Reflection silver mirror used for solar energy thermal power generation and manufacturing method thereof

A solar thermal power generation, silver mirror technology, applied in chemical instruments and methods, mirrors, sputtering coating, etc., can solve the problems of reflectivity discount, large reflectivity difference between reflecting silver mirrors, time-consuming and labor-intensive, etc. Reflectivity, Reflectance Guaranteed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

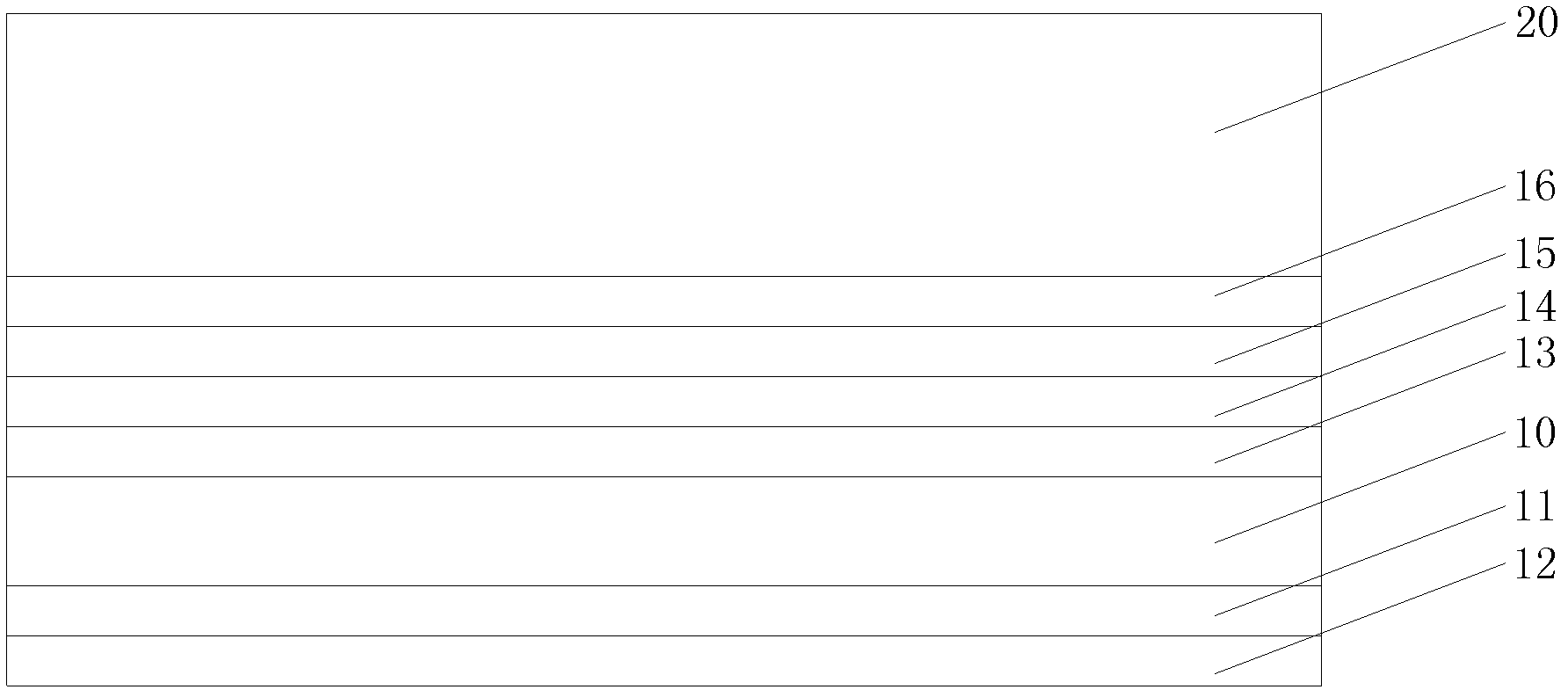

[0022] refer to figure 1 , the reflective silver mirror for solar thermal power generation of the present invention includes ultra-white ultra-thin glass 10 and a parabolic substrate glass 20 . After the ultra-white ultra-thin glass 10 is chemically tempered, the surface finish will not be affected, the mechanical strength is 3-5 times higher than that of physical tempering, and it has very good flexibility. The thickness of the ultra-white ultra-thin glass 10 is 0.85-1.6 mm, preferably 1 mm. Ultra-white ultra-thin glass chemically toughened is a flat glass during magnetron sputtering coating (it is flat before assembling with the substrate glass), unlike curved glass which is uneven, and the target base distance for sputtering is everywhere. Equal, the film formation is uniform, and the quality of the deposited film is guaranteed.

[0023] refer to figure 1 , the front surface of the flat ultra-white ultra-thin glass 10 is coated with a high-transparency self-cleaning film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com