Pneumatic tire

A pneumatic tire, tire circumferential technology, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problems of reducing the durability of pattern blocks, easy to generate cracks, poor grip, etc., to achieve Effects of suppressing cracks, alleviating stress concentration, and suppressing reduction in grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Next, embodiments of the present invention will be described in detail.

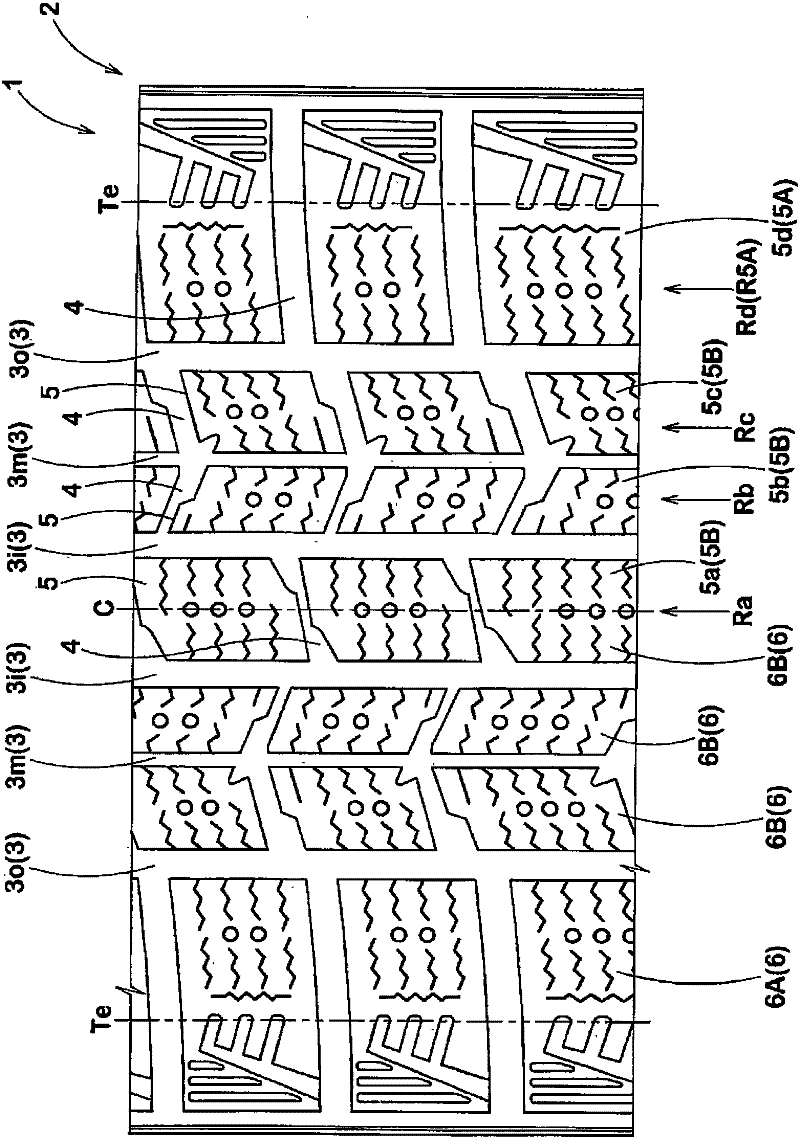

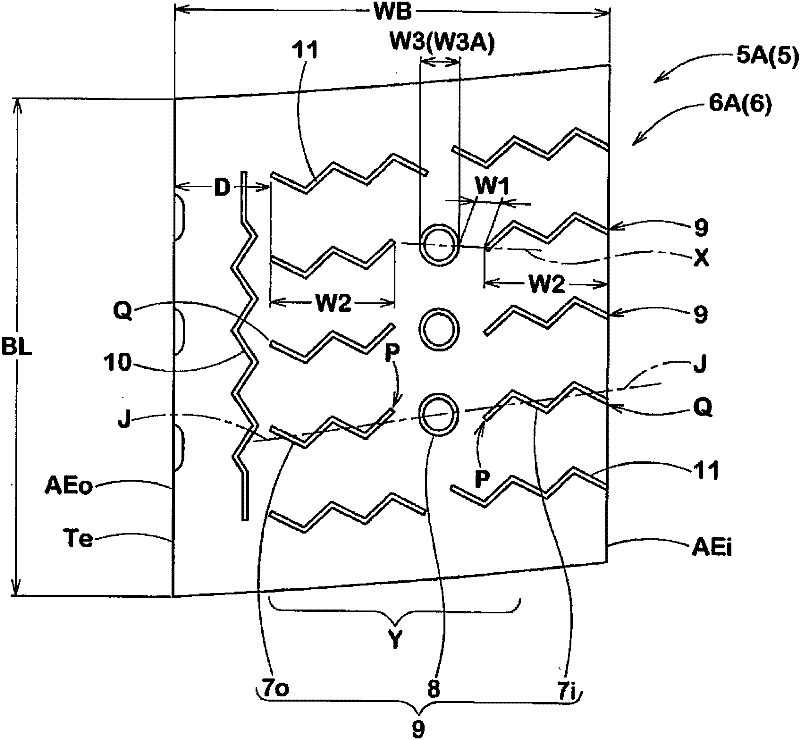

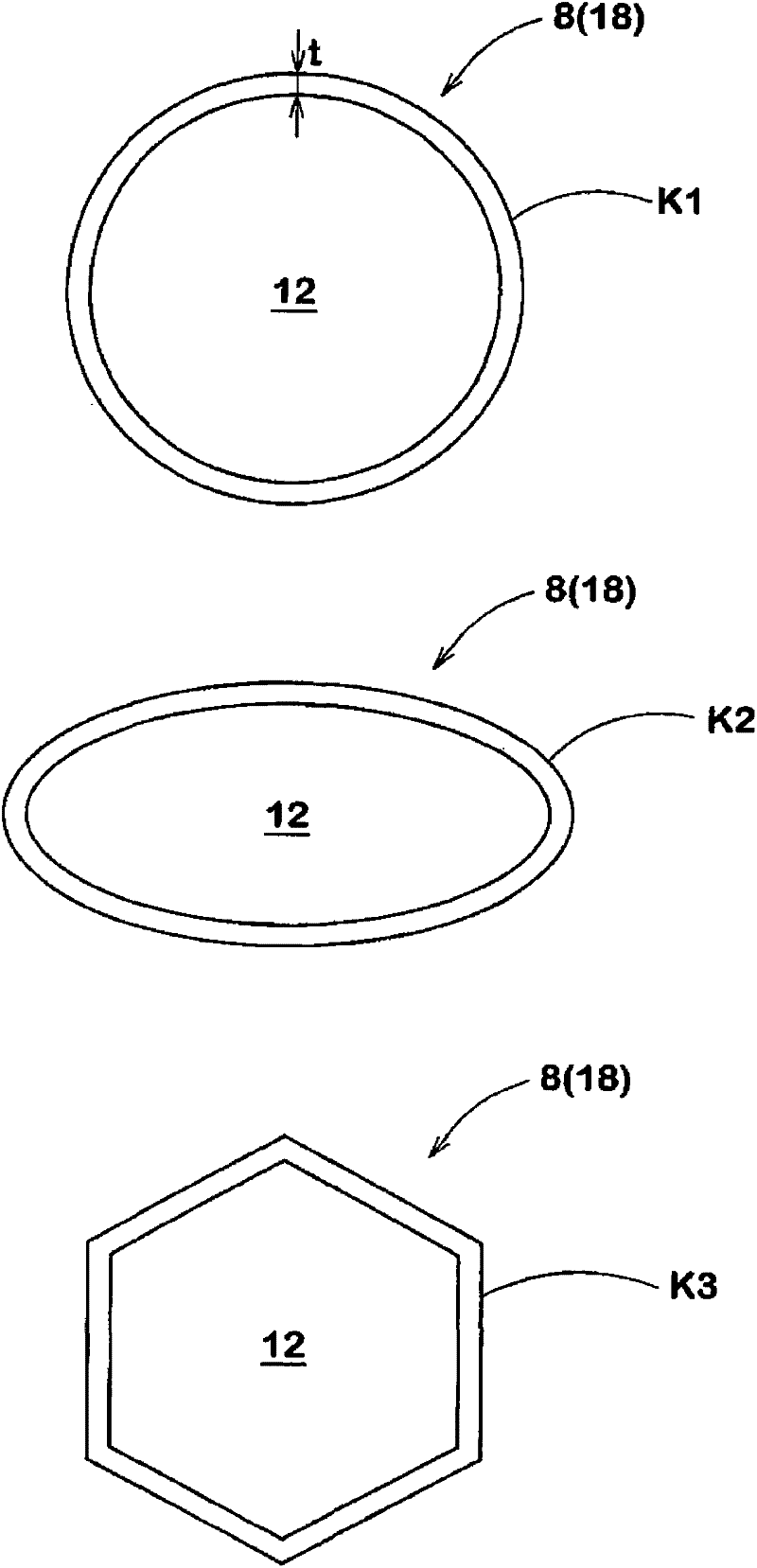

[0029] figure 1 In the pneumatic tire 1 of this embodiment, the tread portion 2 has a circumferential groove 3 extending in the tire circumferential direction, and between the circumferential grooves 3, 3 and / or between the circumferential groove 3 and the tread edge Te. The extended lateral groove 4 thereby forms a plurality of blocks 5 defined by the circumferential groove 3 and the lateral groove 4 , or the circumferential groove 3 and the tread edge Te and the lateral groove 4 in the tread portion 2 .

[0030] In addition, the plurality of blocks 5 include: a shoulder block 5A forming a shoulder block row R5A extending in the tire circumferential direction along the tread edge Te; The shoulder block 5A is closer to the inner side in the tire axial direction (the tire equator plane side).

[0031] Specifically, the pneumatic tire 1 of this example is formed with a total of six circumferentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com