Saline treatment system and method

A treatment system and brine technology, applied in the field of water treatment, can solve the problems of low evaporation efficiency, small steam output, environmental hazards, etc., and achieve the effects of improving evaporation efficiency, reducing equipment investment, and increasing water yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

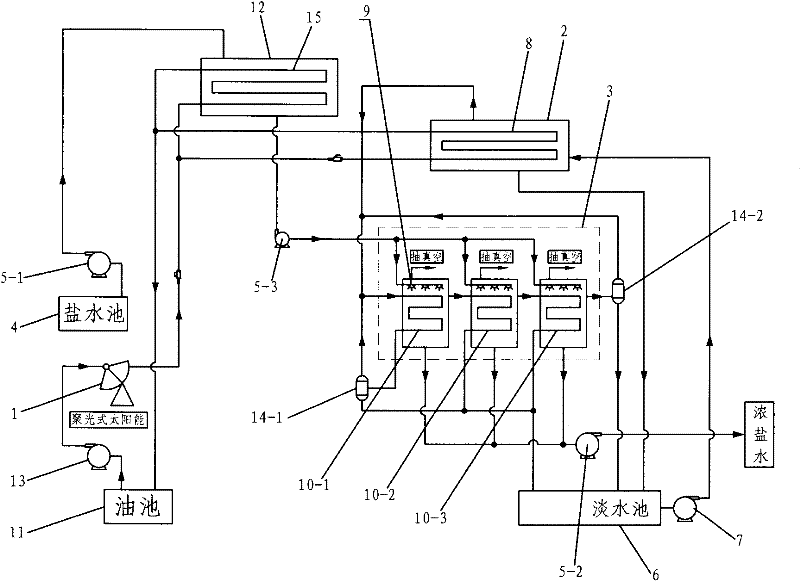

[0051] The brine treatment system of the present embodiment is as figure 1 As shown, it includes a concentrating solar heater 1, a steam generator 2, a vacuum multi-effect distillation device 3, a steam pipeline, a brine pool 4, a brine pipeline, a first brine pump 5-1, a fresh water pool 6, and a fresh water pipe road and fresh water pump7. The steam generator 2 contains a fresh water tank, a first heat exchanger 8 placed in the fresh water tank and a steam chamber, and the water inlet of the fresh water tank (that is, the water inlet of the steam generator 2) is connected to the fresh water tank through a fresh water pipeline and a fresh water pump 7 6 outlets. The vacuum multi-effect distillation device 3 is mainly composed of the same three distillation units connected in series, and each distillation unit includes a shower head 9, a heat exchange evaporator, a distillation chamber, a first brine tank and a second brine pump 5-2, The brine outlet of the vacuum multiple-e...

Embodiment 2

[0061] The brine treatment system of the present embodiment is an improvement on the basis of the first brine treatment system, such as figure 2 As shown, except that it is the same as Embodiment 1, the difference is that it also includes an energy storage oil pool 16 and an energy storage oil pump 17, and the oil outlet of the energy storage oil pool 16 is respectively connected to the first oil pump through the oil pipeline and the energy storage oil pump 17. The oil inlet of the heat exchanger 8 and the second heat exchanger 15, the oil inlet of the energy storage oil pool 16 are connected to the oil outlet of the concentrating solar heater 1 through the oil pipeline.

[0062] The salt water treatment method of this embodiment is an improvement on the basis of the salt water treatment method of Embodiment 1, except that it is the same as Embodiment 1. The difference is: using the salt water treatment system of this embodiment, in step 1), when When the concentrating solar ...

Embodiment 3

[0064] The brine treatment system of the present embodiment is an improvement on the basis of the first brine treatment system, such as image 3 As shown, except that it is the same as Embodiment 1, the difference is: it also includes a vacuum spray evaporation device 18, and the vacuum spray evaporation device 18 contains a spray nozzle 19, an evaporator 20, an evaporation chamber, the third brine tank and the fourth brine pump 5 -4. The steam outlet of the steam chamber of the steam generator 2 is connected to the steam inlet of the evaporator 20 through a steam pipeline, and the steam outlet of the evaporator 20 is connected to the inlet of the first steam-water separator 14-1 through a steam pipeline. Steam port, the steam outlet of the evaporation chamber of the vacuum spray evaporation device 18 is connected to the steam inlet of the first heat exchange evaporator 10-1 of the vacuum multiple-effect distillation device 3 through a steam pipeline; the brine outlet of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com