Steering controller of high-power direct-current motor

A steering controller, DC motor technology, applied in the direction of a single DC motor starter, motor generator/starter, etc., can solve the problem of not suitable for high-power DC motor drive control, limited output power of DC motor drivers, and difficult to apply High reliability field and other problems, to achieve the effect of stable work, fast action speed and little interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

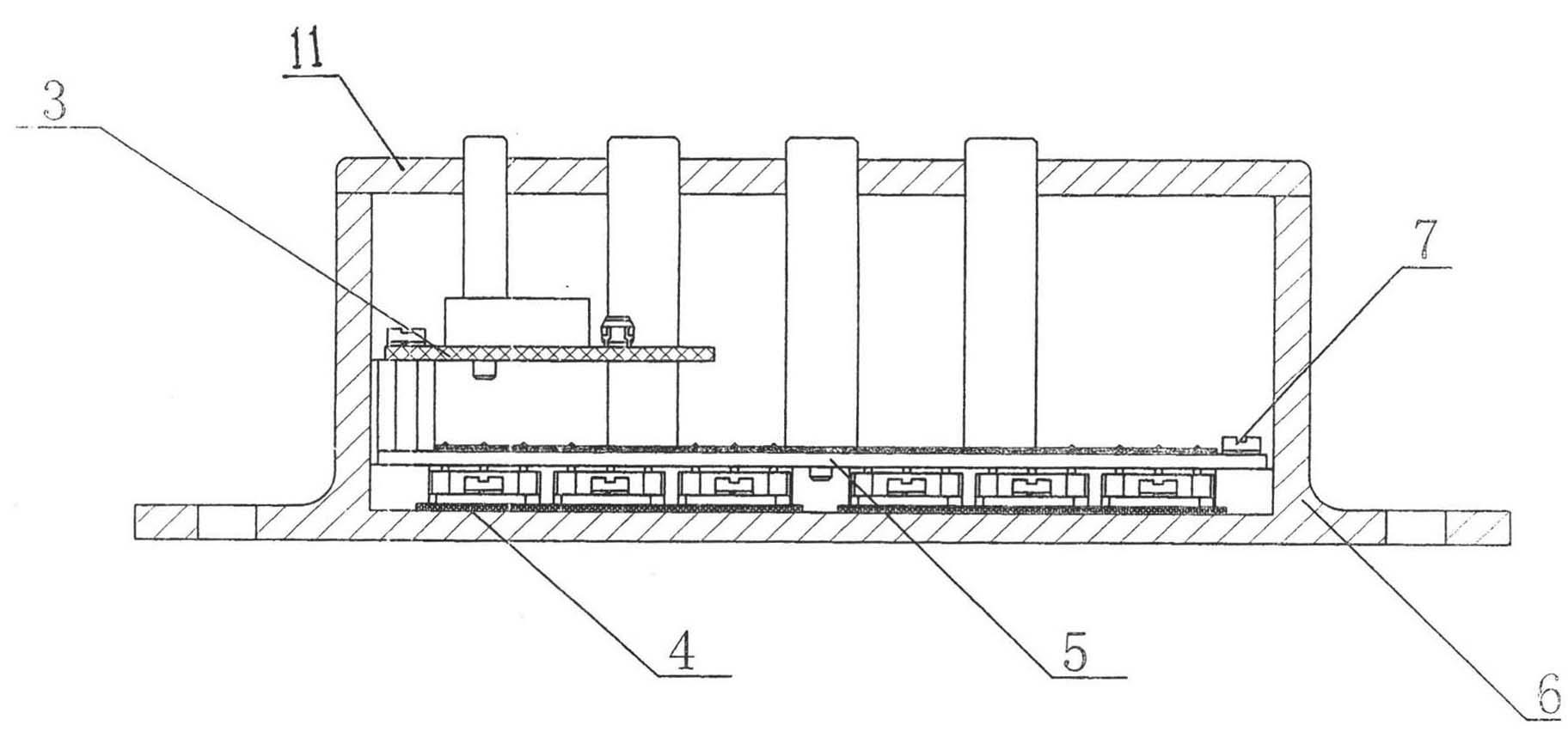

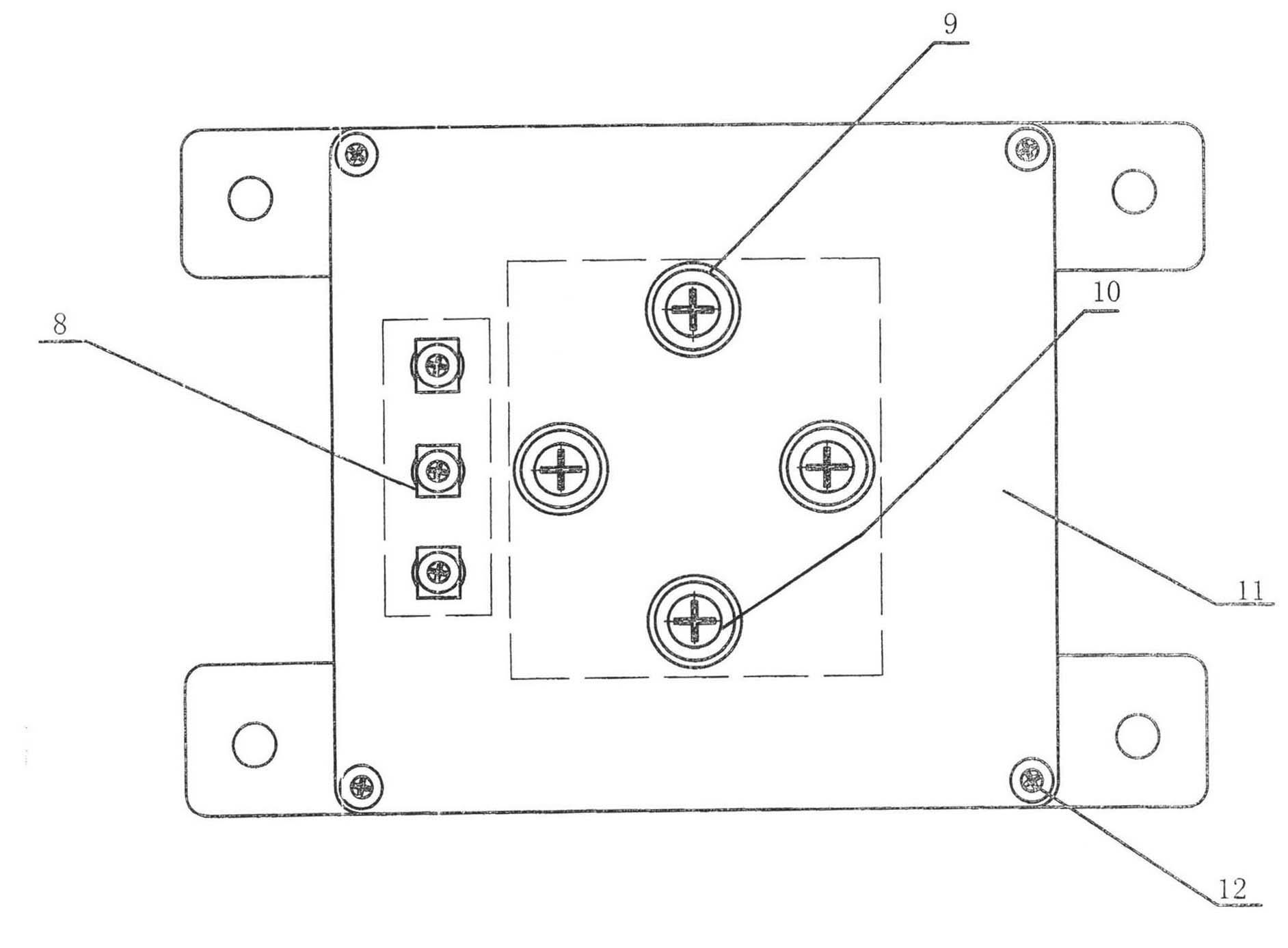

[0019] combined with figure 1 , 2 , 3, 4 describe an embodiment of the present invention.

