Method for recovering strontium slag

A technology of strontium slag and ph value, which is applied in the field of recovery of leaching residues, can solve the problems of increasing production costs and resource waste, and achieve the effect of improving recovery rate and resource utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

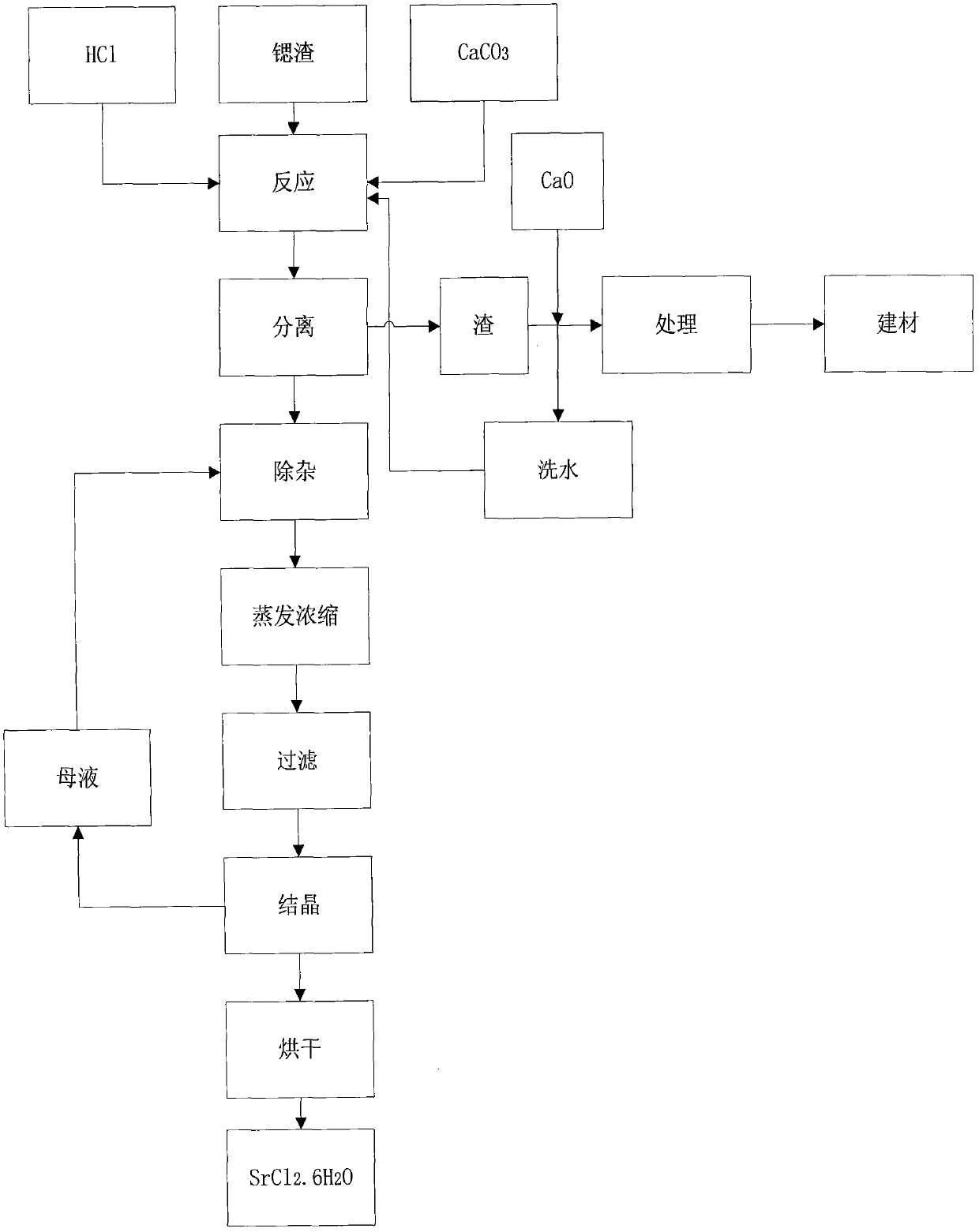

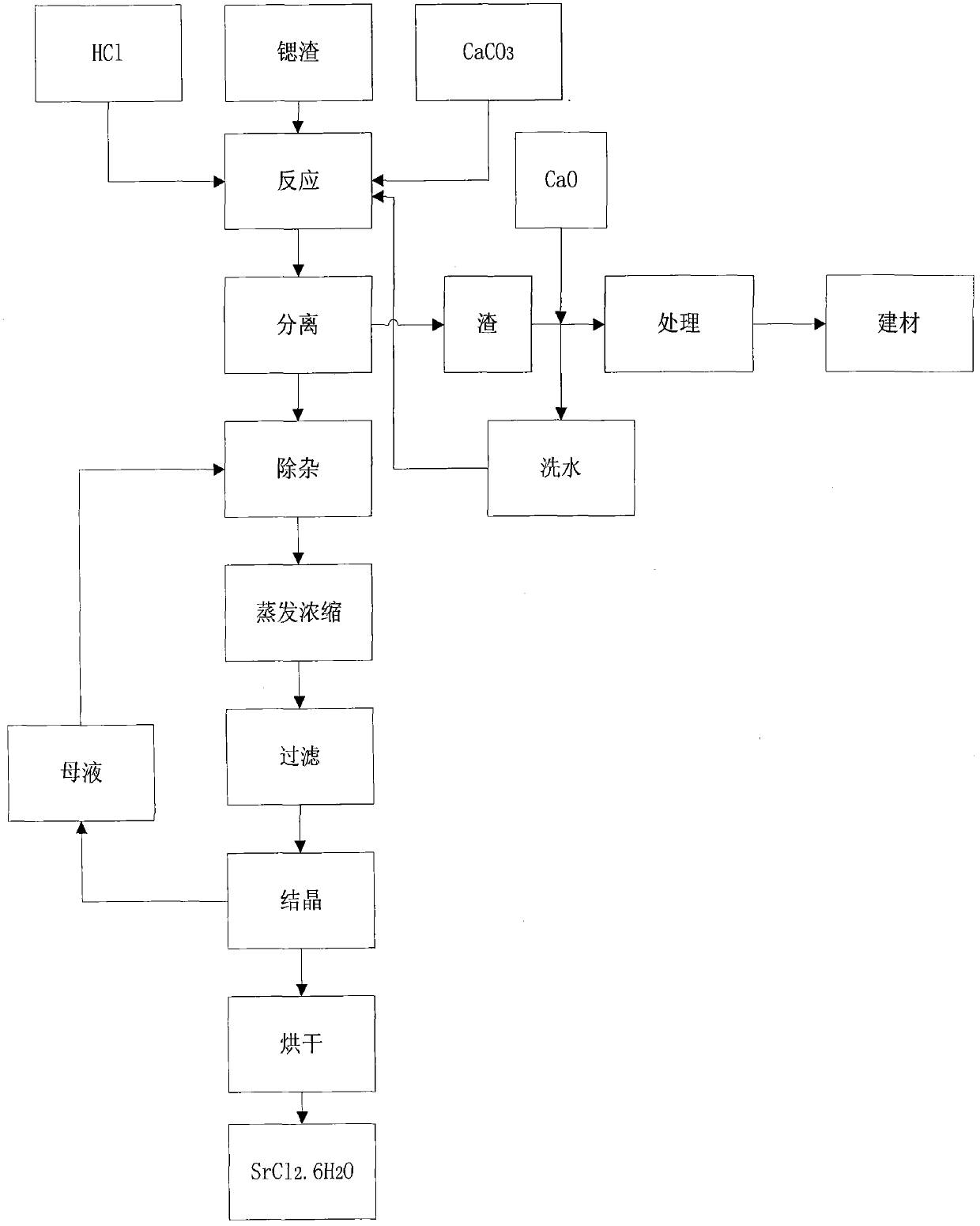

Method used

Image

Examples

Embodiment 1

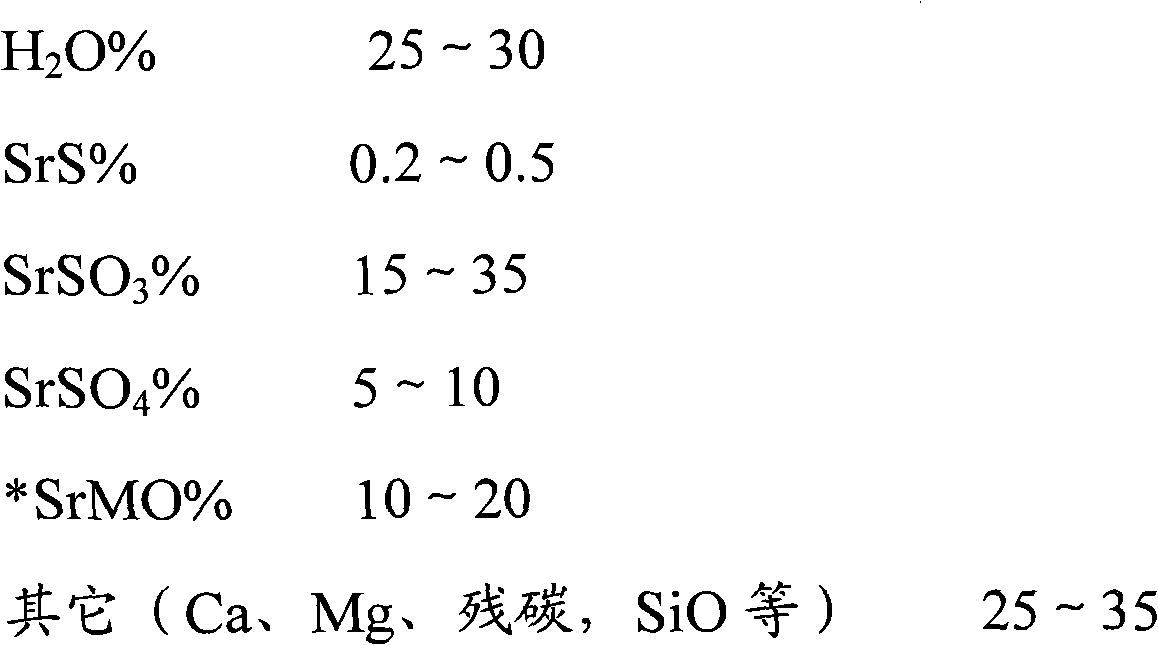

[0051] Strontium-containing leaching residue 3.0Kg (water content 27.4%), measure all acid-soluble strontium (calculated as strontium chloride hexahydrate) to be 34.71%, add industrial hydrochloric acid to react to pH = 1 under stirring, add CaCO 3 Mineral powder (calcium carbonate content 85%) 170 grams, until utilize acid iodometric method