Microbial fermentation enzymolysis method for extracting grease and protein of soybean

A technology of microbial fermentation and soybean oil, which is applied in the extraction of soybean oil and protein, and in the field of soybean oil and protein extraction through microbial fermentation liquid enzymolysis, which can solve the problem of increasing the complexity of the process, not getting rid of the use of organic solvents, and the actual yield is low problems such as reducing the workload of water washing to remove salt, reducing the workload of process operations, and reducing the use of alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

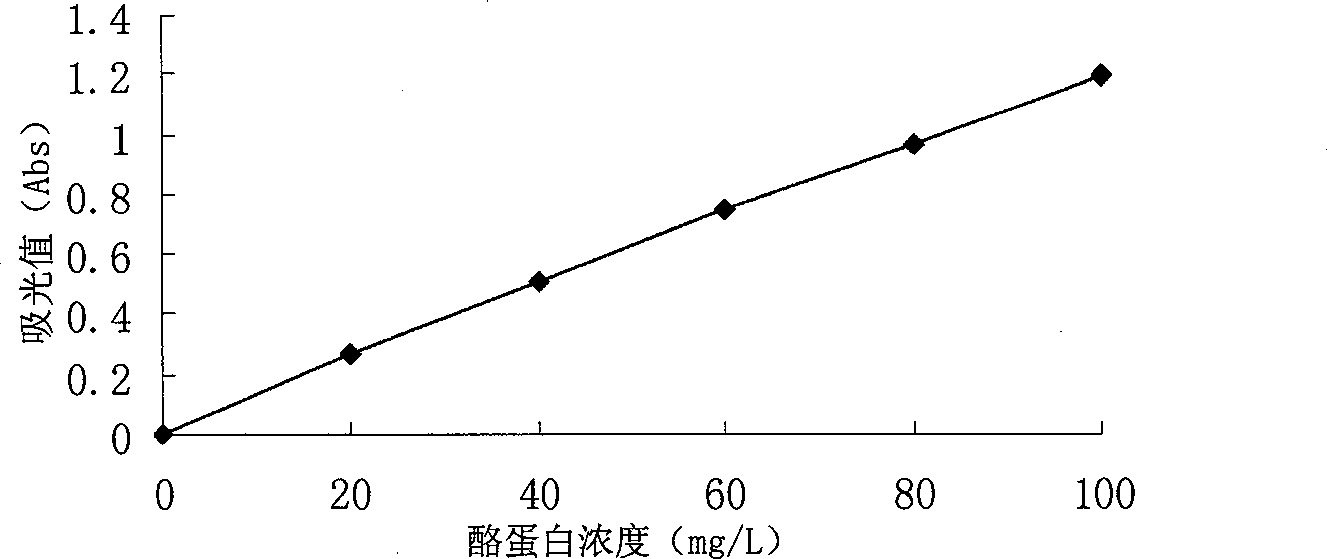

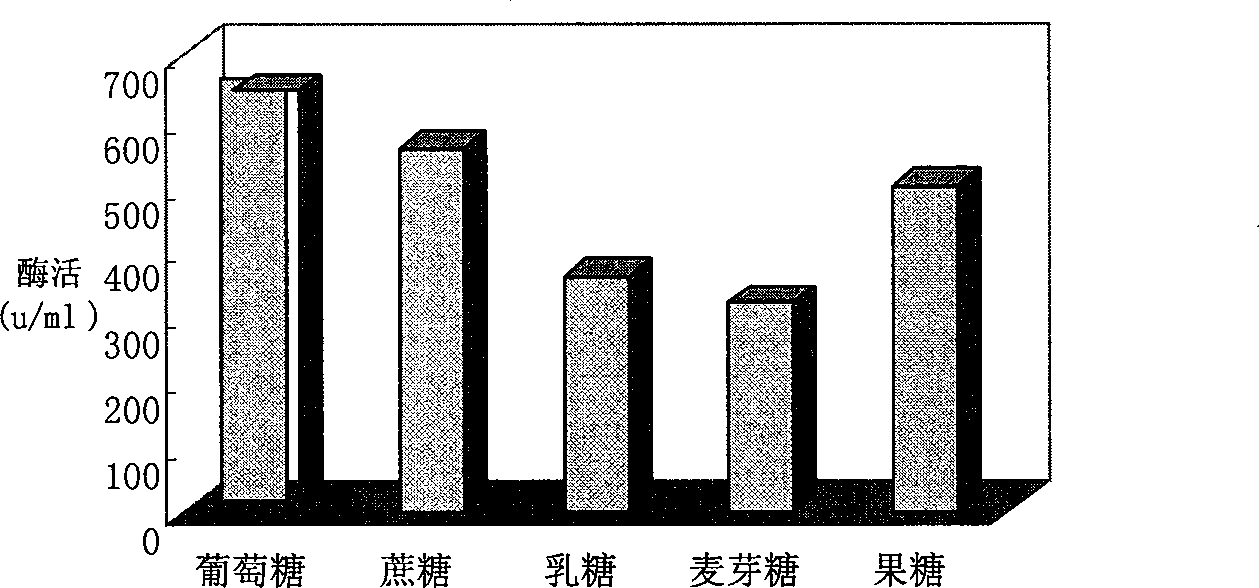

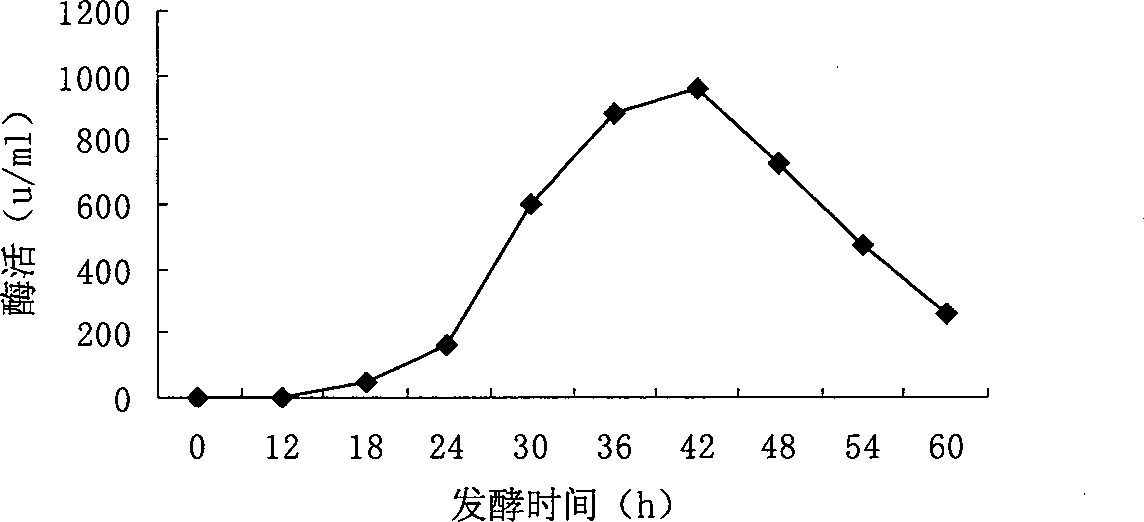

[0053] Experimental example 1 Composition of liquid fermentation medium and optimization experiment of fermentation conditions

[0054] 1 Materials and methods

[0055] 1.1 Experimental materials

[0056] 1.1.1 Strains

[0057] Bacillus subtilis was purchased from China Industrial Microorganism Culture Collection Center (ATCC20524).

[0058] 1.1.2 Reagents

[0059] Beef extract, peptone, glucose, soluble starch, maltose, sucrose, tyrosine, folin phenol reagent, trichloroacetic acid, anhydrous sodium carbonate, and sodium chloride are all analytically pure; Tris-Hcl buffer solution (pH8. 9 is suitable for the determination of alkaline protease activity, pH 7.2 is suitable for the determination of neutral protease activity).

