Polysulfonamide fiber-containing dry mica tape and application thereof

A technology of polyaryl sulfone fiber and mica tape, which is applied in the direction of single-component copolyamide artificial filament, shape/style/structure of winding insulation, layered products, etc. Insufficient thermal mechanical properties of insulating structures, etc., to achieve excellent electrical insulation performance, improved air permeability, and improved thermal mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

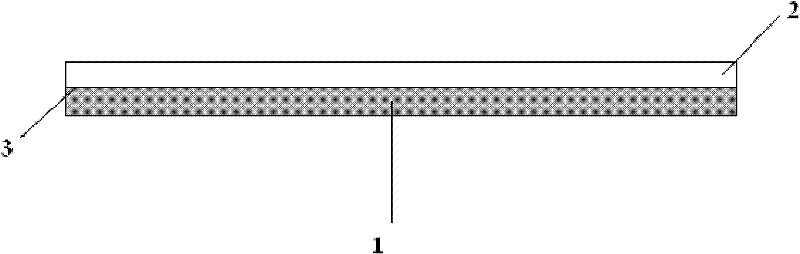

[0039] like Figure 1-2 As shown, a kind of rubber-less powder mica tape containing polyarylsulfone fiber, from top to bottom is successively mica layer 1, adhesive layer 3 and reinforcing material layer 2, wherein, mica layer 1 is made of powder mica and polyphenylsulfone It is composed of terephthalamide fibers, and a small amount of adhesive exists in the mica layer 1.

[0040] The adhesive is epoxy-modified polyester adhesive.

[0041] The manufacturing method of the above-mentioned product is: quantitatively 160g / m 2 Non-calcined muscovite paper (which contains 10g / m 2 Polyarylene sulfone fiber, the average diameter of the fiber is 9μm, the average length is 3.5mm), the basis weight is 22g / m 2 Alkali-free fixed-grain glass cloth, the mica paper and glass cloth are bonded with an epoxy modified polyester adhesive to produce a mica tape containing polyarylene sulfone fiber and less rubber powder, wherein the adhesive content is 8% of the total weight of the mica tape. %...

Embodiment 2

[0057] The sample A mica tape in Example 1 was wrapped on an aluminum strip wire rod (12mm×40mm×800mm) in the form of half-folded wrapping, with 18 layers of wrapping, and the insulating ends of the wrapping were sealed. Immerse the unsaturated polyester-epoxy-acid anhydride-styrene type impregnation resin, the impregnation pressure is 0.6MPa, and the impregnation time is 3 hours. The impregnated wire rod is baked and solidified. Take part of the sample for cutting and dissection to measure its immersion depth. This sample was designated as sample C.

[0058] Using the sample B mica tape in Example 1, a simulated wire rod was made in the same manner as above, and a part of the sample was taken for cutting and dissection to measure its immersion depth. This sample was designated as sample D.

[0059] The comparison results are shown in Table 2 below.

[0060]

[0061] It can be seen from the above table that with the same VPI treatment process, the same impregnating resi...

Embodiment 3

[0064] Wrap the adhesive tape of sample A in Example 1 on an iron plate coated with a release agent, wrap 10 layers, use the impregnated resin and VPI process in Example 2, bake and solidify, and cut into a certain size. The size of the sample, as sample E.

[0065] The sample B-less adhesive tape in the embodiment was made into a sample in the same manner as above, and this was taken as sample F.

[0066] Samples E and F were tested for flexural strength at different temperatures. The test results are shown in Table 3.

[0067] table 3

[0068] Sample E Sample F test temperature Bending strength (MPa) Bending strength (MPa) 23℃ 230.8 227.8 80℃ 83.6 65.2 130℃ 43.0 27.2 155℃ 40.1 25.6 180℃ 31.0 20.0

[0069] The test results show that the hot flexural strength and thermal flexural strength retention rate of the sample made with the adhesive tape containing polysulfone fiber are significantly highe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com