Resin composition for cleaning of resin molding machines

A resin composition, resin molding technology, applied in the directions of organic cleaning compositions, detergent compositions, cleaning composition dyes, etc., can solve problems such as a large amount of resin, long time, etc., and achieve easy confirmation, shortening time, and shortening cleaning time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Using an injection molding machine ("Mitsubishi Injection Molding Machine 265 / 100MSII" manufactured by Mitsubishi Heavy Industries, Ltd.), 1 kg of ABS resin was injected and molded at a molding temperature of 230°C. The composition of Example 1 (with tracer substance) shown in Table 1 was then injected.

[0039] Then, POM colored black (manufactured by Polyplastic Corporation, DURACON M90-44) was charged into the injection molding machine, and a test molded product (100 mm×100 mm×3 mm) was molded.

[0040] After the start of molding, the cleaning resin composition of Example 1 was visible to the naked eye in the first and second test molded articles, and the cleaning resin composition of Example 1 was not mixed in the third test molded article. When it is irradiated with UV light (wavelength 365nm) at this time, since a part of it emits light ( figure 1 ), it was confirmed that the resin composition for cleaning of Example 1 was mixed (that is, the resin composition fo...

Embodiment 2

[0043] The same test as in Example 1 was carried out using the composition of Example 2 shown in Table 1 (containing a tracer substance). As a result, no light emission was confirmed when the 15th test molded product was molded, so it was judged that the cleaning resin composition of Example 2 did not remain in the injection molding machine at this time.

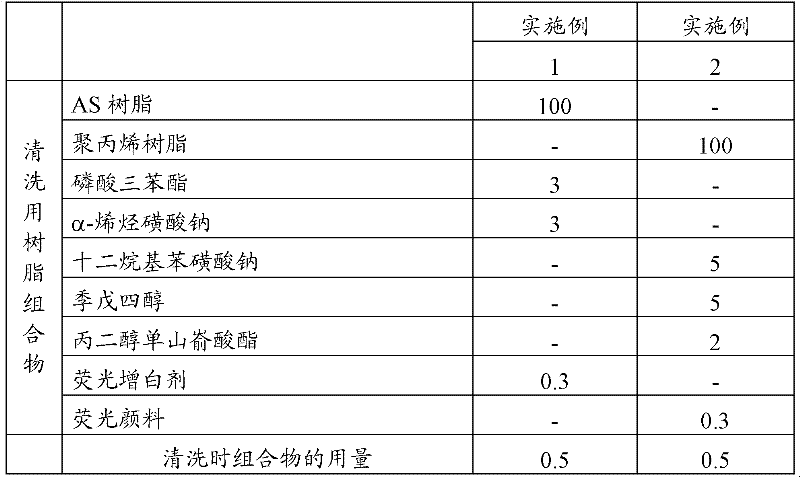

[0044] Table 1

[0045]

[0046]The values in Table 1 are expressed in kg.

[0047] AS resin: Cevian N080SF manufactured by Daicel Polymer Co., Ltd.

[0048] Polypropylene resin: Prime Polypro F-300SP manufactured by Prime Polymer Co., Ltd. (melt flow rate 3 g / 10 minutes (230° C. / 2.16 kg)

[0049] Fluorescent pigment: DAYGLO LFY (AR Brown company)

[0050] Optical brightener: Hostalux KS1 (manufactured by Clariant)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com