Blade swirl-type dilution mixer for gas drainage

A blade swirl and gas extraction technology, which is applied in the field of ultra-low concentration methane thermal countercurrent oxidation and low-density energy recovery, can solve the problems of large flow resistance, increased energy consumption of transport gas, complex structure, etc., and avoid friction explosion. , The effect of reducing transmission power consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

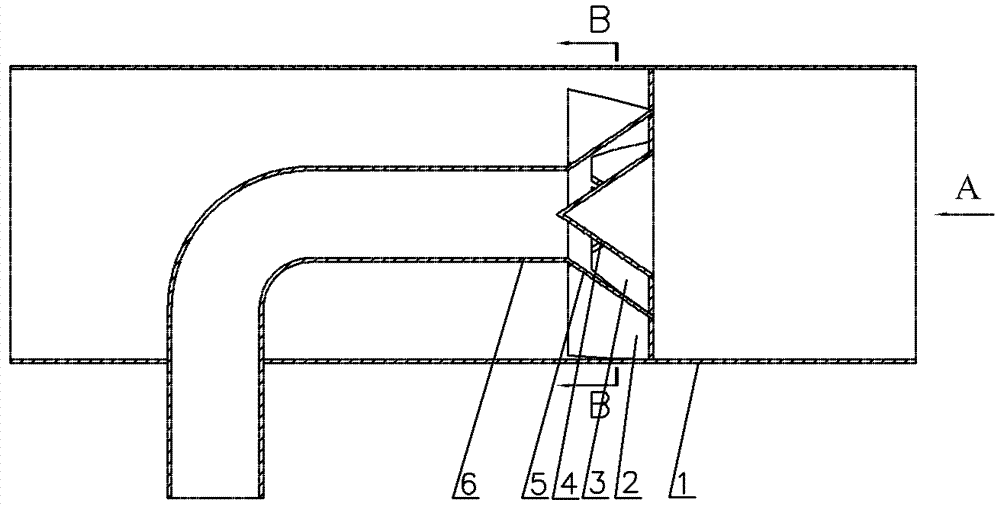

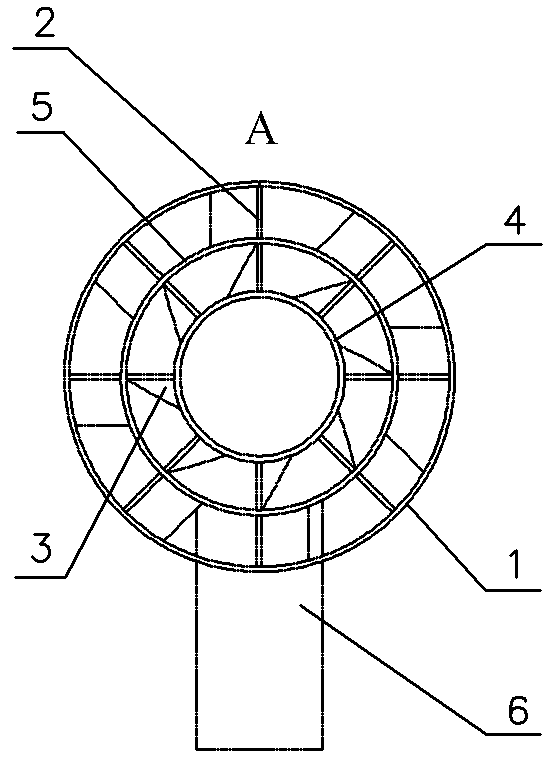

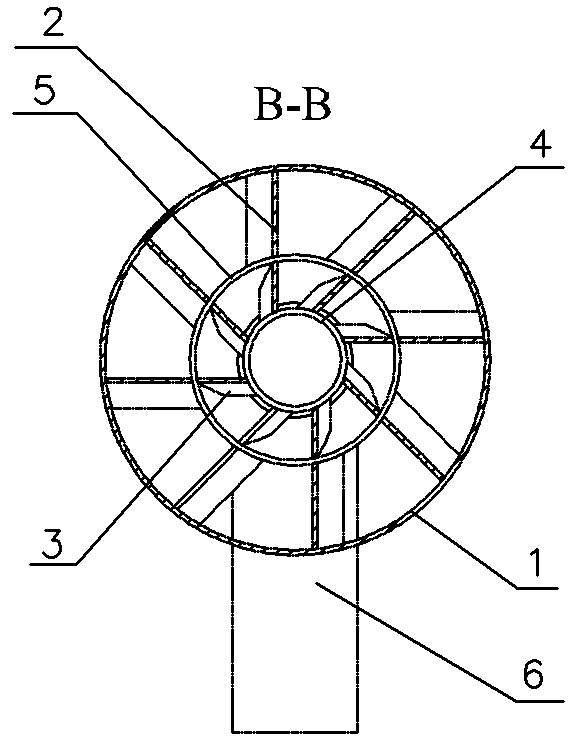

[0020] exist Figure 1-3 In the shown embodiment: it includes a tubular casing 1, a gas injection pipe, an inner deflection vane 3, an outer deflection vane 2, and a guide cone 4, and the gas injection pipe includes an inlet pipe 6 and a gas outlet installed at the outlet end of the inlet pipe 6. Expansion tube 5, wherein the pipe diameters of housing 1 and inlet pipe 6 are constant, expansion tube 5 adopts a variable diameter tube with gradually larger inner diameter, and the expansion angle is 60°, and the cross-sectional area of the outlet end of expansion tube 5 is the cross-sectional area of housing 1 65%, the axial distance between the outlet end and the outlet end of the housing 1 is three times the diameter of the housing 1, the inlet pipe 6 is a 90° elbow, and the axial distance between the elbow and the outlet end of the expansion tube 5 The distance is 8 times the diameter of the inlet pipe 6, the inlet end of the inlet pipe 6 is set outside the housing 1, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com