embodiment of the present invention, a plasma slab lens is provided. Such as figure 1 As shown, the plasma flat lens includes a light-transmitting substrate (ie base) and a metal thin film fabricated on the substrate. A helical structure is processed on the metal film. figure 1 Among them, the left figure is the front view of the flat lens of this embodiment, and the right figure is the bottom view of the flat lens. The front view clearly shows the hierarchical structure of the flat lens of this embodiment, and shows the incident direction of light, and the bottom view clearly shows the helical structure on the metal film.

[0029] In this embodiment, it is required that the material of the substrate must have good light transmittance, and must also be a stable and reliable material capable of withstanding a certain laser powe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Seam width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com