Method for preparing nano-nickel/carbon fiber (Ni/CF) catalyst from chemical nickel-plating waste liquid

A technology of electroless nickel plating and carbon fiber, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve problems such as no research or patent reports, and achieve good economy And environmental protection value, reduce energy consumption, increase the effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

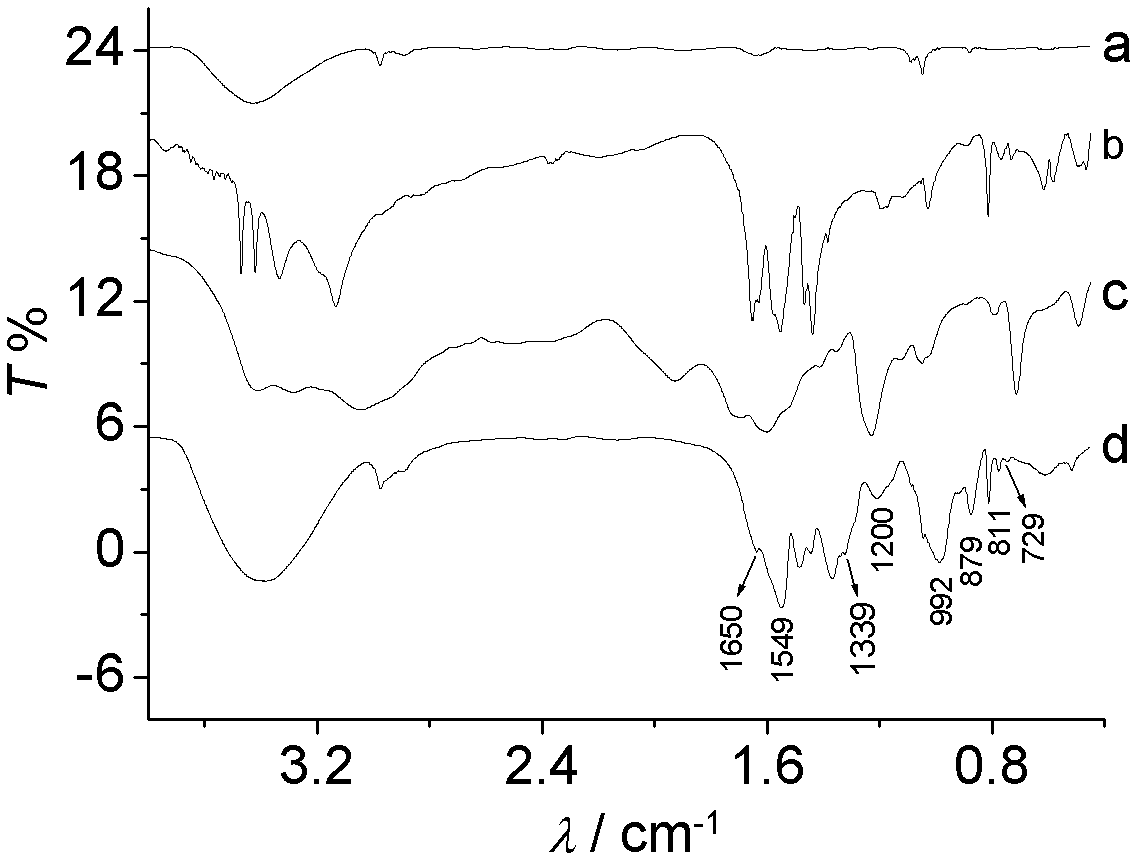

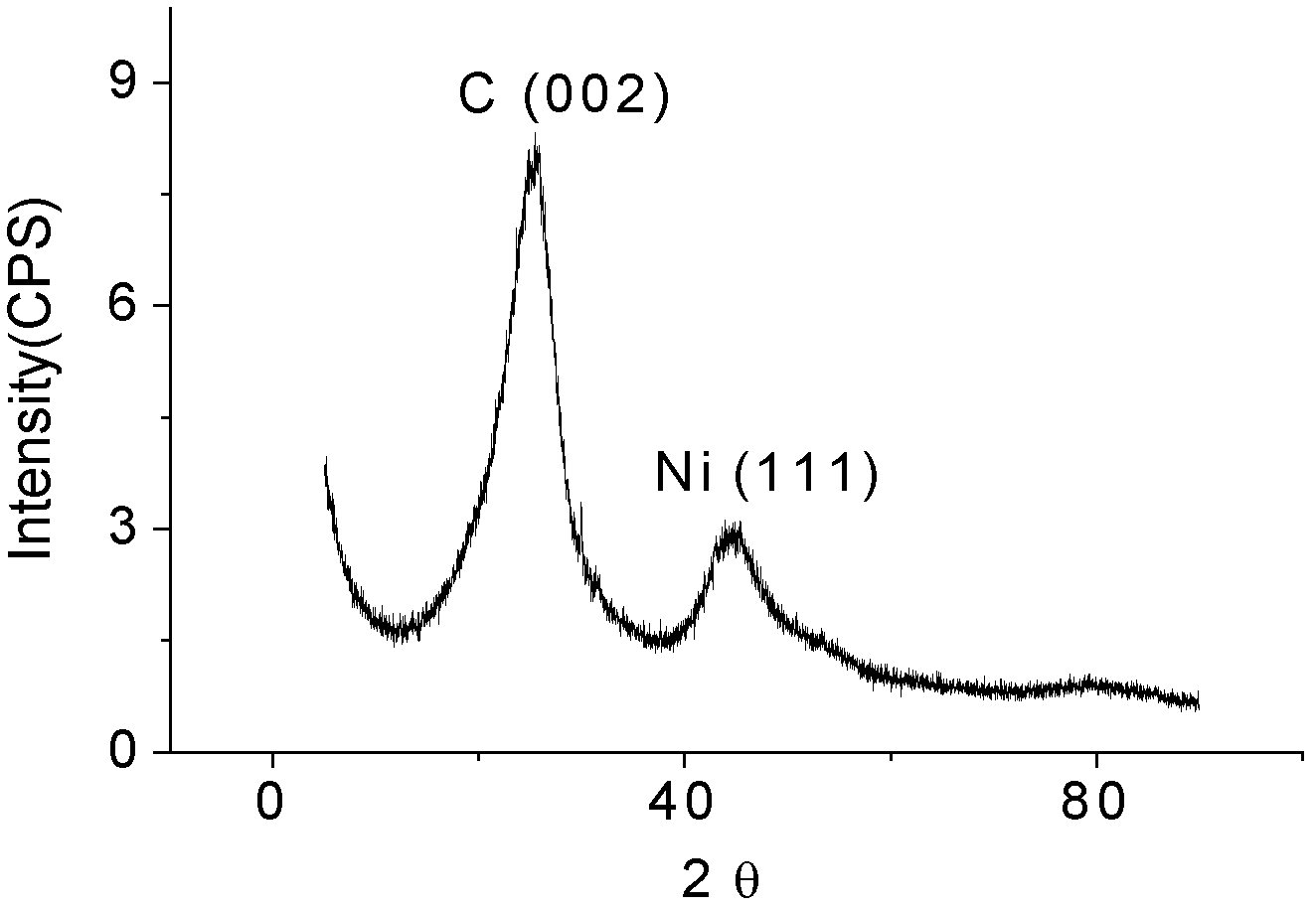

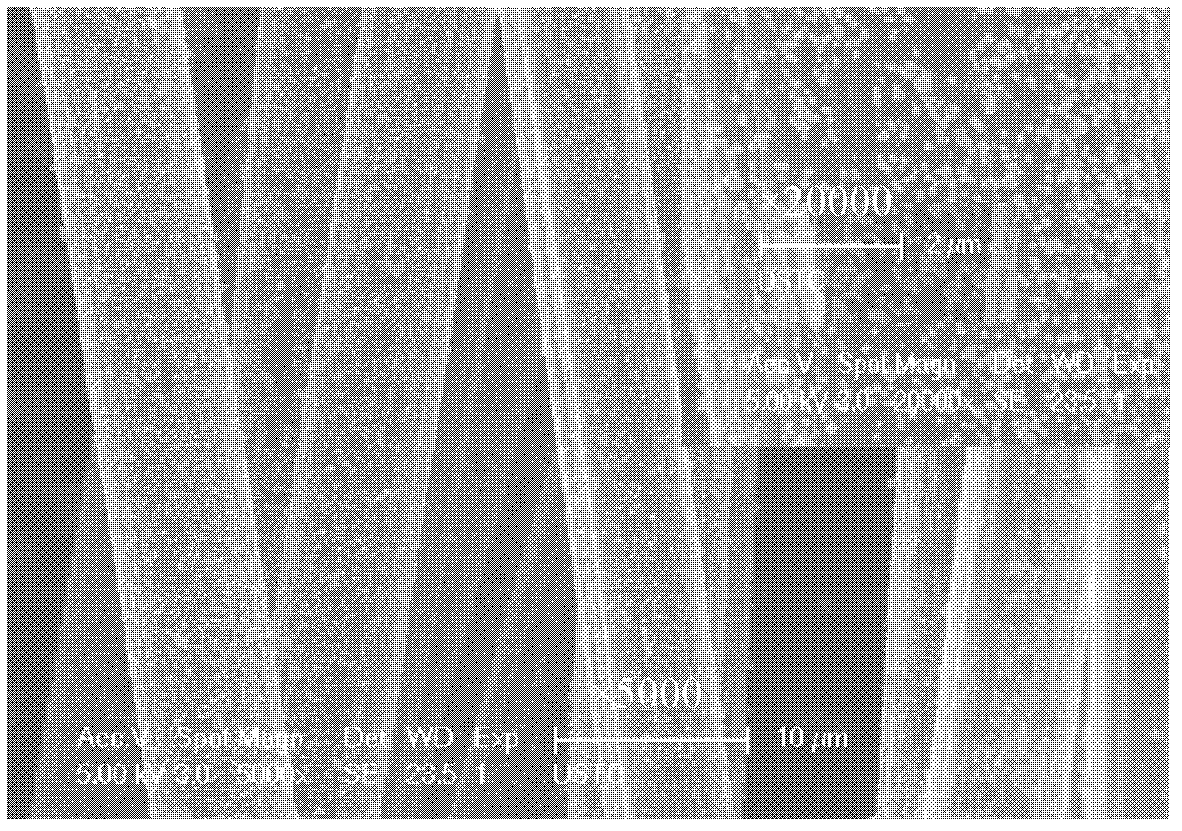

[0037] 2. Preparation of ethylenediamine / carbon fiber composites

[0038] Carboxylated carbon fibers were placed in absolute ethanol and twice distilled water for ultrasonic cleaning for 5 minutes, and then dried naturally in the air after cleaning, and then placed in an acetonitrile solution of ethylenediamine and lithium perchlorate, in which ethylenediamine The concentration is 1-10mmol·L -1 , the concentration of lithium perchlorate is 0.1mol L -1 At room temperature, a conventional electrochemical three-electrode system (carbon fiber as the working electrode, silver wire as the reference electrode, and platinum wire as the auxiliary