Method for calibrating hardness indicating value of rubber hardness gauge and standard blocks

A calibration method and technology of hardness tester, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problems of inconvenient transportation, inconvenience for verification and use, high cost and price, and achieve the effect of easy verification and use, ingenious structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, specific embodiments of the present invention will be described in conjunction with the accompanying drawings.

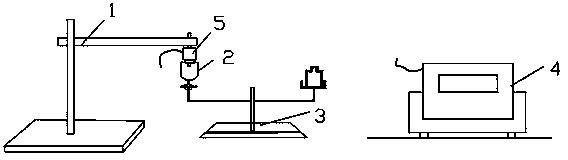

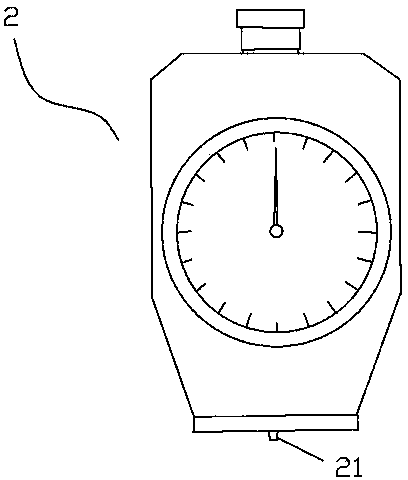

[0040] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 Shown, the calibration method of rubber durometer 2 hardness indication value of the present invention comprises:

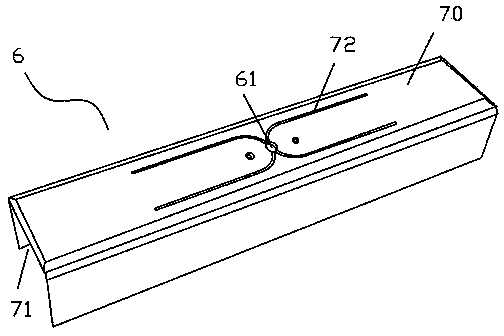

[0041] One, the calibration is carried out through the standard blocks of the hardness indication value of the rubber hardness meter, and the standard blocks of the hardness indication value of the rubber hardness meter include the A-type standard block group, the C-type standard block group, the D-type standard block group and the F-type standard block group Group, wherein each type of standard block group includes at least 6 standard blocks 6 with different hardness values to cover the hardness range of 30-80, and each standard block is specifically 30 + 2,40 + 2,50 + 2,60 + 2,70 + 2 or 80 + 2 hardness value;

[0042] Second, the cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com