Chicken meal and preparation method thereof

A technology of chicken powder and chicken, applied in the field of food additives, can solve the problems of high price, weak flavor of chicken powder, affecting use, etc., and achieve the effect of high cost performance, rich flavor and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

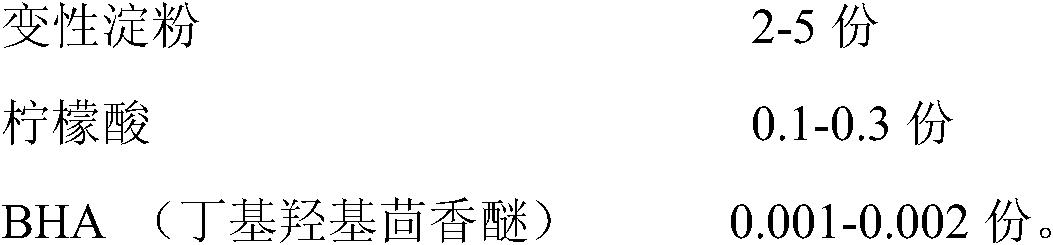

[0025] A kind of chicken powder, is prepared from following raw material:

[0026]

[0027] The concrete method of preparing this chicken powder, comprises the steps:

[0028] (1) Grind 70 parts of fresh chicken skeletons with a meat grinder, add 26.199 parts of water, heat up, keep warm at 95°C for 5 minutes, cool down to 60°C, pass through 40 sieves, and the sieve is cooked chicken and chicken bones , a total of 51.5 parts, the chicken fat and water were removed through a sieve.

[0029] (2) Add 0.1 part of papain to 51.5 parts of cooked chicken and chicken bones, and hydrolyze it for 0.5 hour at 65°C to obtain a chicken hydrolyzate mixture, then pass the chicken hydrolyzate mixture through a colloid mill for 1-2 times to grind, Obtain 51 parts of uniform chicken hydrolyzate.

[0030] (3) Add 0.4 parts of glucose, 0.1 parts of D-xylose, 0.5 parts of glycine, 0.5 parts of DL-alanine and 0.1 parts of L-cysteine hydrochloride to 51 parts of chicken hydrolyzate, and heat ...

Embodiment 2

[0034] A kind of chicken powder, is prepared from following raw material:

[0035]

[0036] The concrete method of preparing this chicken powder, comprises the steps:

[0037] (1) Grind 80 parts of fresh chicken skeletons with a meat grinder, add 16.199 parts of water, heat up, keep warm at 95°C for 5 minutes, cool down to 60°C, pass through 40 sieves, and the sieve is cooked chicken and chicken bones , a total of 56.5 parts, the chicken fat and water were removed through a sieve.

[0038] (2) Add 0.1 part of papain to 56.5 parts of cooked chicken and chicken bones, and hydrolyze it for 0.5 hour at 65°C to obtain a chicken hydrolyzate mixture, then pass the chicken hydrolyzate mixture through a colloid mill for 1-2 times to grind, Obtain 56 parts of uniform chicken hydrolyzate.

[0039] (3) Add 0.4 parts of glucose, 0.1 parts of D-xylose, 0.5 parts of glycine, 0.5 parts of DL-alanine and 0.1 parts of L-cysteine hydrochloride to 56 parts of chicken hydrolyzate, and heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com