electrode) is used at a constant potential of 1.2-1.8V for 1.5-4.5 hours to make ethylenediamine covalently modified On the surface of carbon fiber, then take it out and place it in an aqueous ethanol solution of potassium chloride, and keep the electrodes constant at -0.7 to -1.4V for 1-3 hours of constant potential reduction to aminate the ...

Embodiment 1

[0049] Prepare according to the above-mentioned embodiment, wherein:

[0050] In step 2, the carboxylated carbon fibers were put into absolute ethanol and twice-distilled water for ultrasonic cleaning for 5 minutes respectively, and after cleaning, they were naturally dried in the air, and then placed in an acetonitrile solution of ethylenediamine and lithium perchlorate, wherein The concentration of ethylenediamine is 1mmol L -1 , the concentration of lithium perchlorate is 0.1mol L -1 At room temperature, a conventional electrochemical three-electrode system (carbon fiber as the working electrode, silver wire as the reference electrode, and platinum wire as the auxiliary electrode) was used at a constant potential of 1.5V for 3 hours to covalently modify the surface of the carbon fiber with ethylenediamine. Then take it out and put it in the ethanol aqueous solution of potassium chloride, each electrode is constant potential reduction at -1.4V for 1 hour, the carbon fiber s...

Embodiment 2

[0055] Prepare according to the above-mentioned embodiment, wherein:

[0056] In step 2, the carboxylated carbon fibers were put into absolute ethanol and twice-distilled water for ultrasonic cleaning for 5 minutes respectively, and after cleaning, they were naturally dried in the air, and then placed in an acetonitrile solution of ethylenediamine and lithium perchlorate, wherein The concentration of ethylenediamine is 10mmol L -1 , the concentration of lithium perchlorate is 0.1mol L -1 At room temperature, a conventional electrochemical three-electrode system (carbon fiber as the working electrode, silver wire as the reference electrode, and platinum wire as the auxiliary electrode) was used at a constant potential of 1.8V for 1.5 hours to covalently modify the surface of the carbon fiber with ethylenediamine. Then take it out and put it in the aqueous ethanol solution of potassium chloride, and keep the electrodes unchanged at -0.7V for 3 hours of constant potential reduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com