to measure SO in real time in reaction 3 2- The concentration was 1.10g / L, and CaO was added to adjust the pH to 6, separated by suction filtration, the filter cake was rinsed with a small amount of deionized water, the filtrate was combined, and the filter residue was discarded.

[0052] Stir the above filtrate and add industrial hydrogen peroxide and strontium hydroxide, heat to boil, evaporate and concentrate, hot press filter, discard the filter residue, liquid phase cooling and crystallization, after drying, sample 1# is obtained, and the crystallization mother liquor is returned to add hydrogen peroxide and hydrogen The strontium ox...

Embodiment 2

[0054] Strontium-containing leaching residue 3.0Kg (moisture content 28.0%), measure all acid-soluble strontium (calculated as strontium chloride hexahydrate) to be 27.11%, add industrial hydrochloric acid to react to pH=2 under stirring, add CaCO 3 Mineral powder (calcium carbonate content 85%) 135 grams, until utilizing acid iodometric method to measure SO in real time in the reaction 3 2- The concentration is 0.83g / L, add CaO to adjust the pH value to 7, separate by suction filtration, rinse the filter cake with a small amount of deionized water, combine the filtrate, and then use CaO to adjust the pH value to 8. The filter cake can be used as a foundation For building materials, the washing water is returned to the acidification reaction for recycling.

[0055] Add industrial hydrogen peroxide and strontium hydroxide to the above filtrate under stirring, heat and boil, evaporate and concentrate, hot press filter, discard the filter residue, liquid phase cooling and crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com