[0060] 1.1.3 Raw materials

[0061] Low-temperature defatted soybean meal: purchased from Harbin Gaoke Biotechnology Company.

[0062] 1.1.4 Medium

[0063] Incline preservation medium: 1% peptone, 0.5% beef extract, 0.5% sodium chloride, 1.5% agar,...

experiment example 2

[0144] Experimental example 2 Process optimization experiment of enzymatic hydrolysis conditions and demulsification conditions

[0145] 1 Materials and methods

[0146] 1.1 Experimental materials

[0147] Raw materials: extruded soybeans.

[0148] 1.2 Extrusion and expansion: the moisture content of the material is 13%-17wt%, the sleeve temperature of the extrusion extruder is 85-110°C, and the screw speed is 95-115r / min.

[0149] 1.3 Crush: Crush the extruded material and pass it through a 70-120 mesh sieve.

[0150] 1.4 Experimental method

[0151] 1.4.1 Process flow

[0152] Such as Figure 19 shown.

[0153] 1.4.2 Test method:

[0154] Determination of protein content: Kjeldahl method

[0155] Determination of fat content in milk: Gothic-Ross method

[0156] Oil content in residue: Soxhlet extraction

[0157] 1.4.3 Test formula

[0158]

[0159]

[0160]

[0161]

[0162]

[0163]

[0164] 1.4.4 Determination of the process conditions for extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com