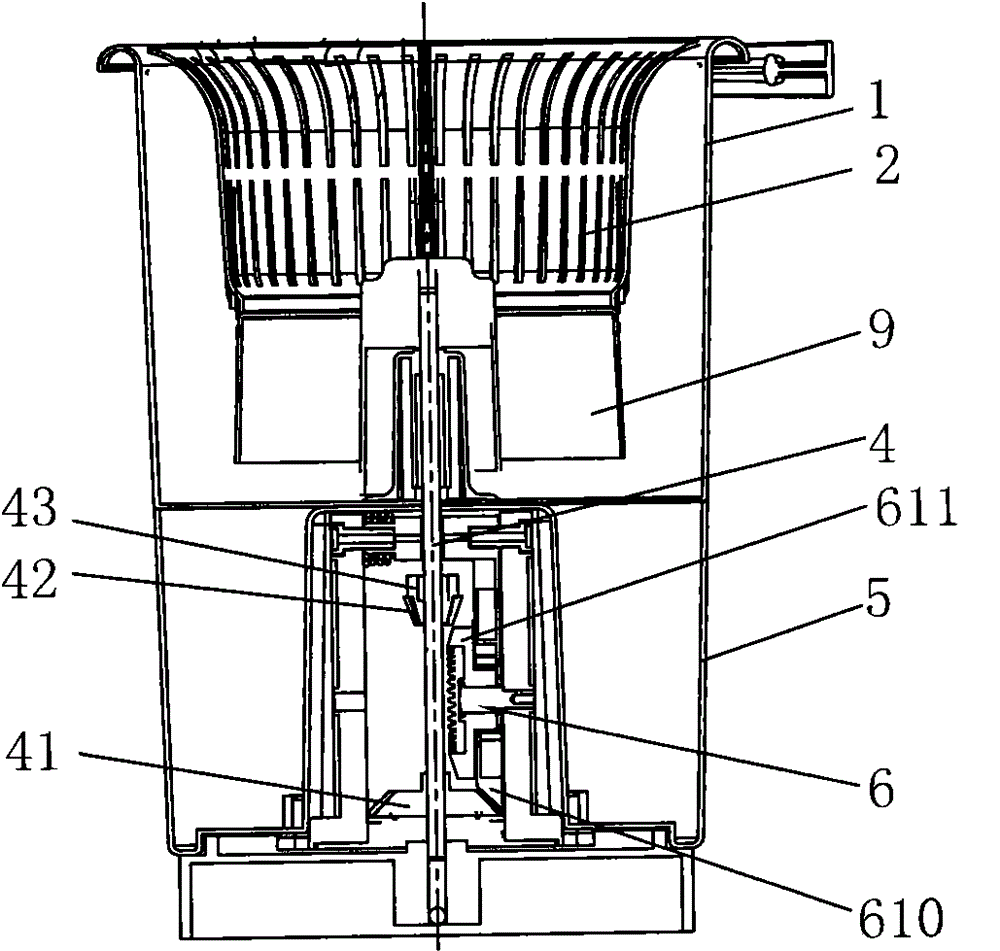

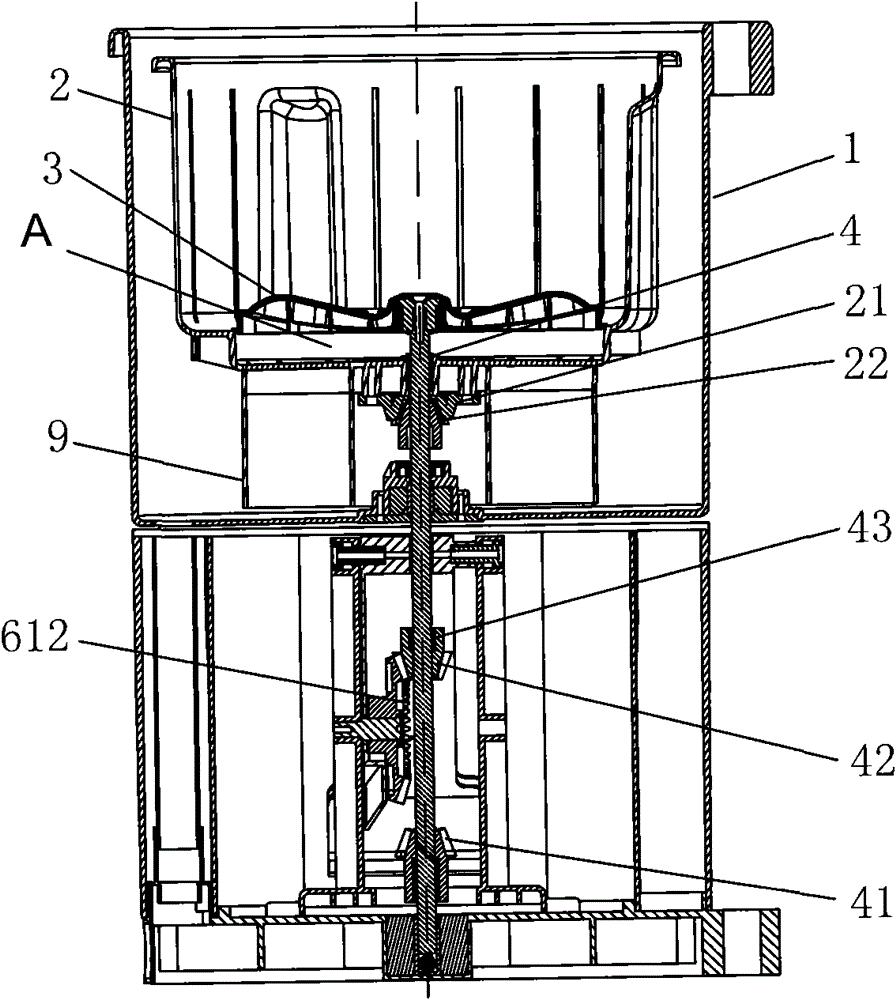

A sports washing machine with shock absorbing function

A washing machine and sports technology, applied in the field of washing machines, can solve the problems of easy damage, high maintenance rate, loud noise, etc., and achieve the effect of facilitating maintenance, improving performance, and reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Such as Image 6 As shown, the shock absorbing device described in this embodiment includes a plurality of sets of upper and lower positioning columns 10, 11 respectively arranged at the bottom of the barrel body 1 and the upper part of the base 5, and the upper and lower positioning columns 10, 11 correspond to each other as follows: One group, each set of upper and lower positioning columns 10, 11 is covered with an elastic shock absorbing ring 12, and the height of the elastic shock absorbing ring 12 is greater than the sum of the heights of the upper and lower positioning columns 10, 11.

Embodiment 2

[0044] Such as Figure 7 As shown, the damping device described in this embodiment includes multiple sets of upper positioning columns 13 and lower positioning holes 14 respectively located at the bottom of the barrel body 1 and the upper part of the base 5. The upper positioning columns 13 and the lower positioning holes 14 are arranged one by one. Correspondingly be one group, the outside of upper positioning post 13 is all covered with elastic shock absorbing ring 12, the height of this elastic shock absorbing ring 12 is greater than the depth of upper positioning post 13 height and lower positioning hole 14, elastic shock absorbing ring 12 and upper positioning post 13 are inserted in the lower positioning hole 14 together.

Embodiment 3

[0046] The difference between this embodiment and the above-mentioned embodiments is that an upper positioning hole is provided at the bottom of the bucket body, and a lower positioning column is provided at the upper part of the base. The shock absorbing device also includes a plurality of sets of upper positioning holes and lower positioning posts respectively arranged at the connection between the bottom of the bucket body and the upper part of the base. There is an elastic shock absorbing ring, the height of which is greater than the height of the lower positioning post and the depth of the upper positioning hole, and the elastic shock absorbing ring is inserted in the upper positioning hole together with the lower positioning post.

[0047] The elastic damping ring in the above three embodiments is a rubber ring or an O-ring, and the height of the elastic damping ring is such that the upper and lower positioning posts or the upper positioning post and the lower positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com