Novel multiaxis machining machine

A multi-axis machining and mechanical technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as affecting the balance of feed movements and machining accuracy, high requirements for processing machinery structures, and unreasonable structural configuration. , to achieve the effect of reducing volume and weight, improving service life and good bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

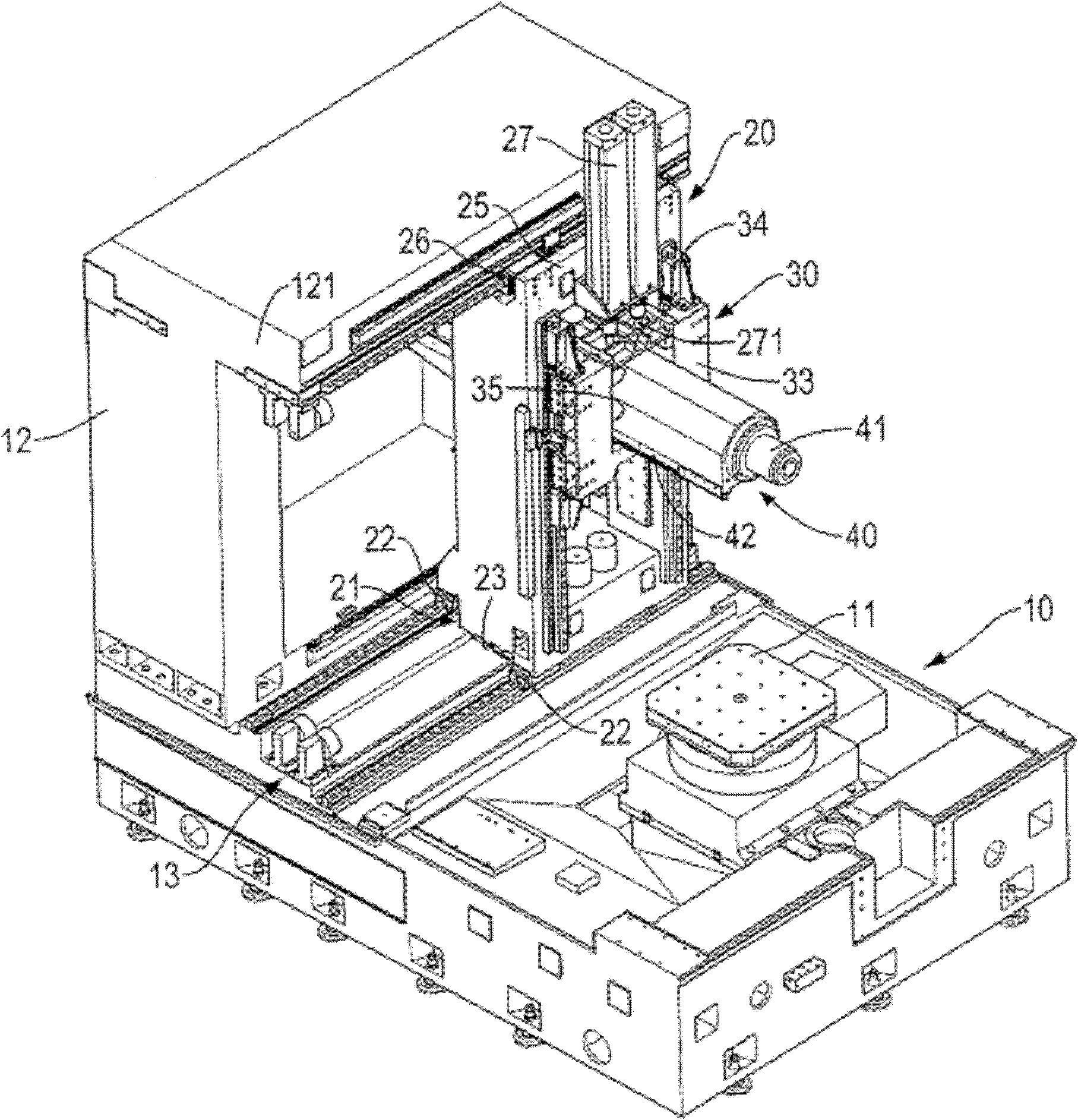

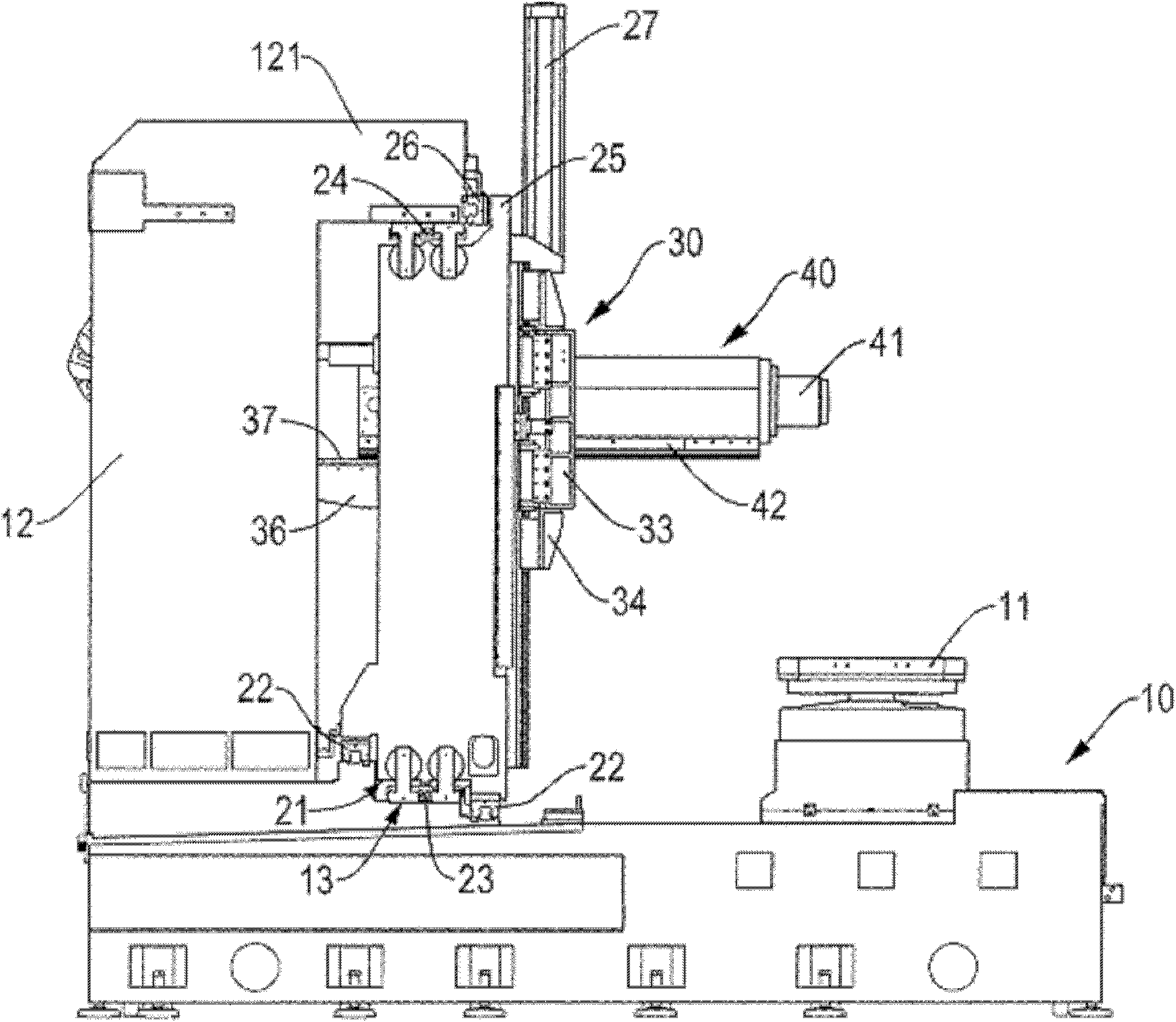

[0025] see figure 1 , shows a schematic perspective view of the novel multi-axis processing machine of the present invention.

