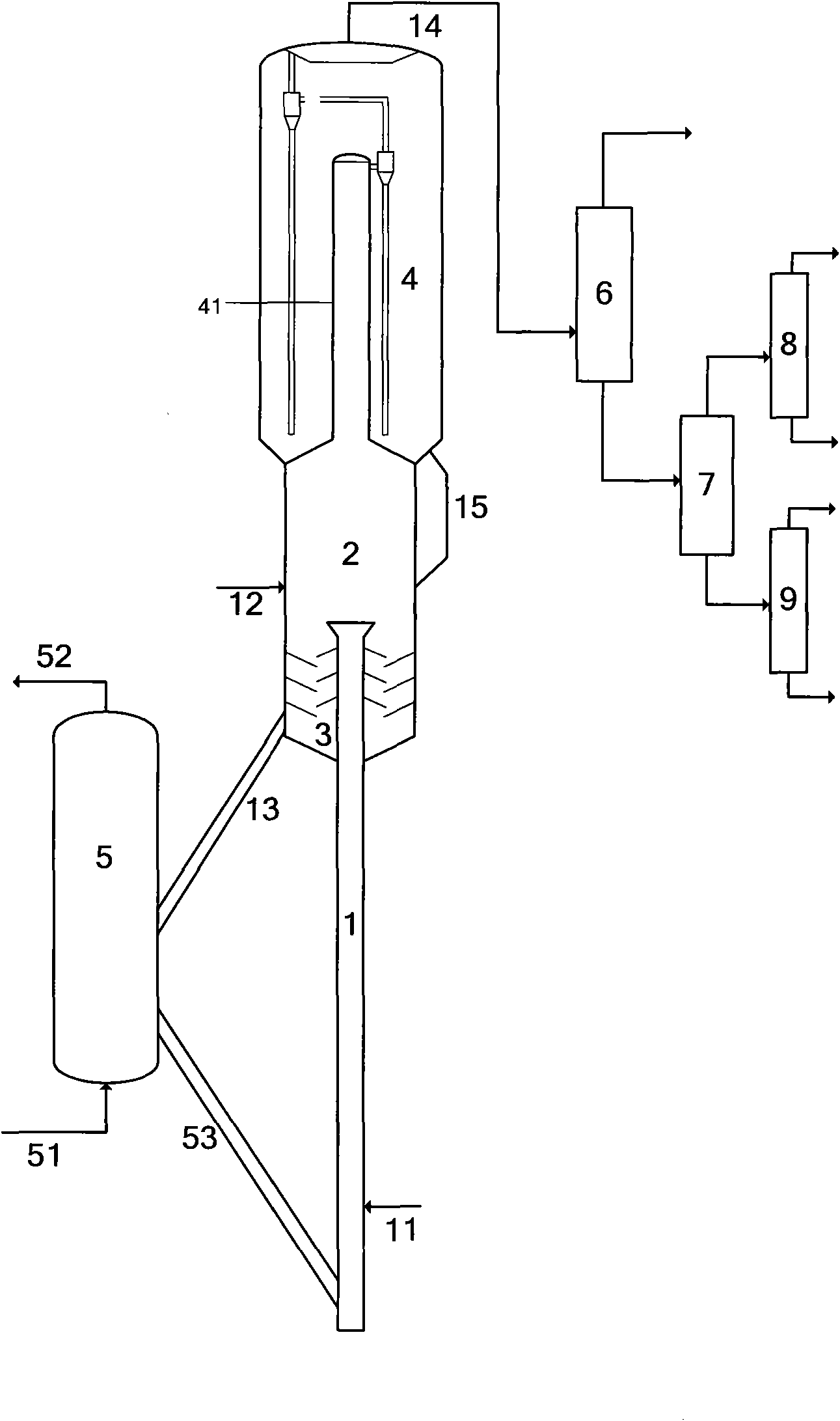

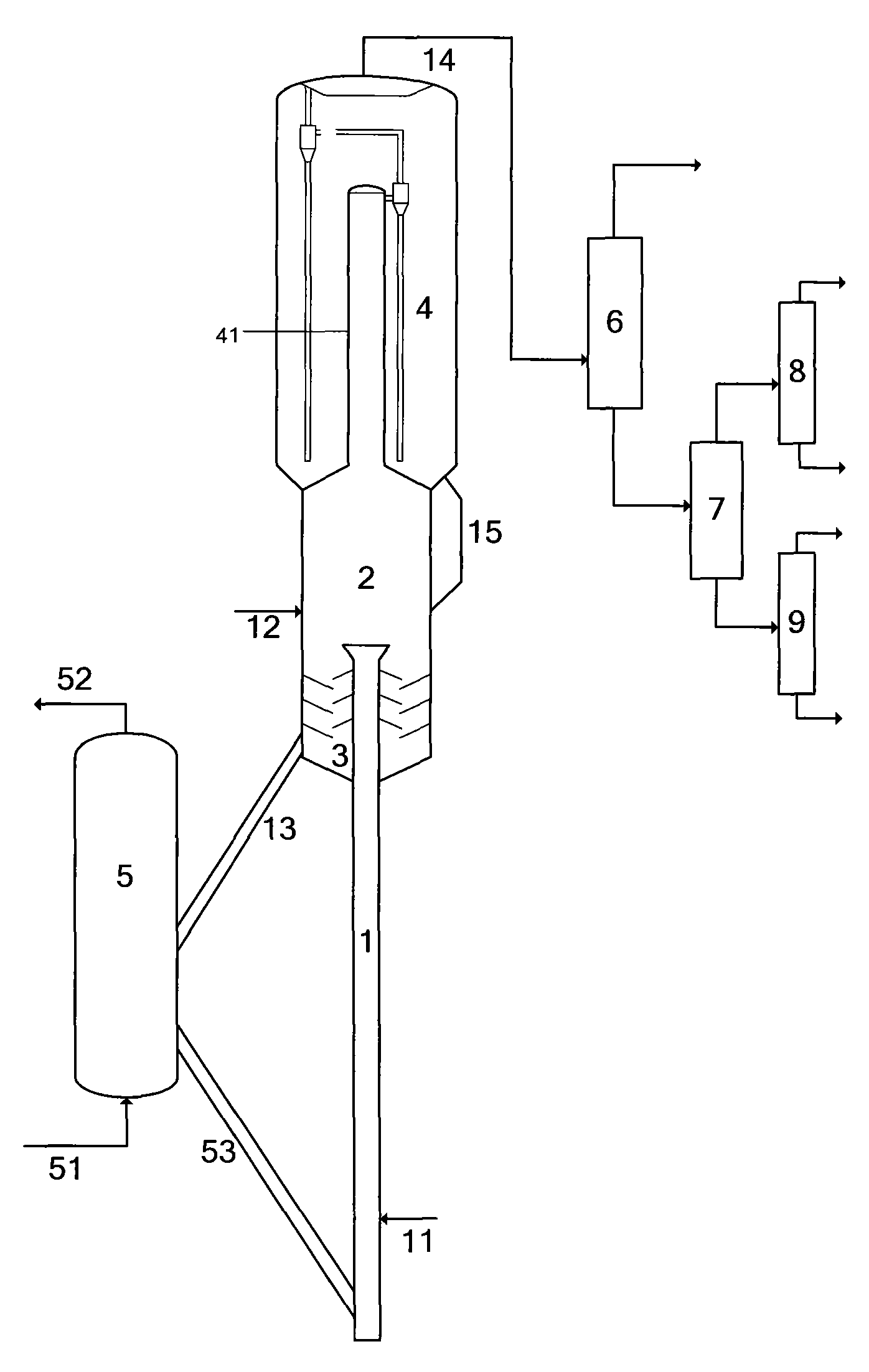

Method for preparing propylene through catalytic conversion of olefin raw material

A technology for catalytic conversion and raw materials, applied in catalytic cracking, hydrocarbon cracking to hydrocarbon production, and cracking, etc., can solve the problems of lower catalyst mass concentration, high oil contact temperature, lower reaction temperature, etc., and achieve shortened residence time and oil contact. The effect of low temperature and reduced dry gas yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Take ZSP molecular sieve, kaolin, rentalite and pseudoboehmite according to the proportion, add decationized water and aluminum sol and beat for 120 minutes, and the pH value of the slurry is 3.0. The mixture was further beaten for 45 minutes, and then the resulting slurry was spray-dried at an inlet temperature of 500° C. and an exhaust gas temperature of 180° C. to obtain microspheres with an average particle diameter of 65 μm. The microspheres were calcined at 500°C for 1 hour to obtain 35wt% ZSP molecular sieve, 45wt% kaolin, 20wt% Al 2 o 3 The microsphere catalyst A.

