Copperplate board coating

A copper plate card and coating technology, which is applied in the direction of paper coating, coating, pigmented coating, etc., can solve the problems of steam and energy consumption, low coating solid content, and low coating amount, so as to save the use of slurry , Increase the solid content of the coating, and the effect of good printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

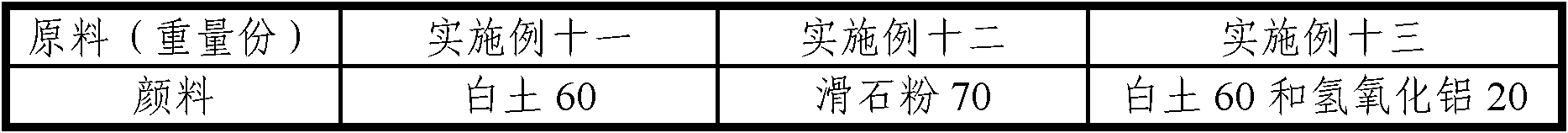

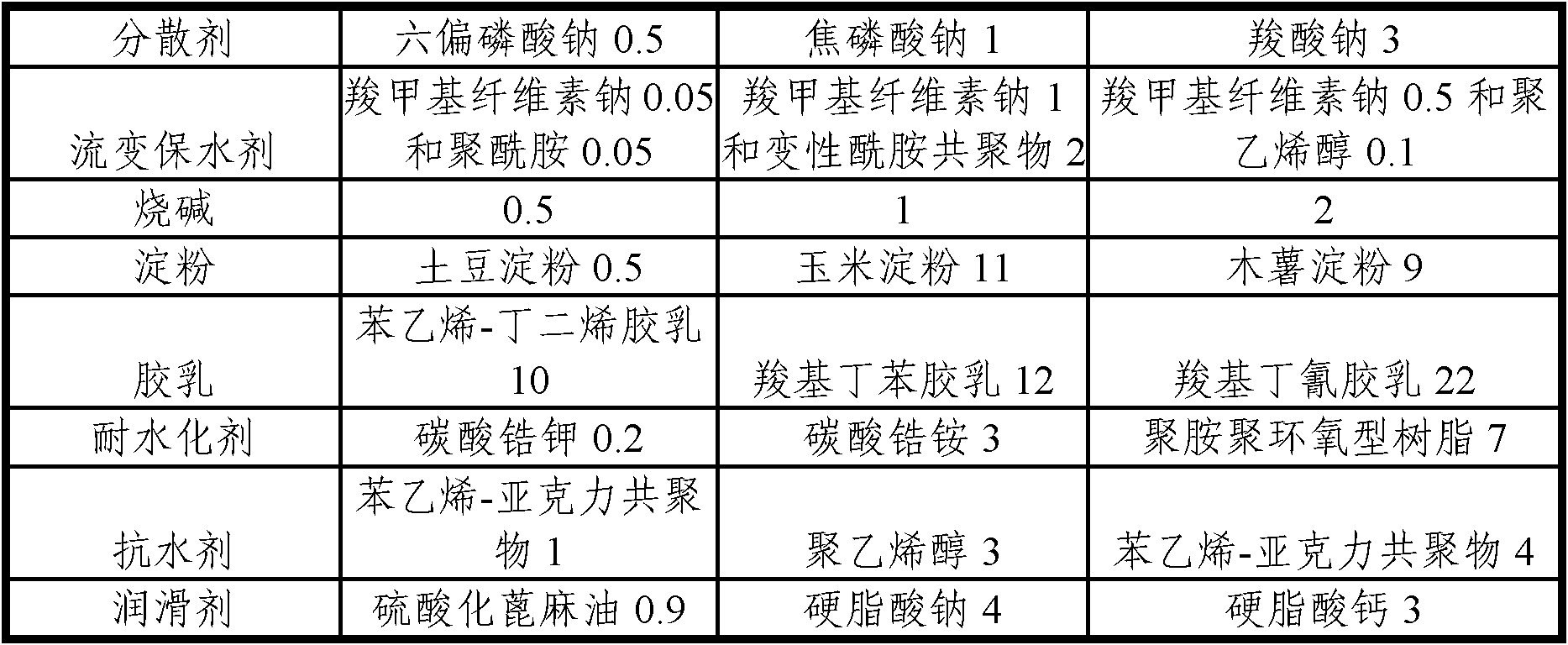

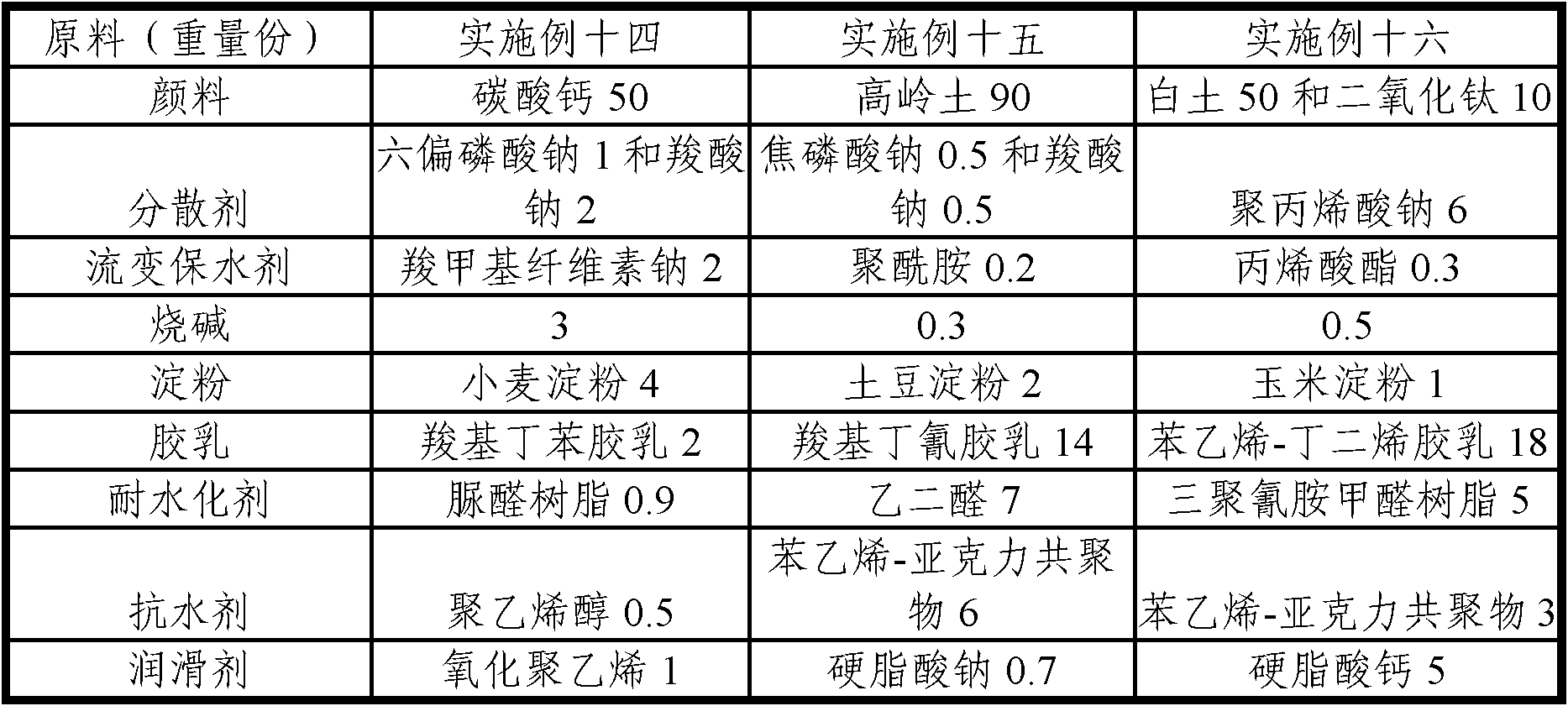

[0022] Coating formulations for copperplate cards are shown in Table 1-Table 4.

[0023] Table 1 Coating formula of copper plate card

[0024] Raw materials (parts by weight)

Embodiment one

Embodiment two

Embodiment three

Embodiment Four

Embodiment five

100

100

100

100

100

Sodium polyacrylate

0.2

0.3

0.5

0.2

0.3

Sodium carboxymethyl cellulose

0.2

0.15

0.1

0.1

0.15

caustic soda

0.5

0.5

0.6

0.6

0.5

6

2

0

4

8

Styrene-butadiene latex

6

12

9

10

15

PAPU

0.2

0.5

0.5

0.5

0.5

0.2

0.2

0.2

0.2

0.2

1

0.5

0.2

0.2

0.2

[0025] Table 2 Coating formula of c...

experiment example 1

[0034] ①Paint preparation and coating:

[0035] According to the paint formula in Example 1, each raw material was added in turn, and the paint was uniformly dispersed at a high speed, with a solid content of 68%; the coating speed was 600 m / min, and it was produced under the scraper coating method.

[0036] ② Coating sequence and paper weight:

[0037] Apply the base coat first, and then the top coat;

[0038] The paper gram weight is 200 grams.

[0039] ③Printing and paper properties:

[0040] The physical properties of the finished paper are excellent, and the printing color is gorgeous.

experiment example 2

[0042] ①Paint preparation and coating:

[0043] According to the coating formula of Example 2, each raw material was added in sequence, and the coating was uniformly dispersed at a high speed, and the solid content was 70%; the coating speed was 620 m / min, and it was produced under the scraper coating method.

[0044] ② Coating sequence and paper weight:

[0045] Apply the base coat first, and then the top coat;

[0046] The paper gram weight is 250 grams.

[0047] ③Printing and paper properties:

[0048] The physical properties of the finished paper are excellent, and the printing color is gorgeous.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com