Horn sounding tester of steering wheel

A steering wheel and testing machine technology, applied in the mechanical field, can solve the problems of unsatisfactory cooling effect, untestable samples, slow mechanical system, etc., to achieve the effect of easy movement, light structure and stable running performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described now in conjunction with accompanying drawing.

[0035] one,

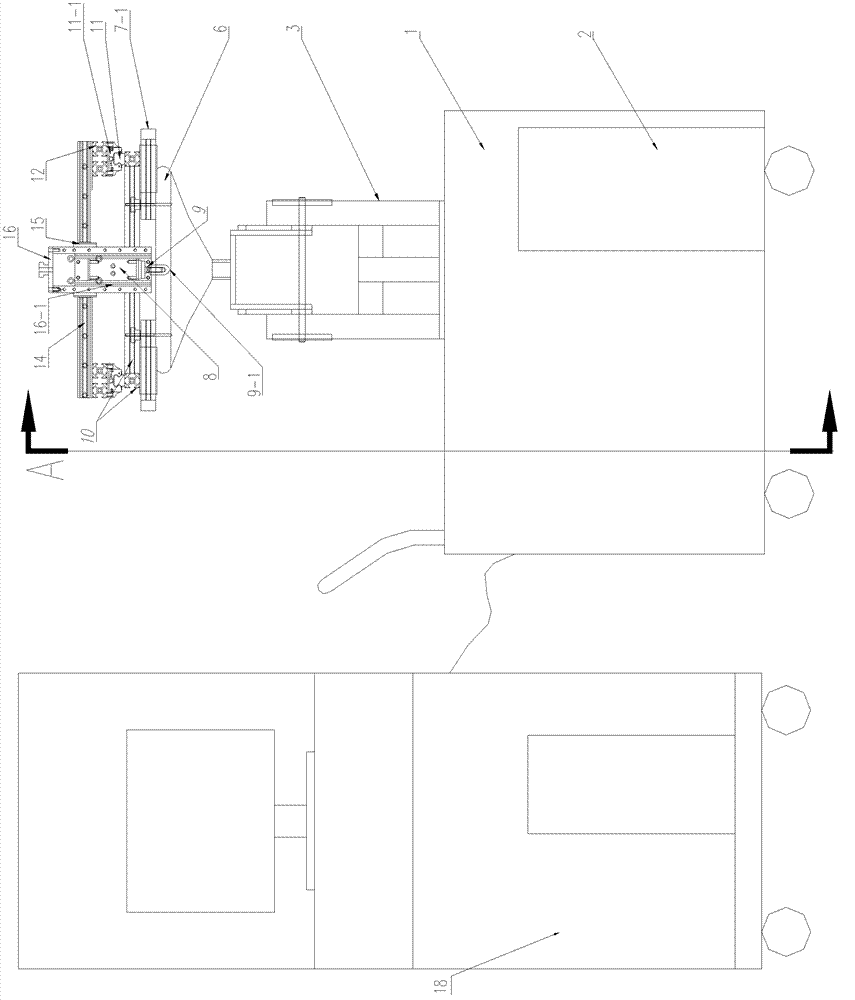

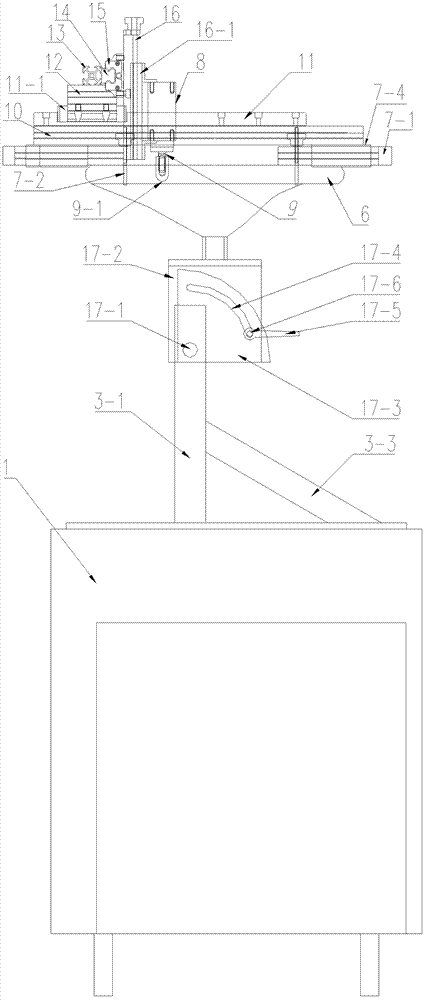

[0036] see Figure 1 to Figure 6 , The present invention includes a mobile control display cabinet, a microcomputer embedded with LabVIEW processing software, a trolley, a pneumatic control box, a pneumatic integrated module, an air source treatment and conditioning device, and an adjustable sample clamping device.

[0037] Establish a mobile control display cabinet 18 and a cart 1, place the steering wheel clamping device on the cart 1; place the pneumatic control box 2 in the box of the cart 1, and the pneumatic control box 2 is controlled by the embedded in the mobile control display cabinet 18. Microcomputer control with LabVIEW software, among them,

[0038] Steering wheel clamping device, the bottom of which is an adjustable angle base, the adjustable angle base is provided with two left and right struts 3-1, the inner side walls of the left and right t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com