Air inflation and exhaust blade structure of wind-driven generator

A wind turbine and blade structure technology, which is applied to wind turbine components, wind engines, and wind turbines in the same direction as the wind, and can solve the problems of high manufacturing, transportation and installation costs, complex large blade structures, and high equipment maintenance costs , so as to achieve the effects of small unit structural stress, low manufacturing and maintenance costs, and reduced blade weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, structure of the present invention and specific embodiment are described further:

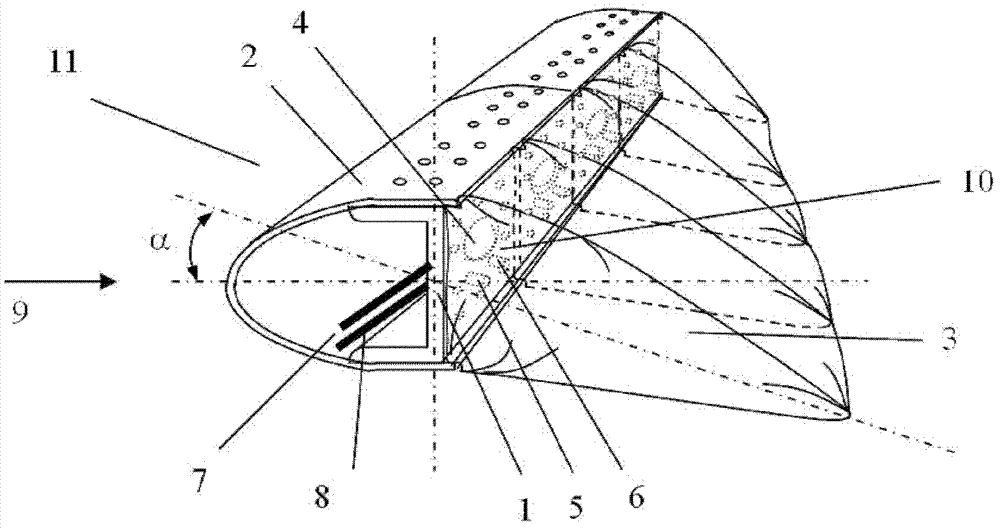

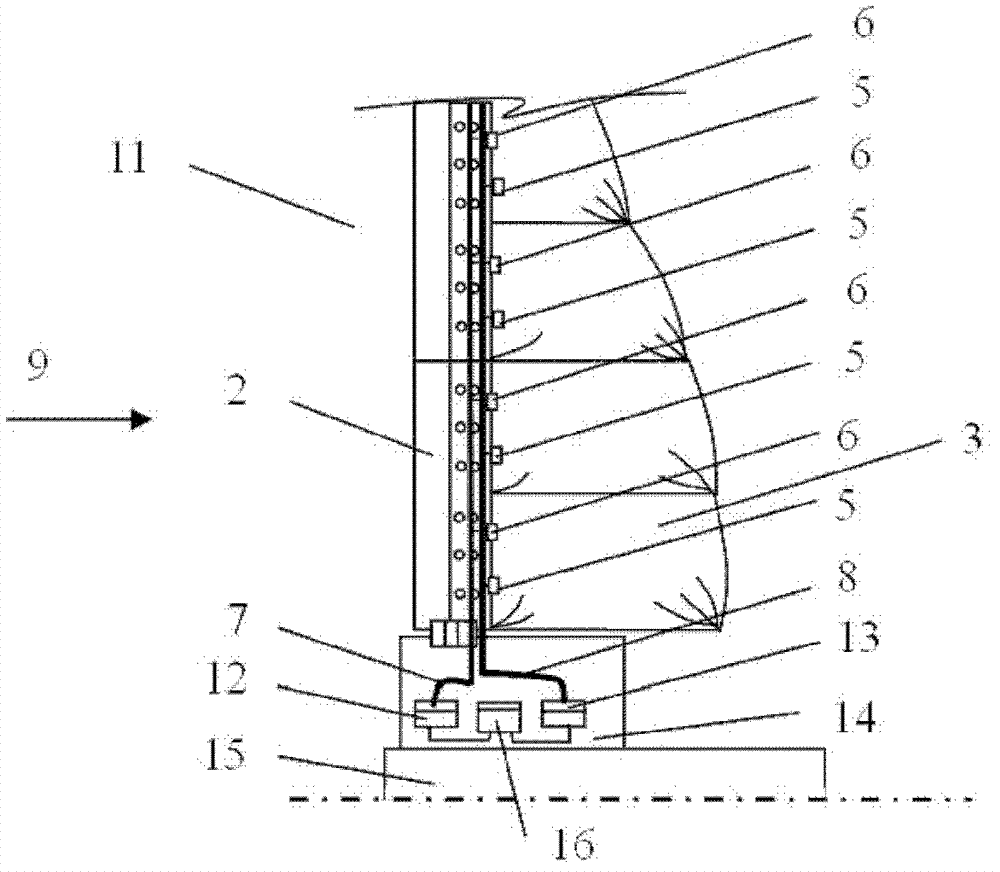

[0023] figure 1 It is a schematic diagram of the blade structure of the air charging and pumping type wind power generator provided by the present invention. The blade includes a skeleton beam 1, a front wing panel 2 and a rear wing airbag 3; the skeleton beam adopts a constant cross-section along the length direction of the blade, or adopts a gradually smaller variable cross-section, which is stronger on the side near the blade root, and closer to the blade root. The tip side of the blade is weaker. The rear wing airbag 3 adopts an integral airbag, and can also be composed of individual segmented airbags. The use of each independent segmented airbag can better control the stress state of the blade; generally, large blades use independent Segmented airbags are combined, while small and medium blades are in the form of integral airbags; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com