Gas-water separation, water discharging and slag discharge integrated device for drill hole in gas extraction crossheading drill site

A technology of gas drainage and gas-water separator, which is applied in the direction of gas discharge, safety devices, separation methods, etc. It can solve the problems of inconvenient use on site, affecting the effect of drainage, and small water release, and achieves convenient maintenance and on-site use , good water discharge effect and increased water release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

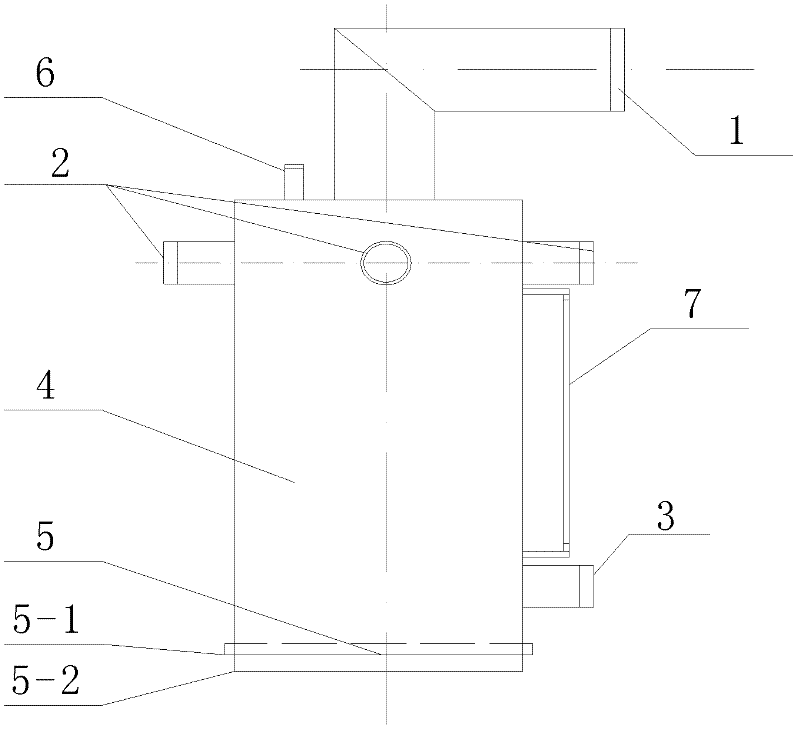

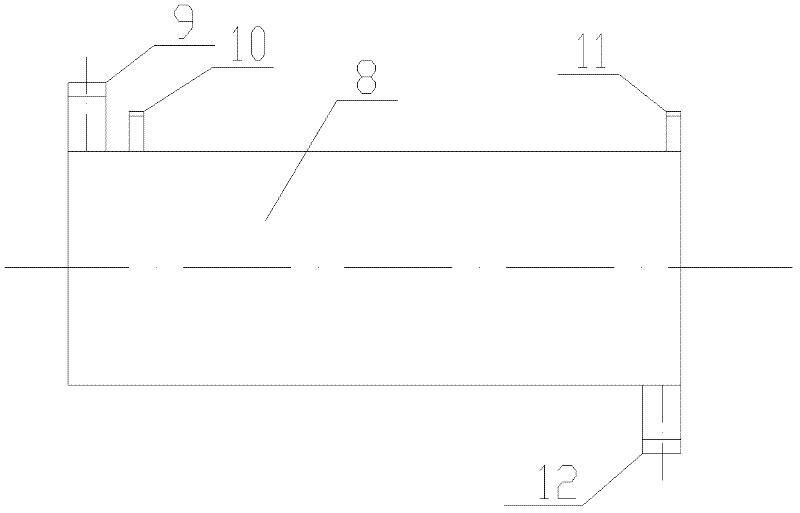

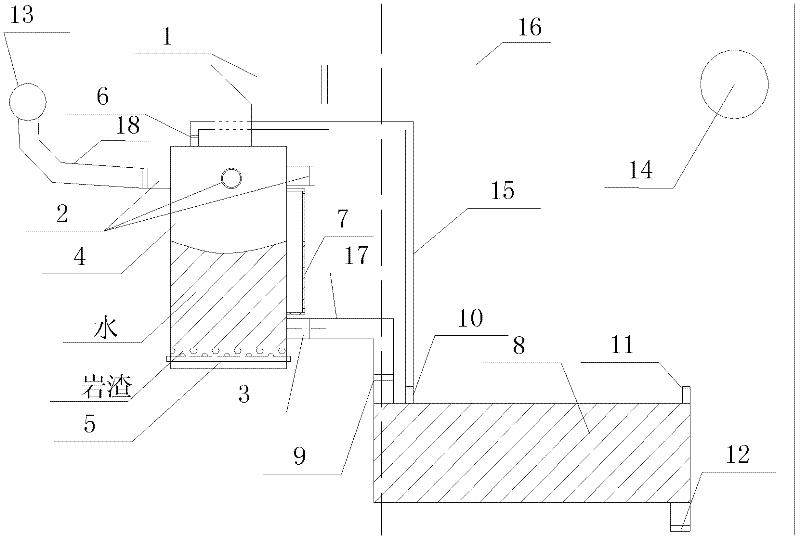

[0028] An integrated gas-water separator, water discharge and slag discharge integrated device for gas drainage drilling site, including gas-water separator and water discharge device, the structure is as follows Figure 1-4 shown.

[0029] The tank body 4 of the gas-water separator is a Φ273mm steel cylindrical container with a height of 0.6m. On the wall of the container, there are 4 drill holes connected to the nozzles 2 in a circular, symmetrical and equidistant manner. The 4 drilled holes connected to the nozzles 2 are all For the Φ50mm nozzle with valve, the 4 drill holes connect the nozzle 2 with the drill hole 13 in the drill field along the groove through the rubber hose 18 with a steel wire skeleton in the pipe wall, and the 4 drill holes can be Simultaneously communicate with respectively 4 boreholes in the drill field along the groove, also can only connect the borehole 13 in the drill field along the groove as required (such as image 3 shown), or connect 3 boreho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com