Filter tower

A filter tower and filter technology, applied in the field of filter towers, can solve the problems of dirty cooling water, poor cooling effect, inconvenient production, etc., and achieve the effect of saving water and reducing maintenance workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

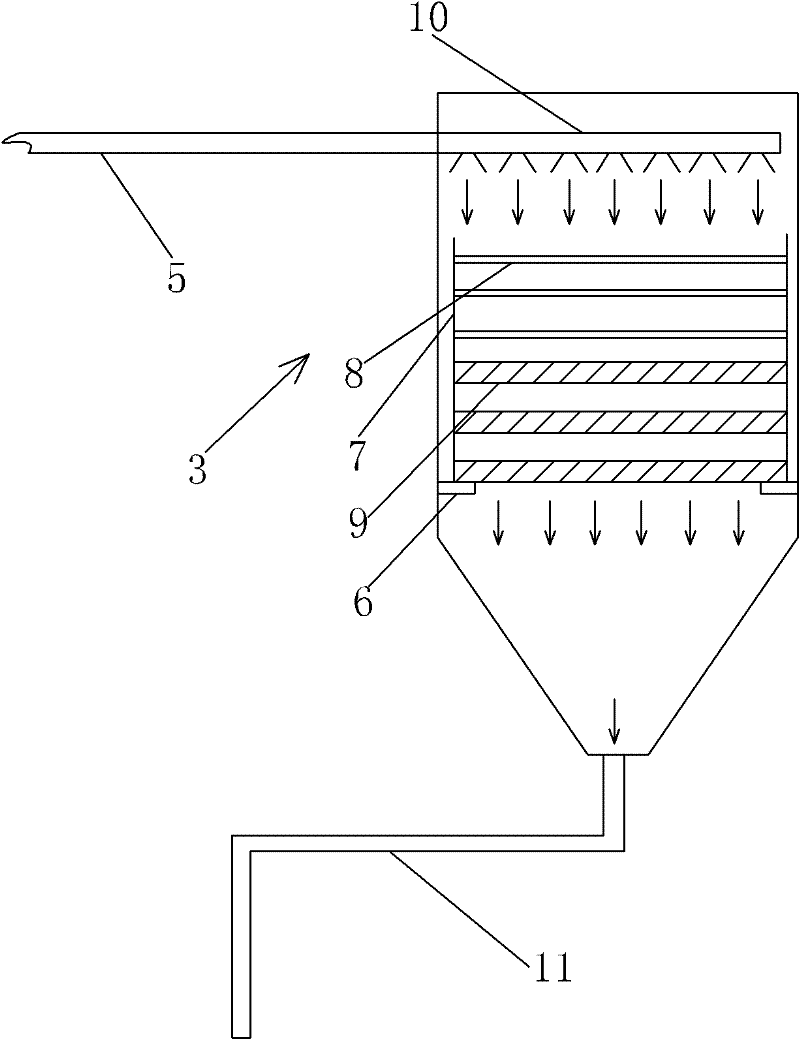

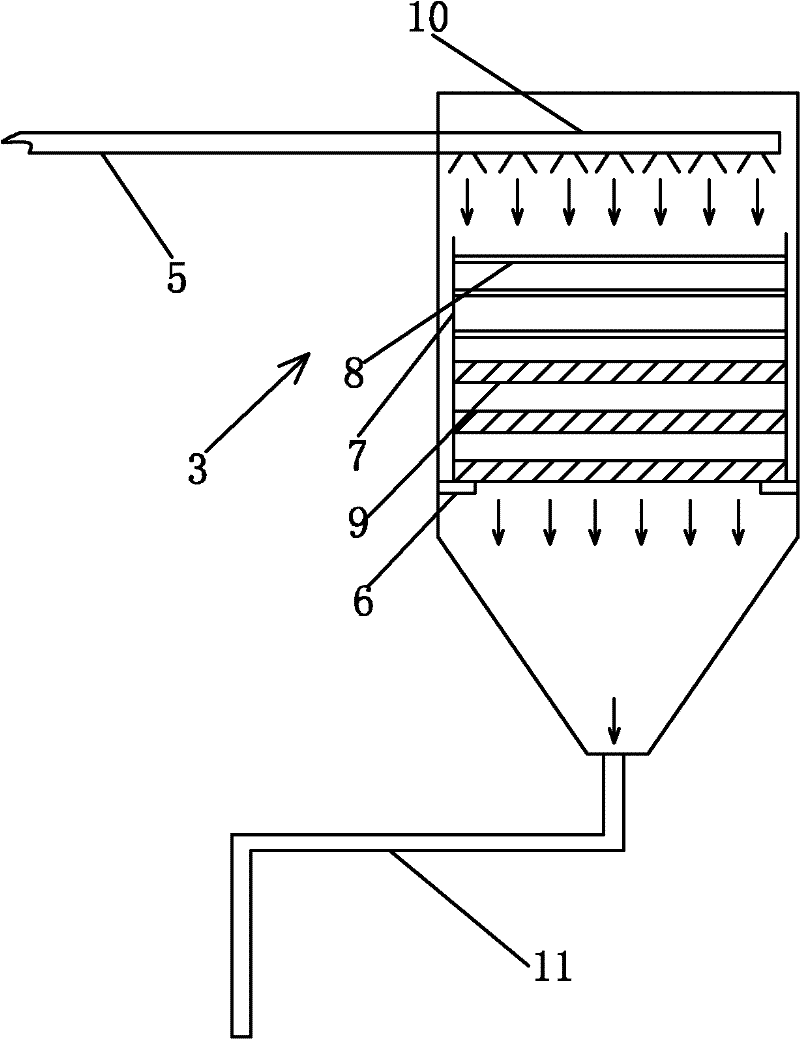

[0016] Embodiment: a kind of filter tower, as figure 1 As shown, a filter is provided in the filter tower 3, and a support plate 6 for placing the filter is provided on the inner wall of the filter tower 3, and the filter is placed on the support plate 6, and the support plate 6 is an annular flat plate .

[0017] Described filter comprises the filter body 7 that is cylindrical, and filter body 7 opens up and down, is provided with a plurality of filter layers from top to bottom in filter body 7, and described filter layer is made of filter net 8 and The non-woven cotton filter layer 9 is composed of; the filter screen 8 is 3 layers, and the non-woven cotton filter layer 9 is 3 layers, and the filter screen 8 and the non-woven cotton filter layer 9 are respectively arranged on the filter body 7 Half and lower half, and the aperture of filter screen 8 gradually becomes smaller from top to bottom.

[0018] A spray pipe 10 is horizontally arranged above the filter, and the spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com