Novel composite maintaining method of hinged joint of bridge

A new method, a compound method technology, applied in bridges, bridge maintenance, bridge reinforcement, etc., can solve problems such as plate girder fracture, plate girder hinge joints are easily damaged, and damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

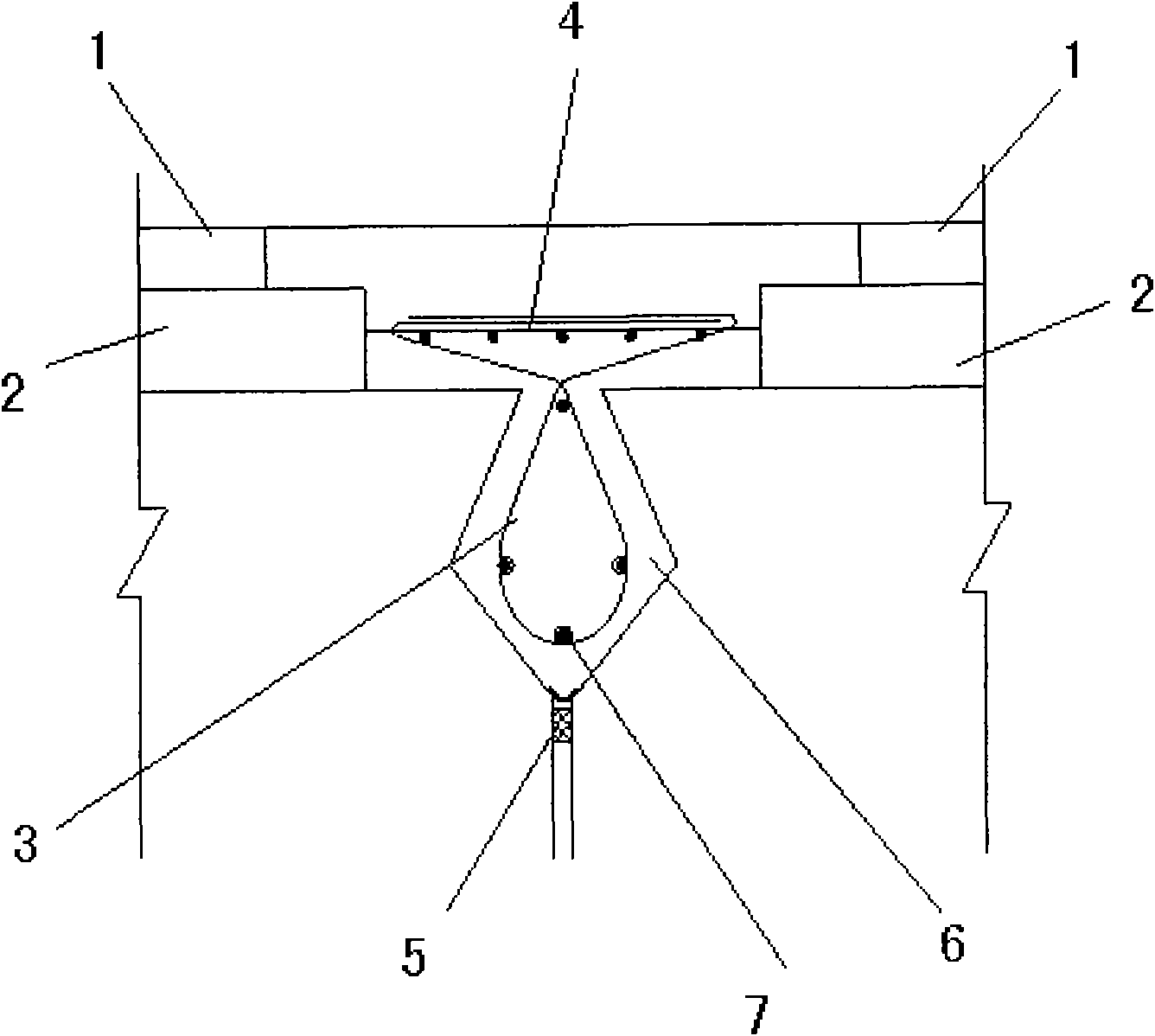

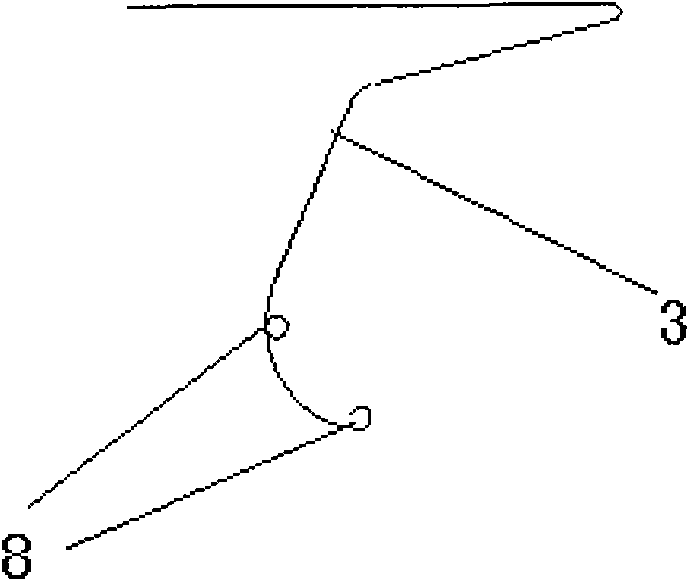

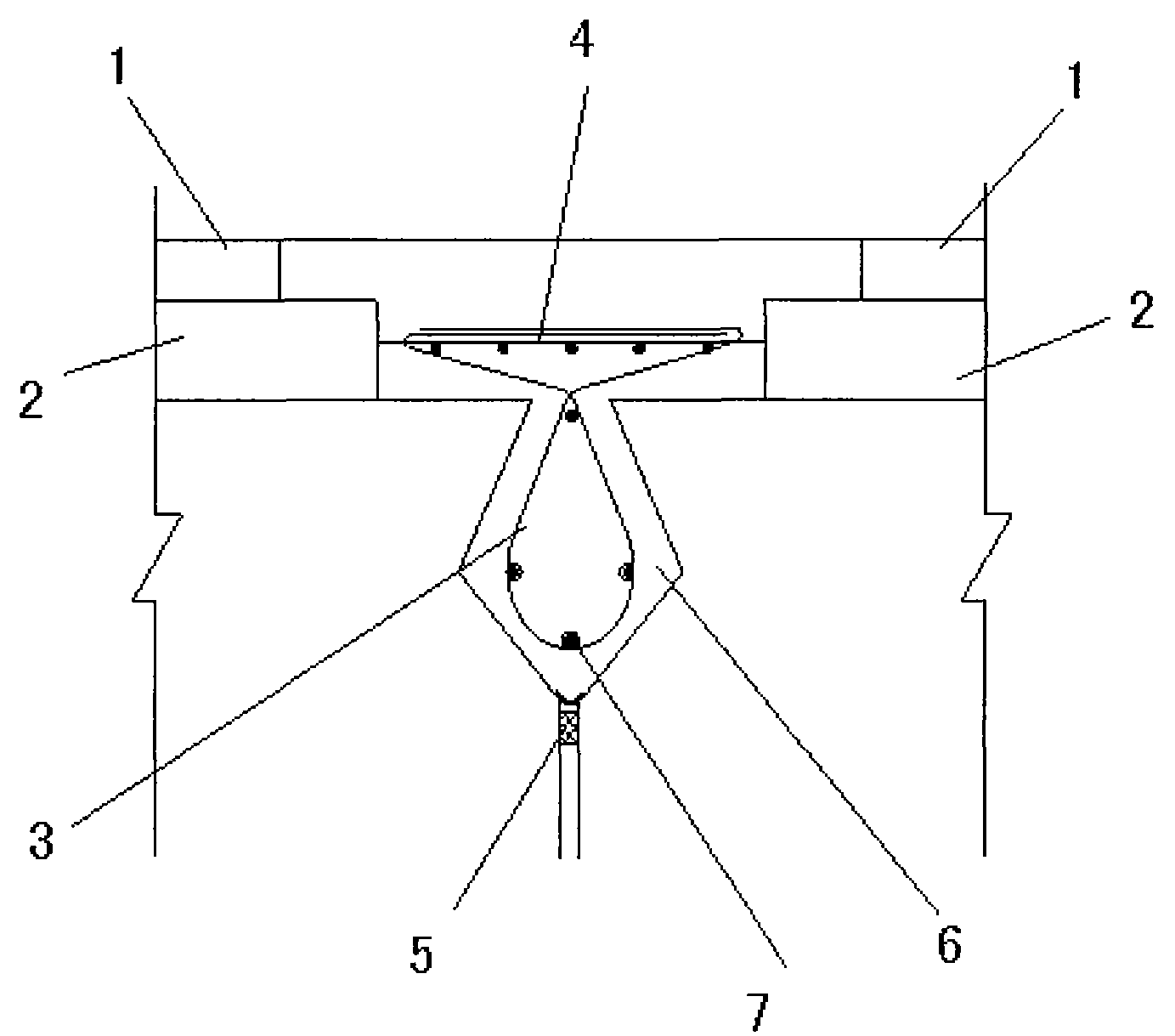

[0007] Remove the damaged asphalt layer and cement paving layer on both sides of the bridge hinges that need repair, remove the damaged concrete in the slab beam chamfer, and use plastic foam and tape in the gap at the bottom of the slab beam chamfer Closed, install the folding steel cage in the chamfer at the hinge joint of the slab beam, the folded steel cage that will be divided into two halves is put into the slab beam chamfer one by one along the slab beam chamfer, and the multiple is divided into two halves The folded steel cage is connected by straight steel bars penetrating into the circle on the folding steel cage, and then the steel bars on the upper part of the folding steel cage are connected with the steel bars on the original bridge deck and the additional steel mesh. The chamfer at the joints and the pavement layer of the bridge deck are cast with fast concrete to maintain the fast concrete. After the fast concrete reaches the specified strength, pave the elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com