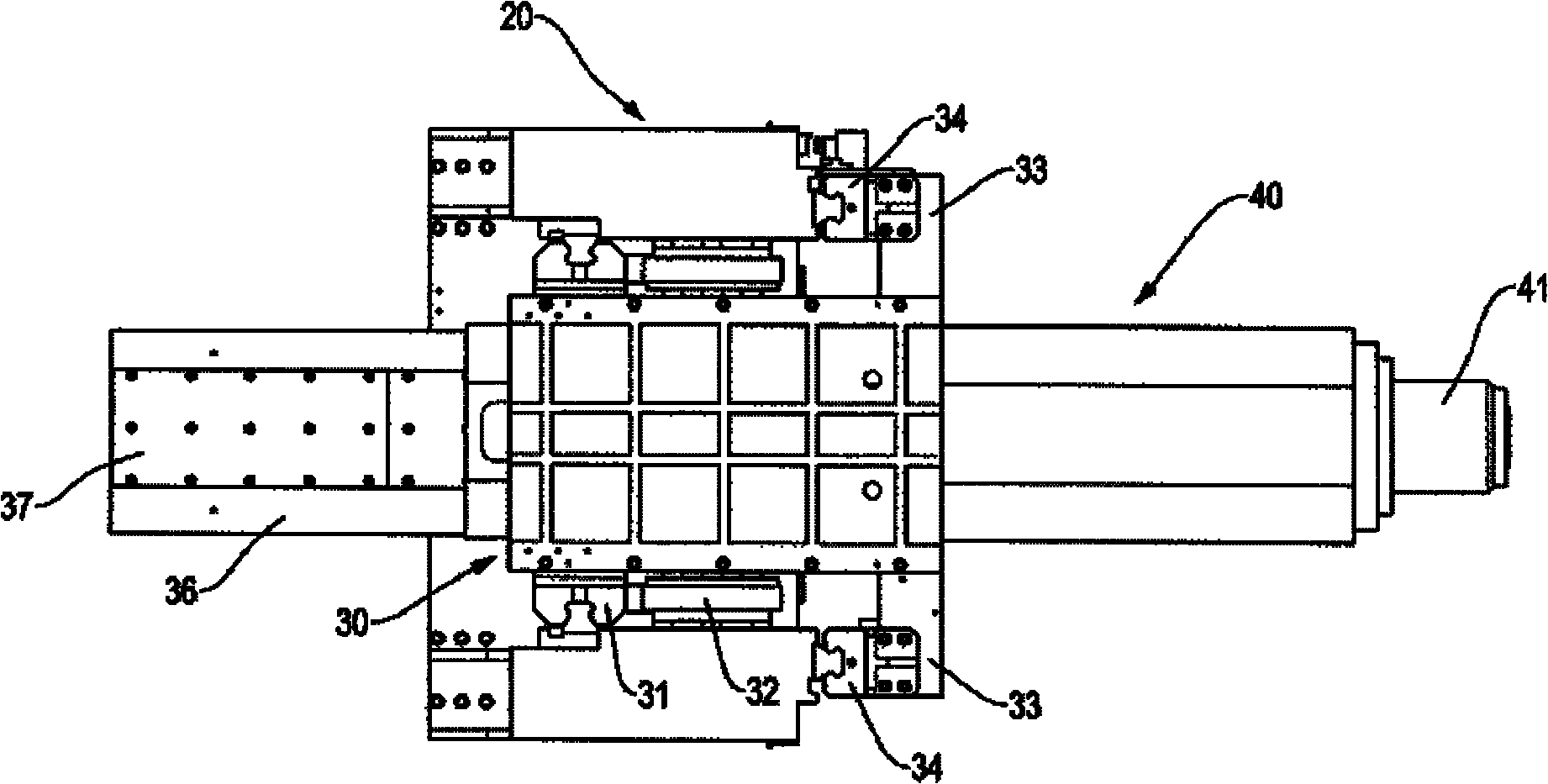

[0026] The processing machine includes a base 10 , a vertical table 20 , a tool head box 30 and a spindle head seat 40 .

[0027] Among them, see also figure 2 One side of the base 10 is provided with a workbench 11, the workpiece can be placed on the workbench 11 during processing, and the other side of the base 10 is provided with an upright base 12, the base 12 is a square frame with an inner space, The top end of the base 12 extends toward the direction of the workbench 11 to a joint part 121 , below the joint part 121 , the base 10 is provided with three steps 13 , and the three steps 13 climb up from the workbench 11 to the base 12 sequentially.

[0028] Wherein, the vertical platform 20 is a square frame body, and the bottom of the vertical platform 20 corresponds to the three-layer step portion 13 on the base 10 to form a corresponding comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com