Ablation carbon layer surface temperature measurement control method and device

A surface temperature, measurement and control technology, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problems of deviation of high-temperature thermal radiation test results of ablated carbon layer, poor internal heat conduction performance, etc. Effects of improved control accuracy and improved surface temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

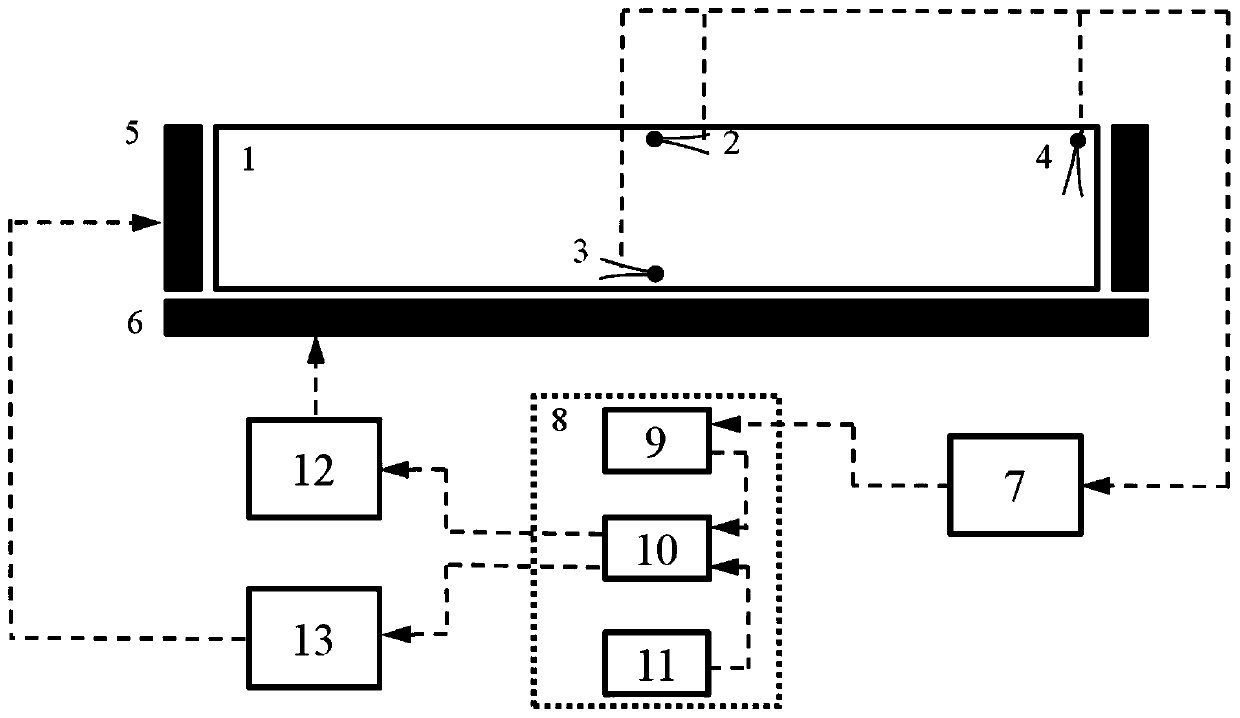

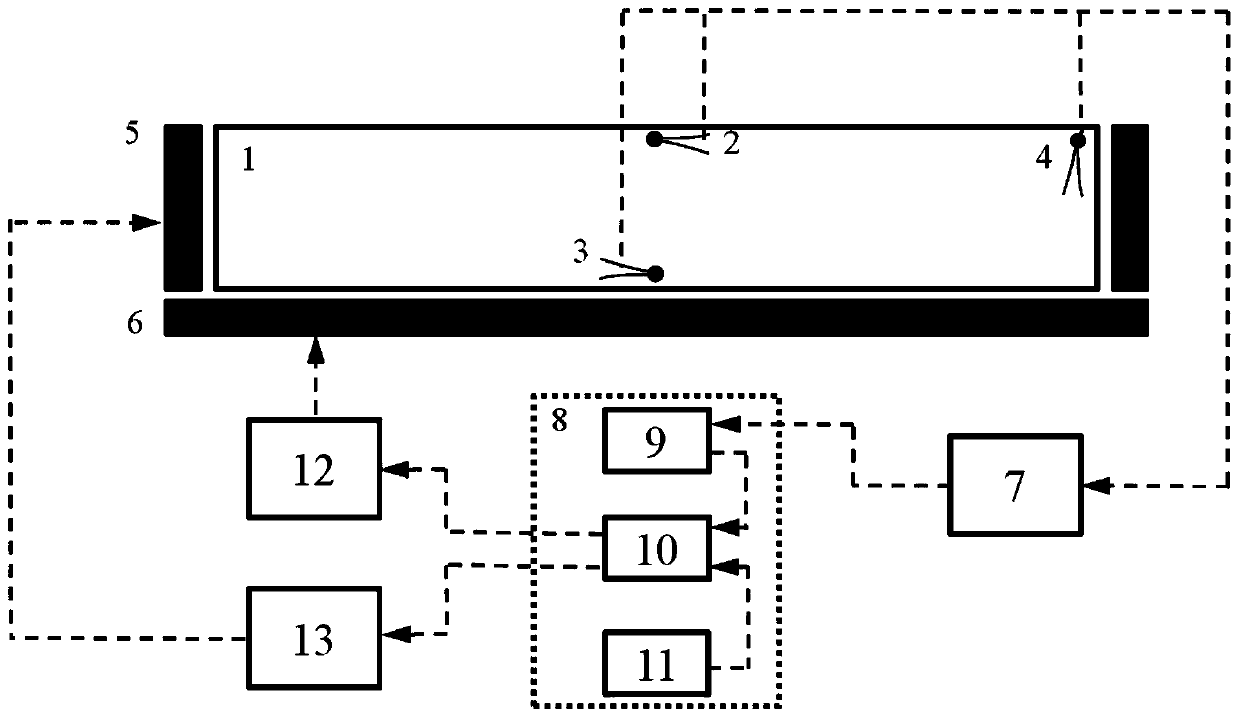

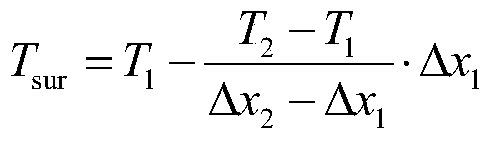

[0057] Such as figure 1 As shown, a device for measuring and controlling the surface temperature of the ablated carbon layer proposed by the present invention includes a sample 1 of the ablated carbon layer, a heating system, a temperature acquisition system, and a data processing and control system 8 . The ablation carbon layer sample 1 is in the shape of a thin cylinder. The plane heater 6 and the annular heater 5 in the heating system heat the ablation carbon layer sample 1 according to the specified heating power. The temperature measuring thermocouple inside the carbon etched layer sample 1 collects the real-time temperature data of a specific position inside the ablated carbon layer sample 1 and transmits it to the data processing and control system 8. The data processing and control system 8 calculates the ablation rate according to the real-time temperature data. The surface temperature of the carbon layer sample 1, and control the heating power of the heating system a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com