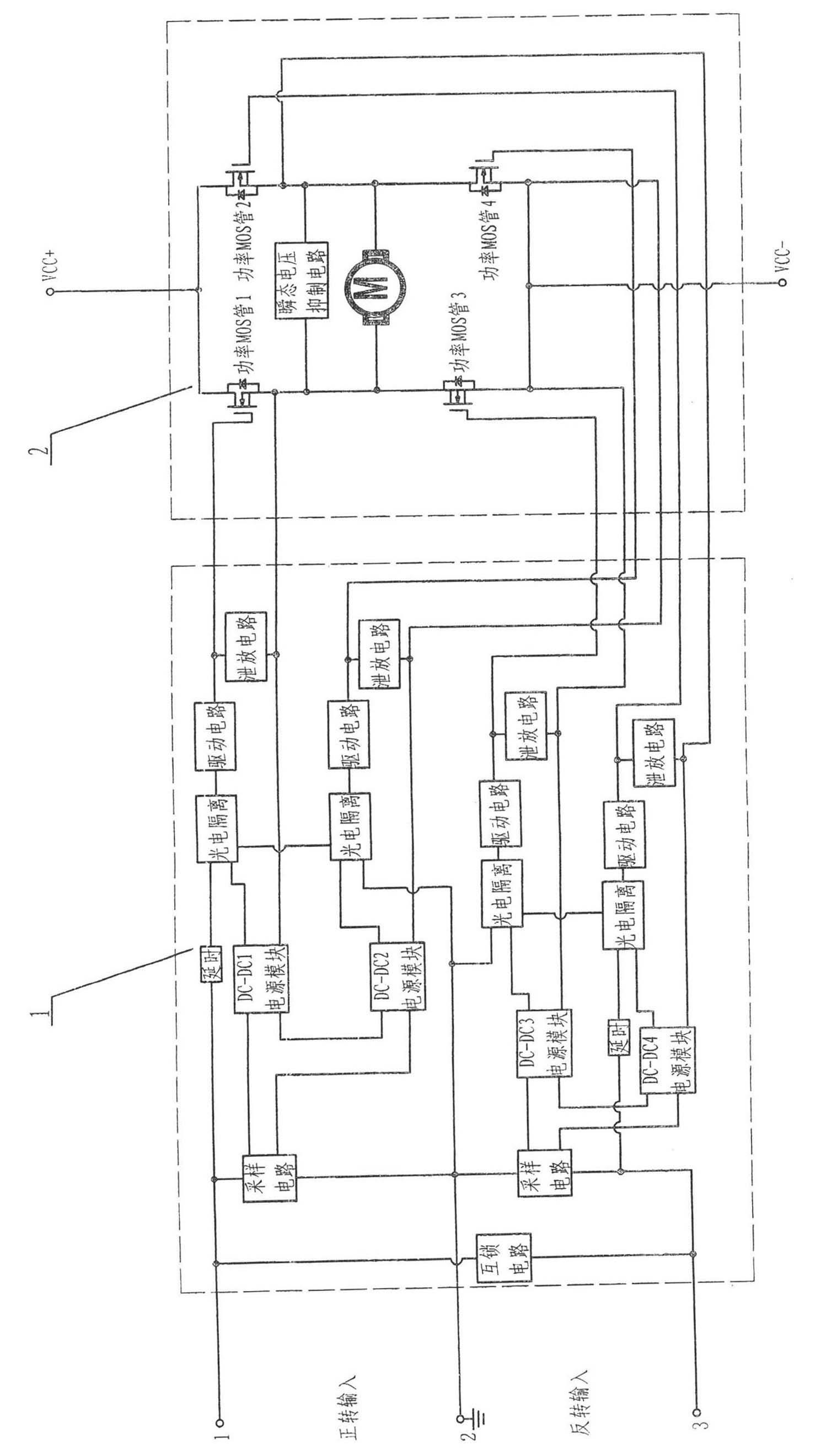

[0020] A high-power DC motor steering controller is composed of an input control module 1 and a power output control module 2; the input control module 1 includes a forward rotation input control circuit and a reverse rotation input control circuit, and the power output control module 2 is composed of Four power MOS tubes are connected in parallel to form four sets of normally open contacts, and four sets of normally open contacts form an H-bridge control circuit; the forward rotation input control circuit includes two circuits, and the reverse input control circuit also includes two circuits; each circuit includes DC-DC power supply module, delay circuit, photoelectric isolation circuit and drive circuit. The DC-DC power supply module boosts the input control signal and sends it to the input terminal of the photoelectric isolation circuit. After the photoelectric isolation circuit is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com