A kind of label paper and label paper production equipment

A technology for production equipment and label paper, applied in the field of label paper and label paper production equipment, can solve the problems of downward overflow of adhesive, affecting the effect of label paper gluing, uneven adhesive, etc. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

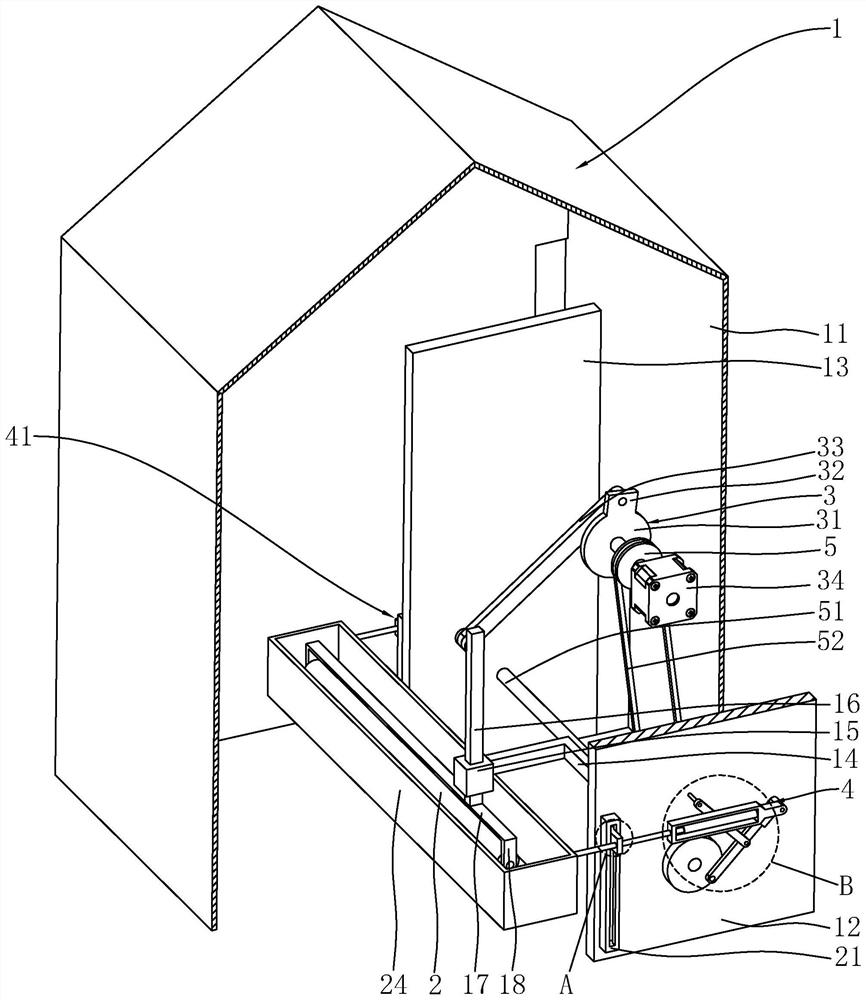

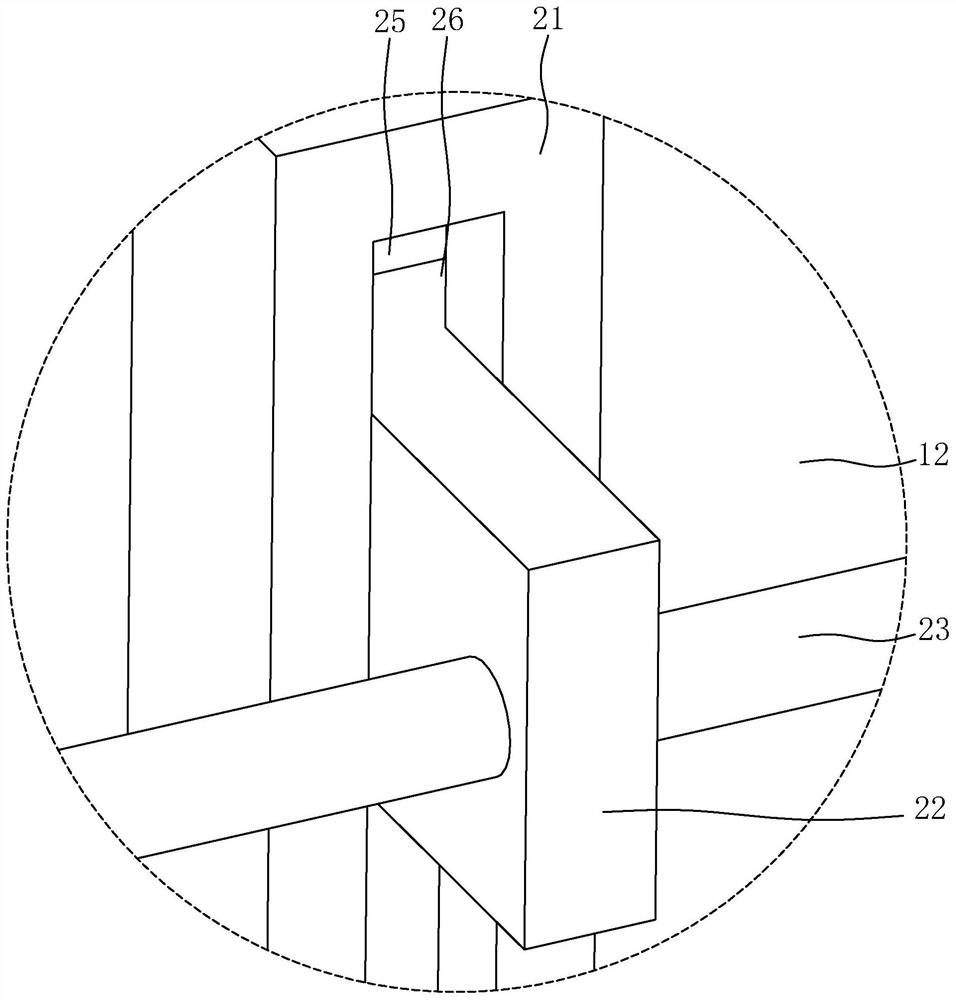

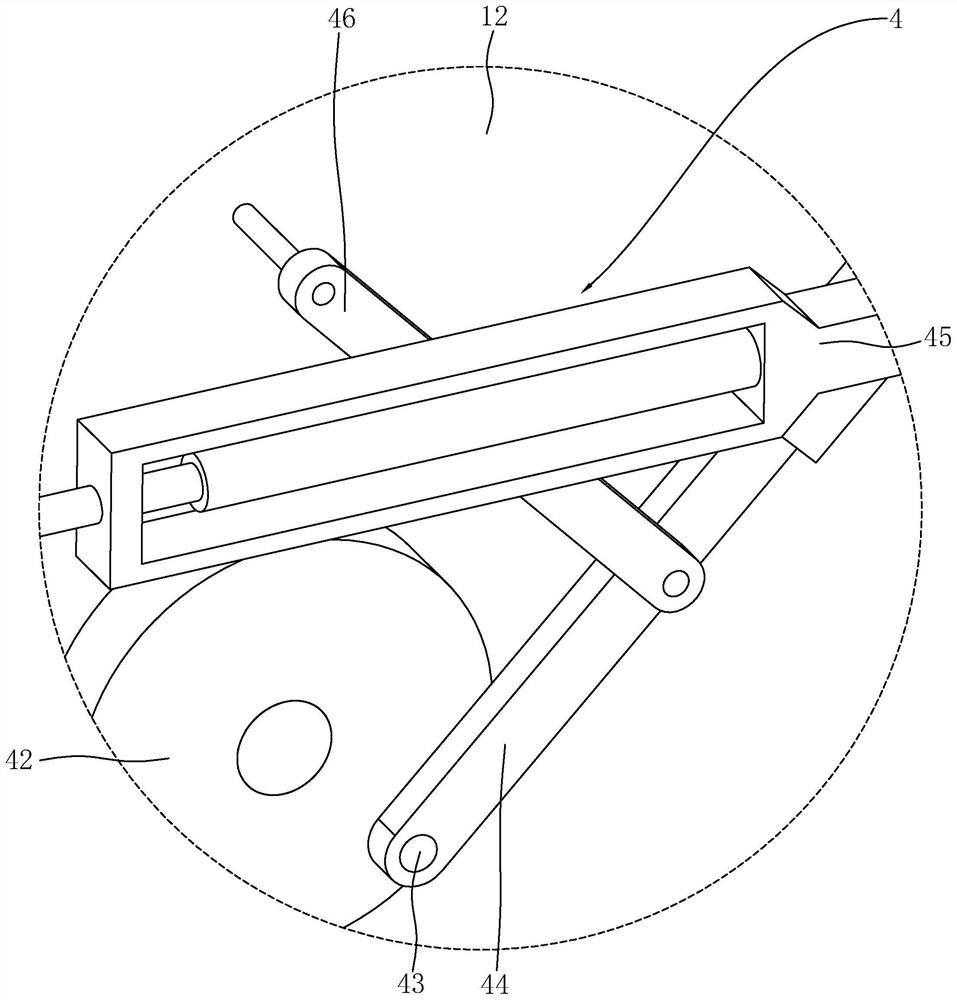

[0033] The following is attached Figure 1-3 The application is described in further detail.

[0034] The embodiment of the present application discloses a label paper and label paper production equipment. The label paper includes a paper layer, an adhesive layer coated on the surface of the paper layer, and a surface layer adhered to the top surface of the paper layer through the adhesive layer. The paper layer is release paper. The surface layer is aluminized polyethylene terephthalate film. The adhesive layer is an acrylic adhesive. After the surface layer is glued, it is laminated with the paper layer to form a label paper.

[0035] refer to figure 1 , figure 2 , the label paper production equipment includes a gluing device 1 , and the gluing device 1 includes an outer shell 11 , a first fixing plate 12 and a second fixing plate 13 fixed on the inner side of the outer shell 11 . A support rod 14 is fixed on one side of the first fixing plate 12 , and a square tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com