Anti-explosion valve for power lithium ion battery

A lithium-ion battery and explosion-proof valve technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of battery scrap, waste, and increased internal pressure of the battery, and achieve convenient installation, prevent explosion, and ensure normal use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

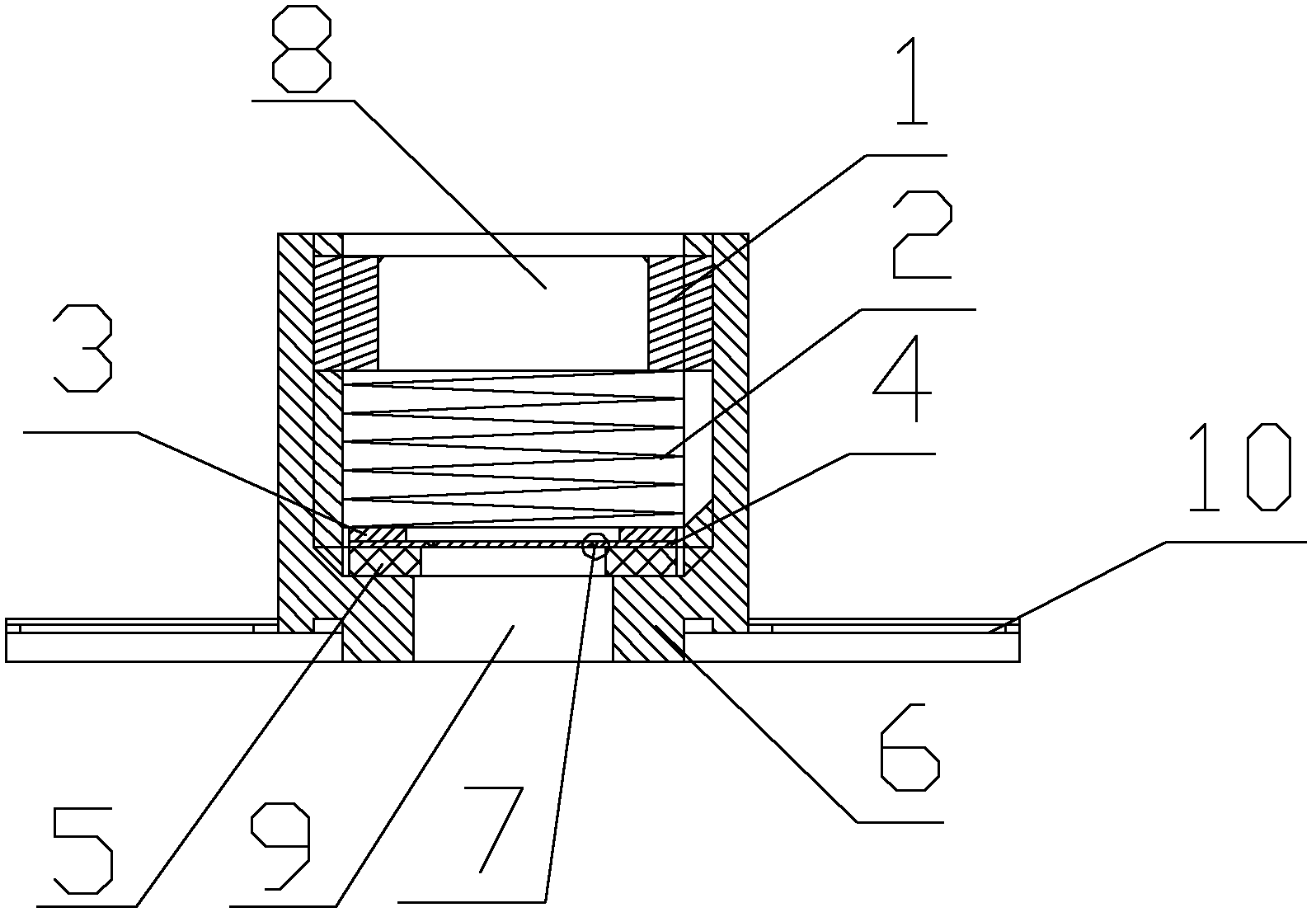

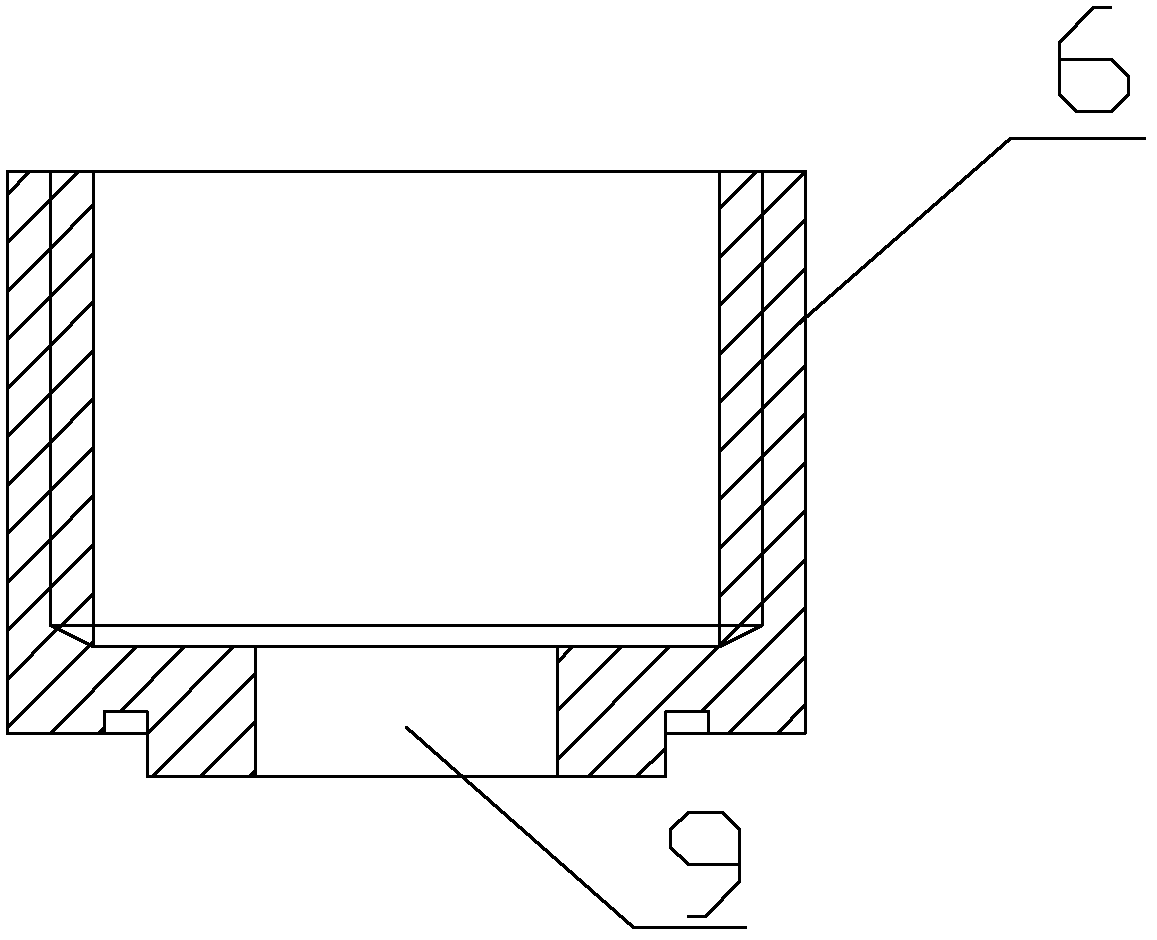

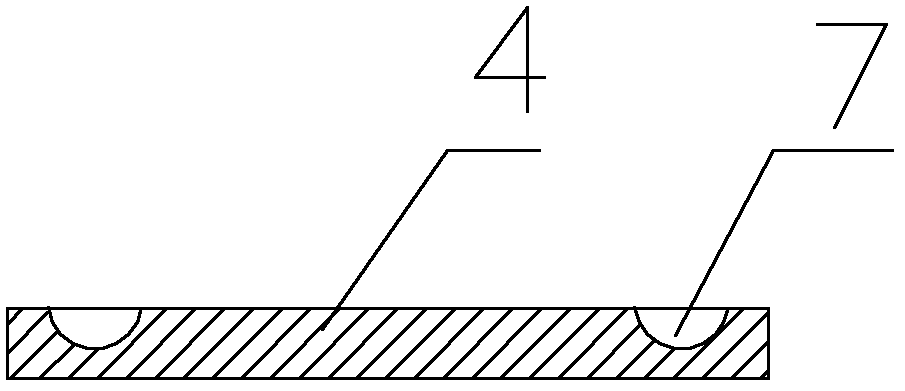

[0024] see figure 1 , a power lithium-ion battery explosion-proof valve with lithium titanate as the negative electrode, which includes an explosion-proof valve outer wire 6, an explosion-proof plate 4, a spring 2 and an explosion-proof valve inner wire 1, an explosion-proof plate 4, a spring 2 and an explosion-proof valve inner wire 1 It is installed in the outer wire 6 of the explosion-proof valve in sequence from bottom to top, and a through hole 8 is arranged in the middle of the inner wire 1 of the explosion-proof valve.

[0025] see figure 1 , in order to achieve a better sealing effect, inside the explosion-proof valve outer wire 6, an explosion-proof valve sealing ring 5 is provided below the explosion-proof disc 4, and a burs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com