Continuous technological process for producing calcium sulfate whiskers on a large scale

A technology of calcium sulfate whiskers and process methods, which is applied in the field of producing calcium sulfate whiskers, and can solve problems such as large fluctuations in whisker length-to-diameter ratio in intermittent operation cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

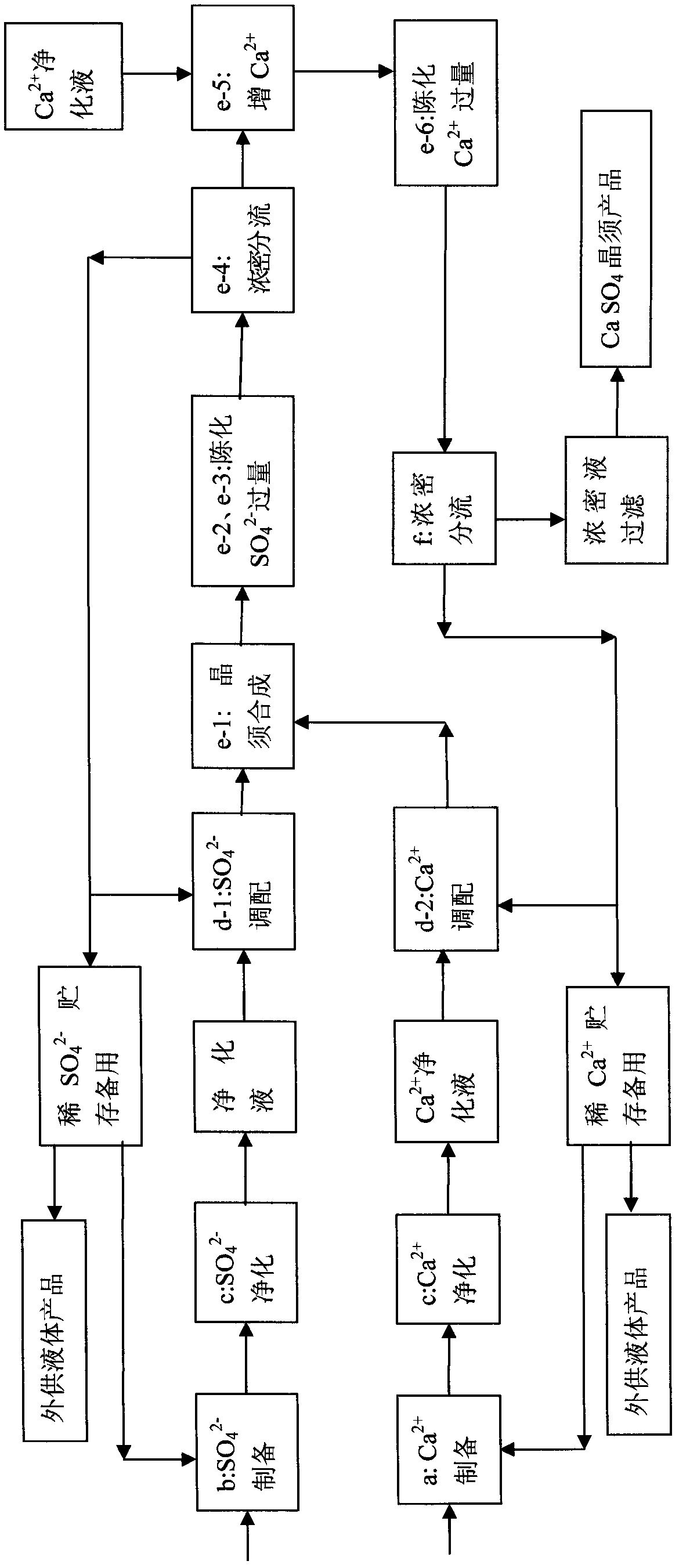

[0056] The technical scheme that the present invention takes comprises the following steps:

[0057] a, the preparation contains water-soluble Ca 2+ solution; in this step in continuous production, there are two main guarantees, one is to dissolve Ca 2+ The solution does not contain SO 4 2- Ions, the present invention is to use the stored Ca 2+ prepared from a dilute solution; the second is the water-soluble Ca 2+ The source of the solution will ensure that the preferred raw materials of the present invention all meet the needs of large-scale industrial production. The preferred water-soluble Ca of the present invention 2+ The solution consists of:

[0058] 1) Use HCl, HNO 3 、H 3 PO 4 Or its mixed acid in any proportion, decompose phosphorus-containing minerals to prepare water-soluble Ca 2+ The solution;

[0059] 2) Water-soluble CaCl containing NaCl discharged by ammonia-alkali process 2 ;

[0060] 3) Water-soluble Ca prepared by reacting waste acid in the pickl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com