Rotary type compressor and gas-liquid separator thereof

A technology of rotary compressor and gas-liquid separator, applied in the direction of rotary piston/swing piston pump components, machine/engine, pump combination for elastic fluid rotary piston/swing piston type, etc., can solve Poor inter-cooling effect of single-unit two-stage compressor, large double-unit two-stage compression system cannot apply small-displacement air conditioners, low energy efficiency level, etc., to achieve the effect of improving energy efficiency level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0020] The first embodiment of the gas-liquid separator according to the present invention will be described in detail below with reference to the accompanying drawings.

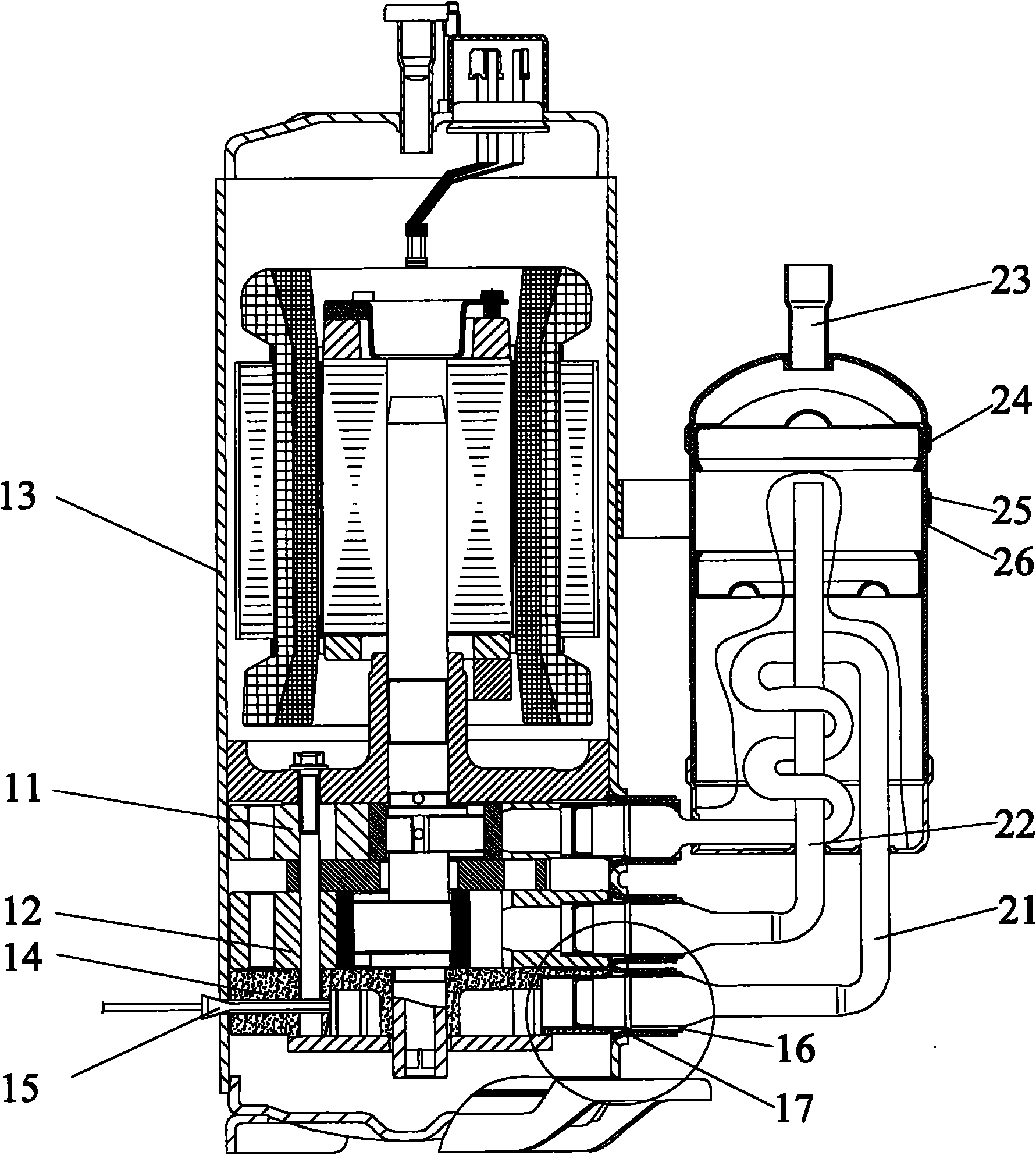

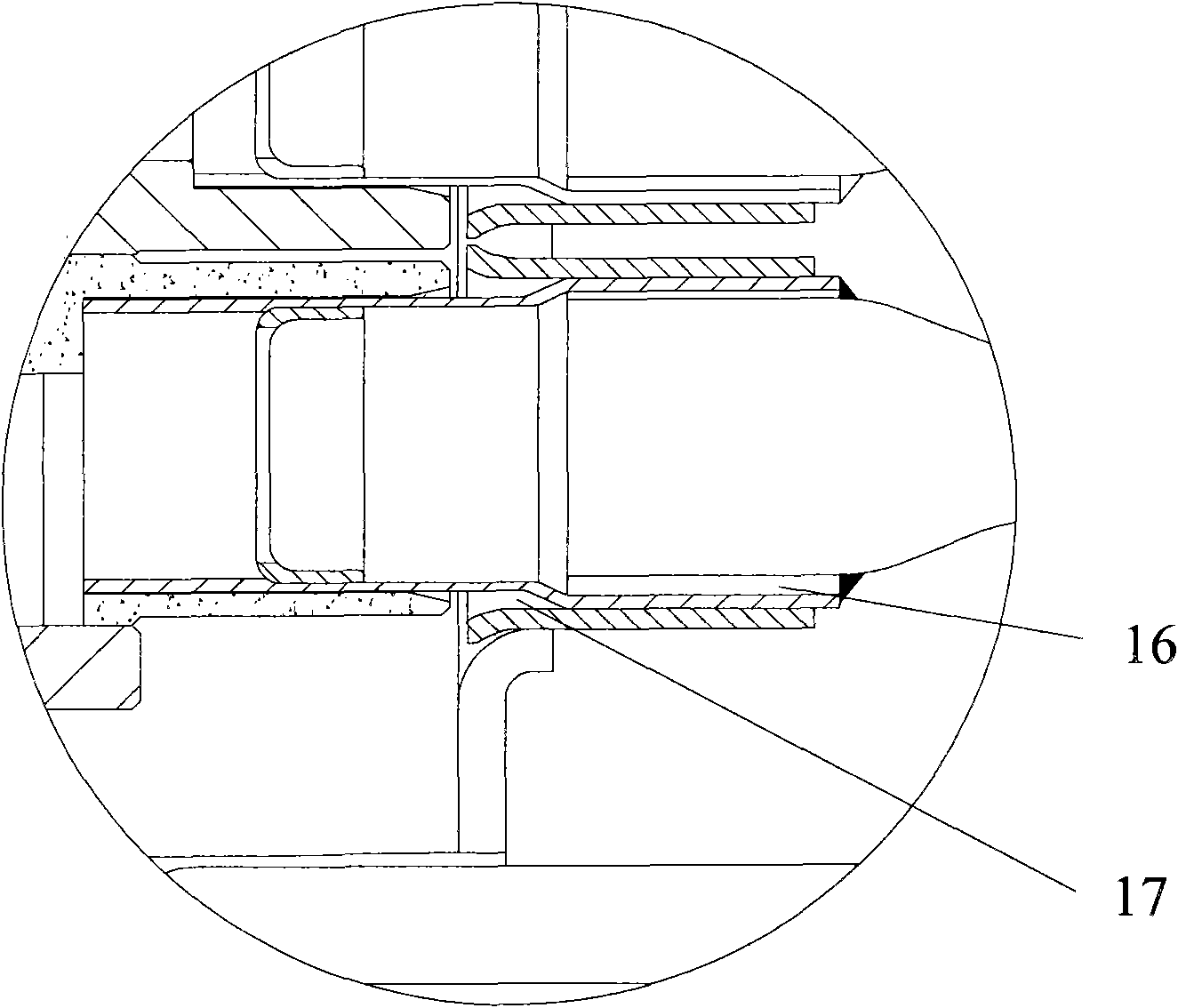

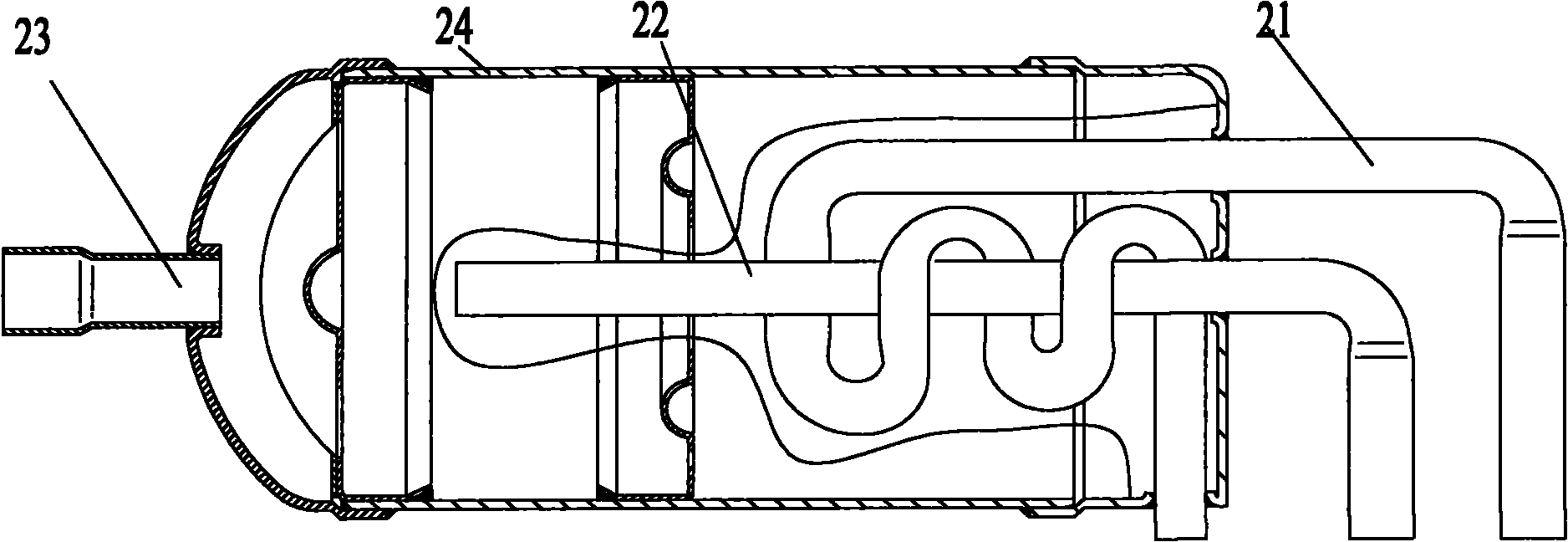

[0021] Such as figure 1 , image 3 and Figure 4 As shown, the gas-liquid separator includes: a liquid separator cylinder 24, a suction pipe 23, an exhaust pipe 22 and a connecting pipe 21 fixedly connected to the liquid separator cylinder 24 respectively, and the first end of the connecting pipe 21 is connected to the rotating The cavity of the lower flange 14 connected to the discharge side of the low-pressure compression structure 12 of the type compressor communicates with and penetrates into the liquid distributor cylinder 24, and its second end passes through the liquid distributor cylinder 24 and It communicates with the suction cavity of the high-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com