[0045] Catalysts B-J were prepared according to the above method, and the compositions of the catalysts are shown in Table 1. The catalyst added with rectorite is finally calcined at 500-600° C. for 3-6 hours.

[0046] Table 1 Composition of Catalysts A-J

[0047] catalyst Molecular sieve type and content, wt% Kaolin, wt% Alumina, wt% ZSP molecular sieve silicon aluminum ratio ...

Embodiment 2~10

[0052] Examples 2-10 illustrate the effects of using the catalytic conversion method for raw materials rich in C4-C8 olefins provided by the present invention.

[0053] The catalyst was aged at 760°C with 100% steam for 10 hours, using a medium-scale test device, in which the inner diameter of the riser reactor was 18 mm and the height was 6 meters, and the inner diameter of the fluidized bed reactor was 64 mm and the height was 0.5 meters , the inner diameter of the dilute phase pipe at the outlet of the fluidized bed reactor is 30% of the inner diameter of the fluidized bed reactor. The loading capacity of catalyst in the compound reactor is 60 kilograms. The olefin raw material is sprayed into the fluidized bed reactor, which is mainly composed of 3.67wt% butane and 96.33wt% butene. The riser is used to convey the regenerated catalyst.

[0054] Reaction conditions and results are shown in Table 3-Table 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com